Manufacture method for silicon rubber synthetic insulators and umbrella slice sleeving machine

A technology for synthesizing insulators and manufacturing methods, which is applied in the direction of insulators, electrical components, circuits, etc., can solve the problems of inaccurate spacing between umbrella groups, affecting the quality of insulators, and longitudinal mold joints, etc., so as to achieve simple structure and improve external appearance. Quality, the effect of improving internal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

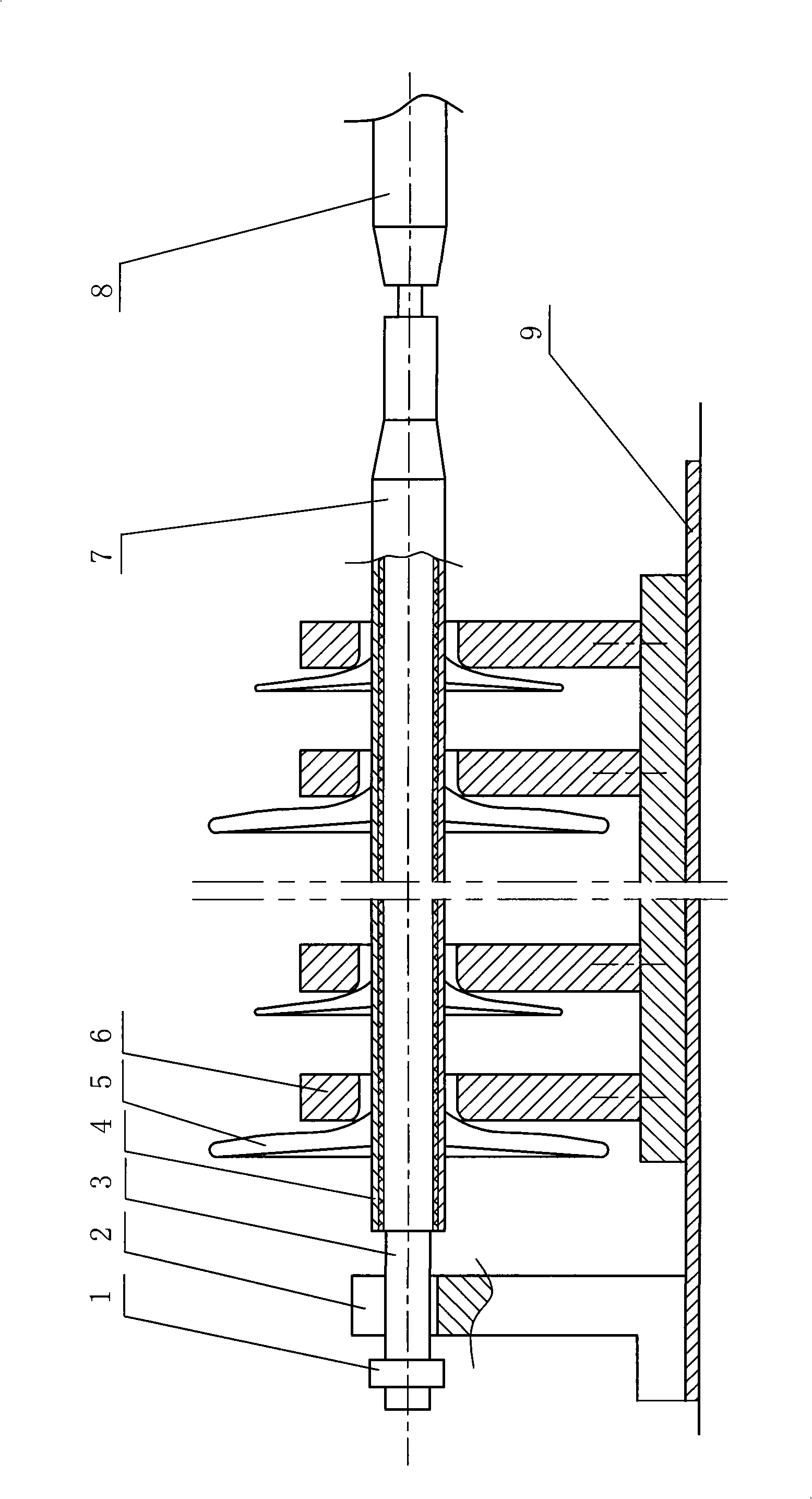

[0026] This will be further described in conjunction with the accompanying drawings of the above-mentioned embodiments.

[0027] As shown in the figure, in the silicone rubber synthetic insulator umbrella sheet assembly machine of the present invention, the umbrella sheet mold 6 is placed on the frame 9, and the rubber stick casing 4, the draw bar 8 and the glue stick movement limiter are set corresponding to the umbrella sheet mold 6. Position stopper 2, the top of limit stopper 2 has a U-shaped slot that is compatible with the glue stick sleeve, the glue stick sleeve 4 and the drawbar 8 are flexibly connected, and the front end of the glue stick sleeve 4 is provided with a ball socket for traction. The ball head is arranged on the rod 8, and the ball head is placed in the ball socket, which can realize the flexible connection between the glue stick sleeve and the drawbar.

[0028] The silicon rubber synthetic insulator manufacturing method described in the present invention,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com