External gear shift for a manual transmission

A technology of shifting device and transmission, applied in transmission control, components with teeth, belt/chain/gear, etc., can solve the problem of laborious shifting process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

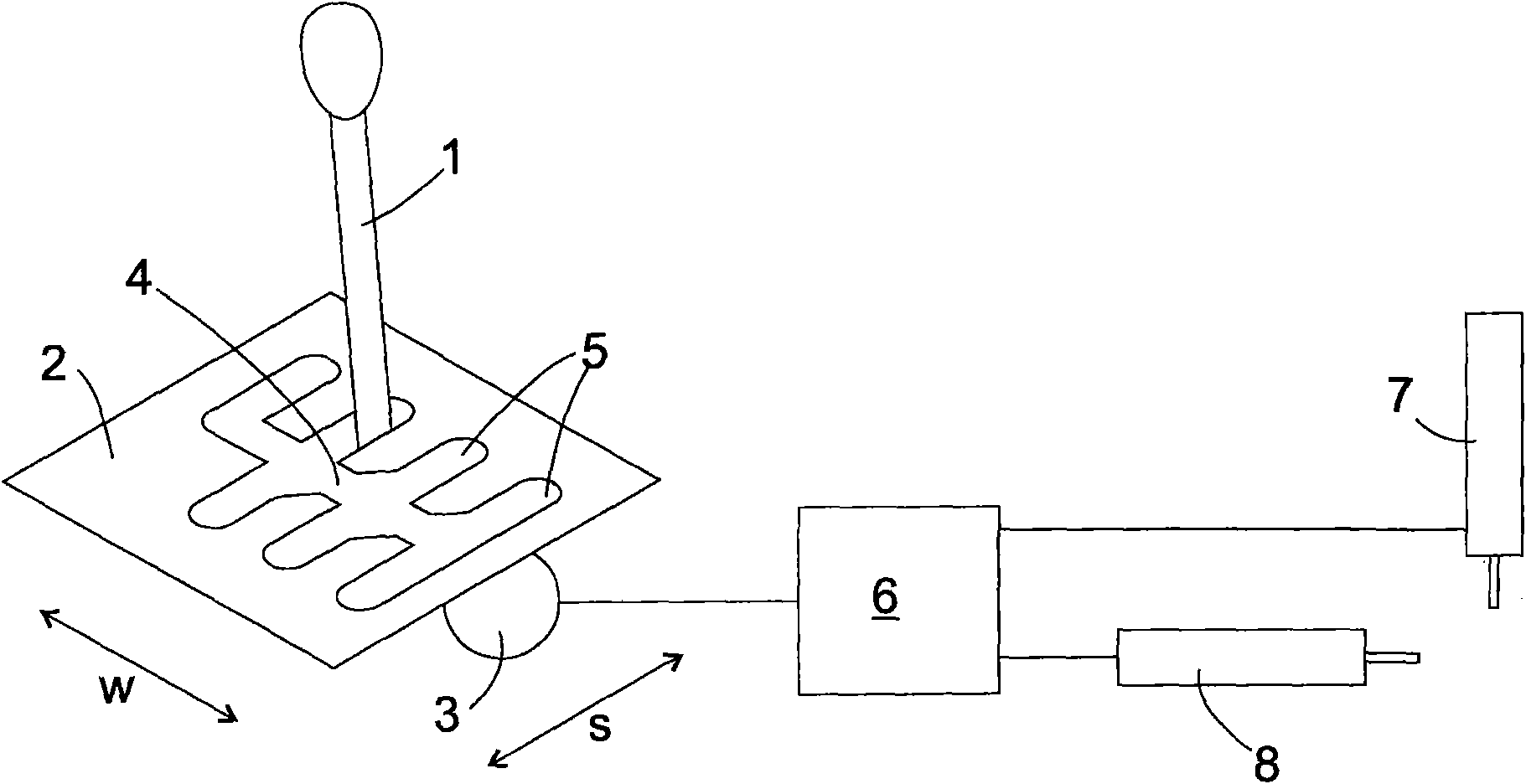

[0021] exist figure 1 The schematically shown shifting device comprises an external shifting device with a shift / gear lever 1 projecting into the vehicle cabin and guided in a gate plate 2 and a sensor 3 for detecting the position of the shift / gear lever 1 , the shift / gear lever can move in the direction of the selection channel 4 reserved in the chute plate 2 and the direction of the shift channel 5 intersecting with the selection channel 4 . The sensor 3 supplies the coordinate values s, w of the selector lever 1 with respect to these two directions to the control circuit 6 . An actuator arrangement with two degrees of freedom, shown here as two single servo cylinders 7 , 8 , is connected to the control circuit 6 . The actuating cylinders 7 , 8 effect a shifting movement of a shifting shaft of a multi-stage transmission known per se, not shown, in two degrees of freedom, eg axial displacement and rotation.

[0022] As long as the selector / gear lever 1 is in one of the ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com