Clutch wheel disc using centrifugal boosting force for tyre burst automatic balancing

An automatic balancing and roulette technology, which is applied to tire parts, transportation and packaging, vehicle parts, etc., can solve problems such as vehicle crashes and rollovers, tires are easy to wear, and achieve the effect of improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

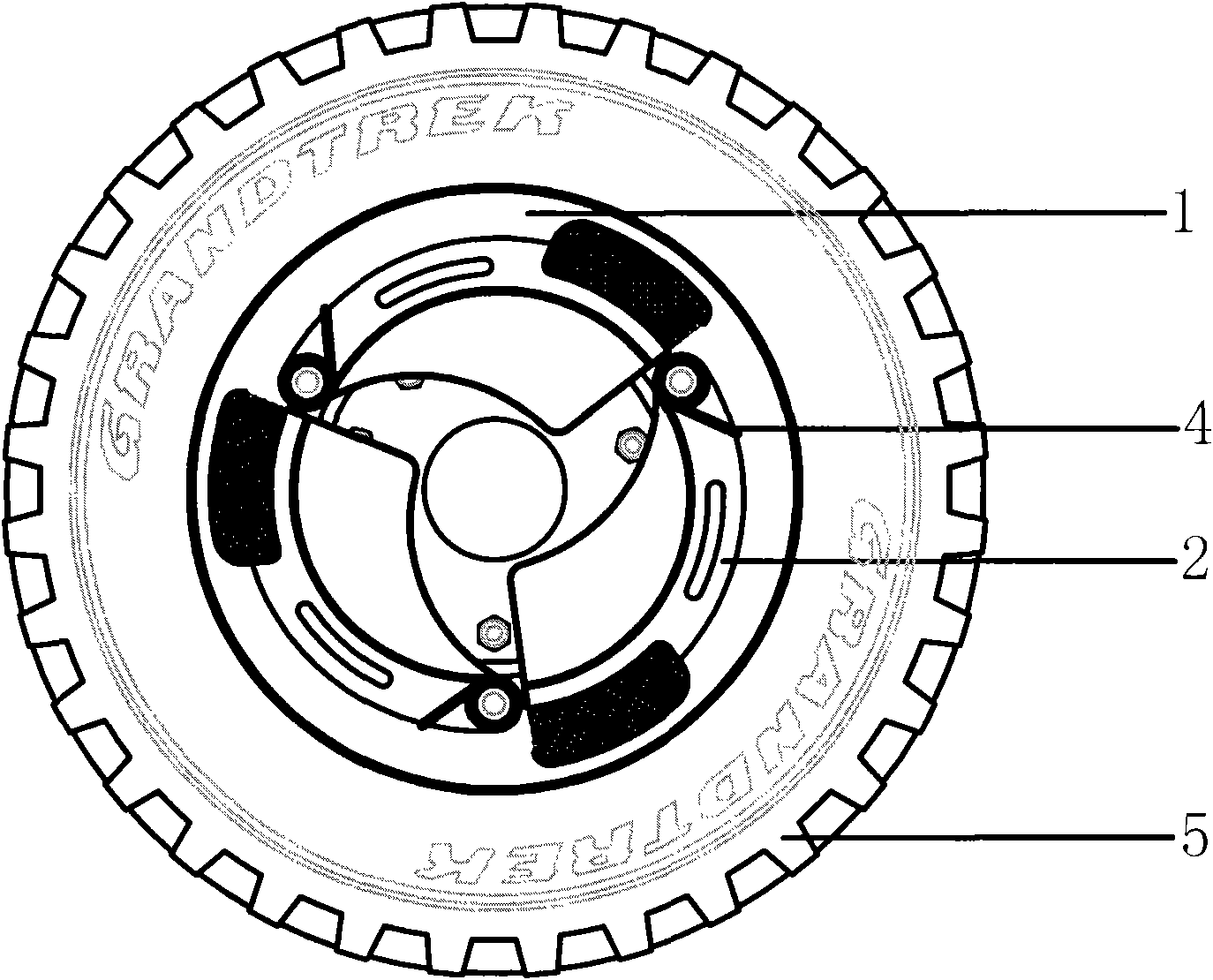

[0010] in figure 1 Among them, the clutch wheel (1) is made of metal, and its diameter is smaller than that of the wheel (5). A number of metal centrifugal blocks (2) are installed on the outer circumference. The metal centrifugal blocks (2) spring into the center of the clutch wheel (1) with a coil spring (4). When the wheel (5) reaches a certain speed, the metal The centrifugal block (2) expands outward. The outer side of the metal centrifugal block (2) is bonded with a friction rubber block (3) to assist the friction of the ground.

[0011] in figure 2 When the rotation speed of the wheel (5) slows down, the metal centrifugal block (2) loses centrifugal force, and the elastic force of the coil spring (4) causes the metal centrifugal block (2) to spring and close to the inner circle of the clutch wheel (1).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com