Cylinder-type sander

A sanding machine, cylinder type technology, applied in the field of sheet metal processing, to achieve the effect of not easy to deviate, real-time adjustment of settings, and large floating stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

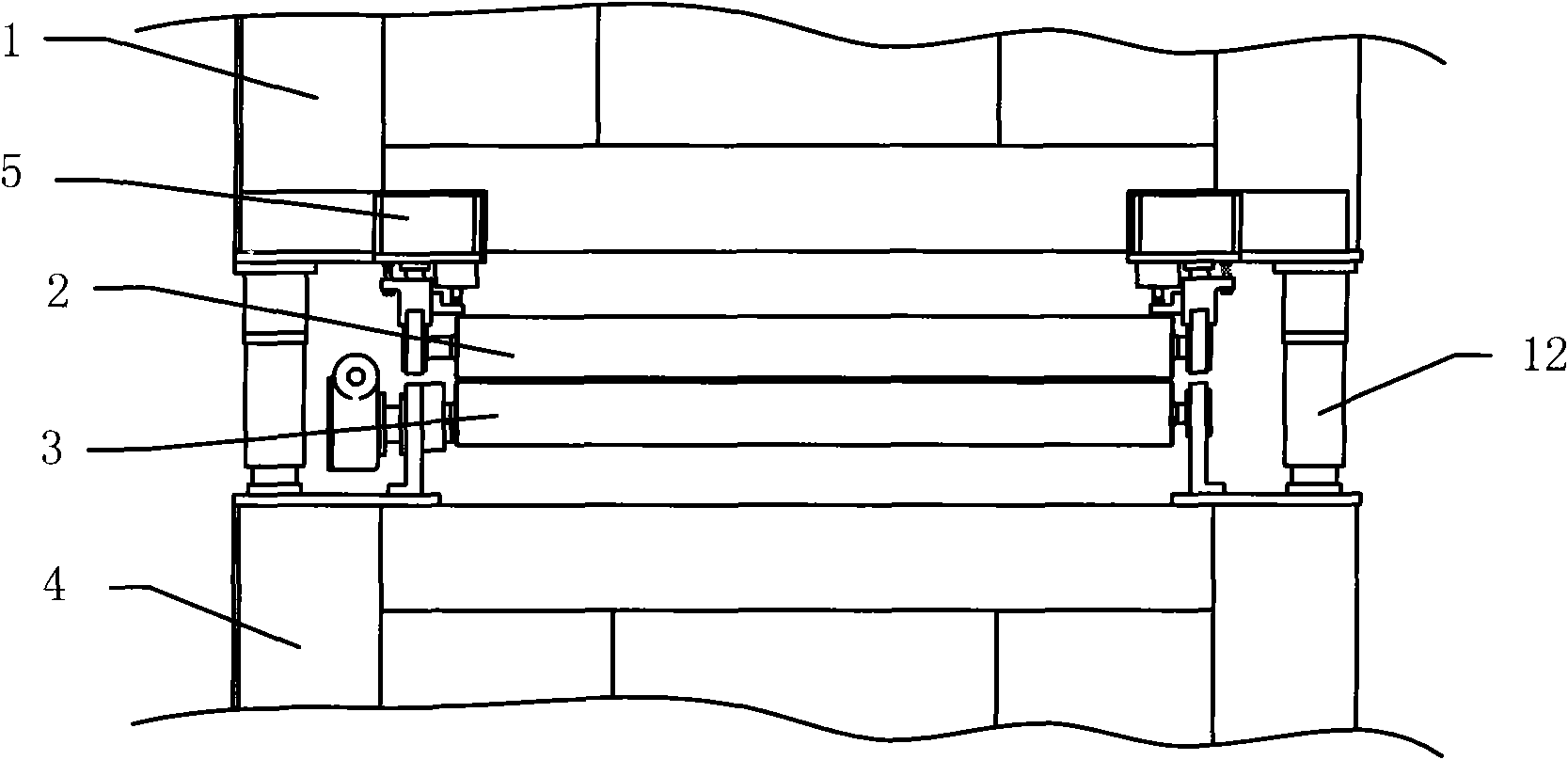

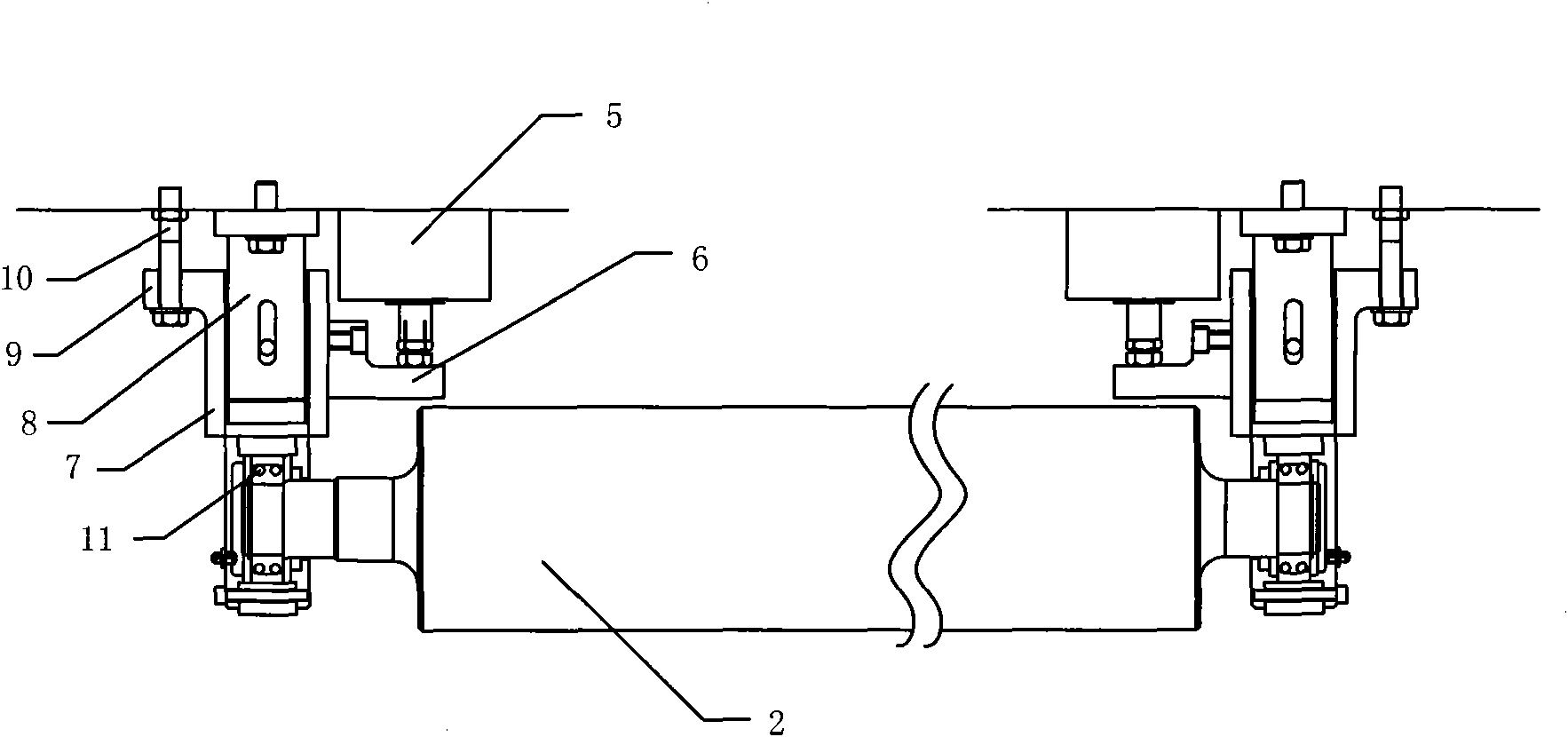

[0023] Such as figure 1 , figure 2 The cylinder sander shown includes an upper frame 1, an upper pressure roller 2, a lower cover rubber roller 3, and a lower frame 4. The lower end of the upper frame 1 is provided with an upper pressure roller 2, and the lower frame 4 is The lower cover rubber roller 3 is installed at the position where the end face faces the upper pressing roller 2. The special feature is that a floating pressing mechanism is installed between the upper frame 1 and the upper pressing roller 2, which includes a cylinder 5. Guiding device and adjusting device, the fixed end of the cylinder 5 is connected to the upper frame 1, the piston head of the cylinder 5 is floatingly connected to the guiding device, the guiding device is connected to the upper pressing roller 2, and the connection between the guiding device and the upper pressing roller 2 is installed with Adjusting device, it is the self-aligning ball bearing 11, and the self-aligning ball in it is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com