System for dynamically detecting stiffness parameters of closed-loop diagonal-bracing type vehicle bogies

A rail vehicle and dynamic detection technology, which is applied in the direction of railway vehicle testing, measuring devices, elastic testing, etc., can solve the problem that the vertical, longitudinal, transverse and rotational stiffness tests of the primary and secondary suspension devices cannot meet the requirements. , Insufficient bogie performance, low degree of automation, etc., to achieve the effect of saving test funds, considerable social and economic benefits, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] Below in conjunction with the embodiment given with accompanying drawing, the patented structure of the present invention is described in further detail.

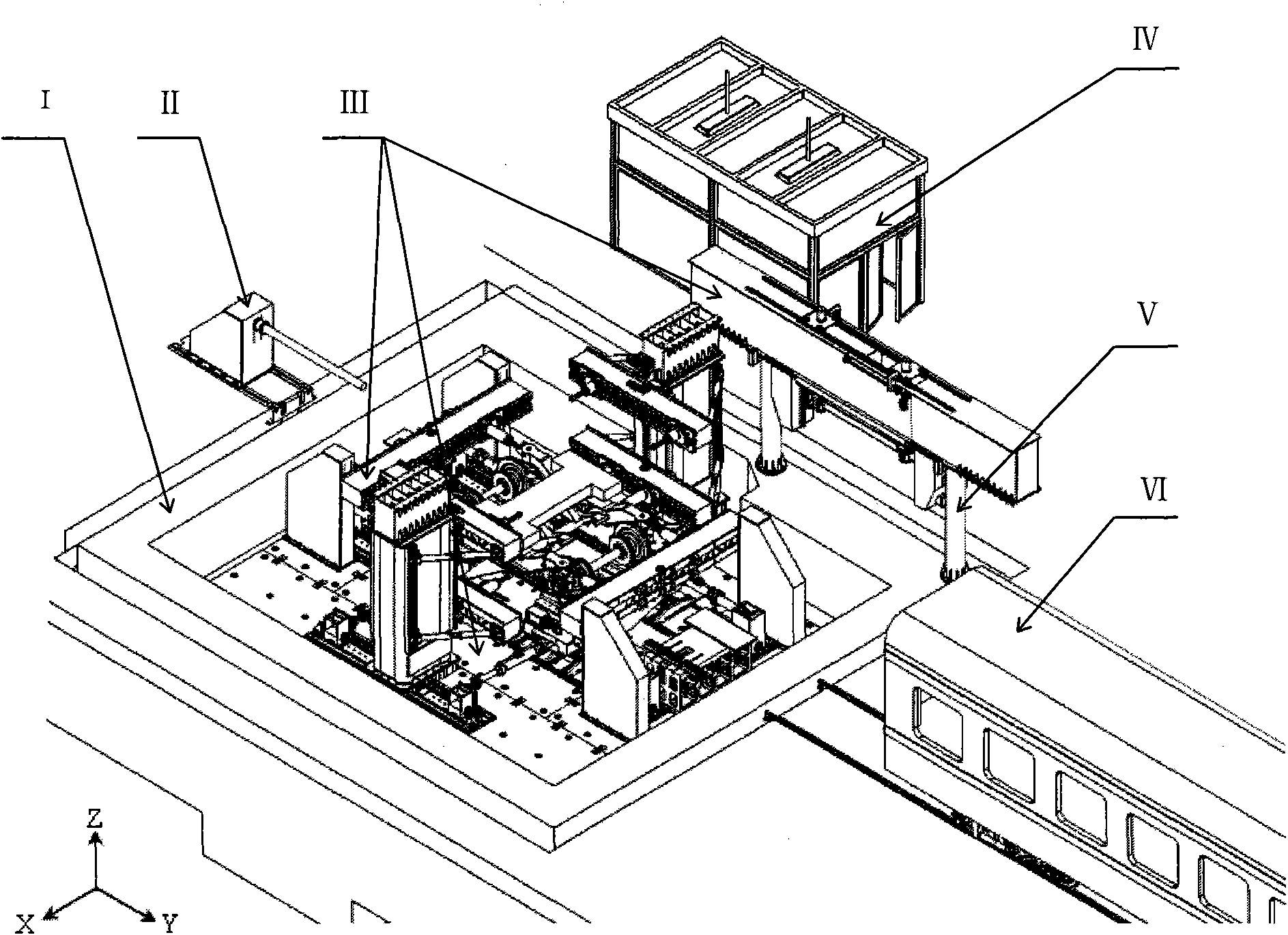

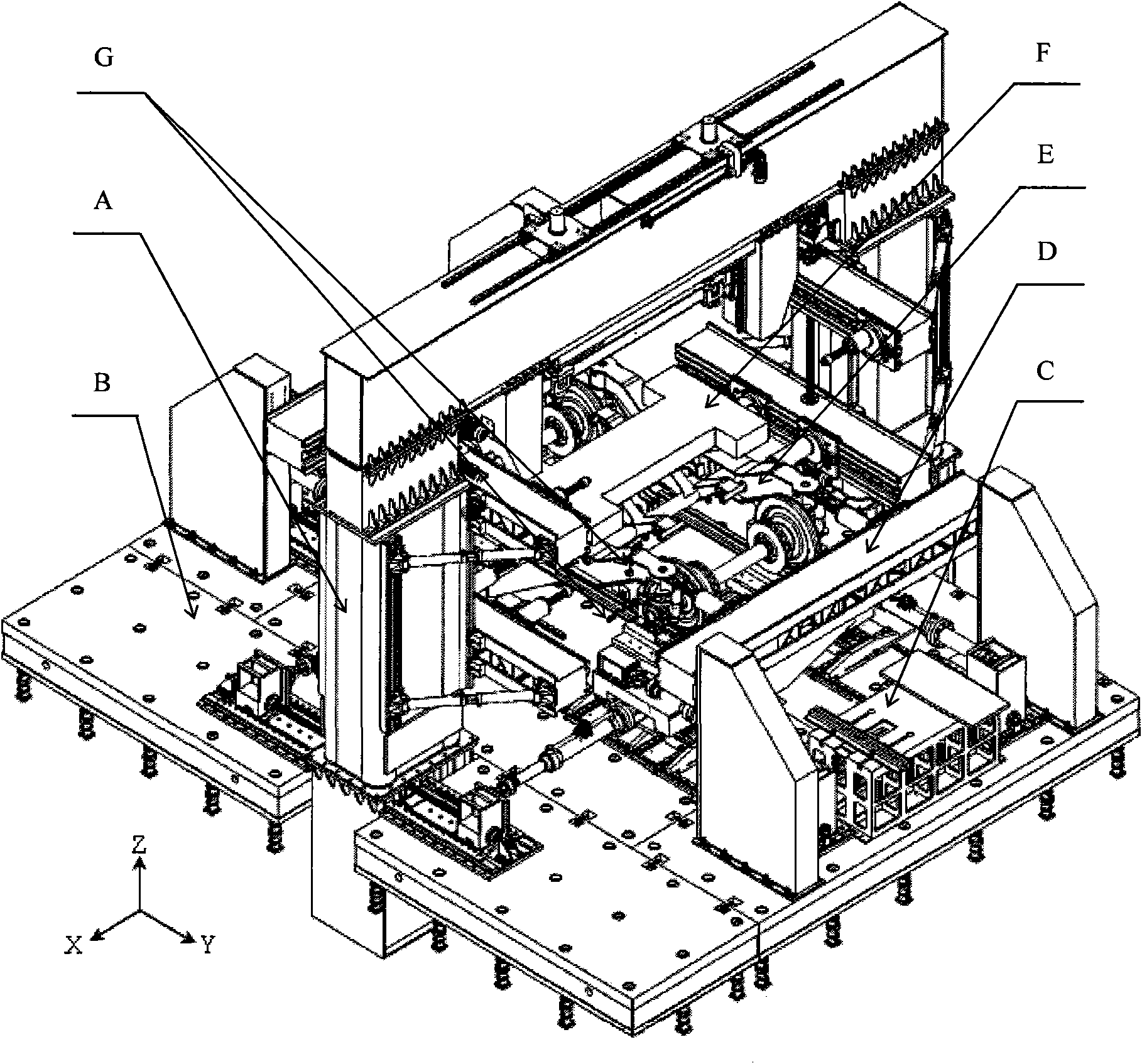

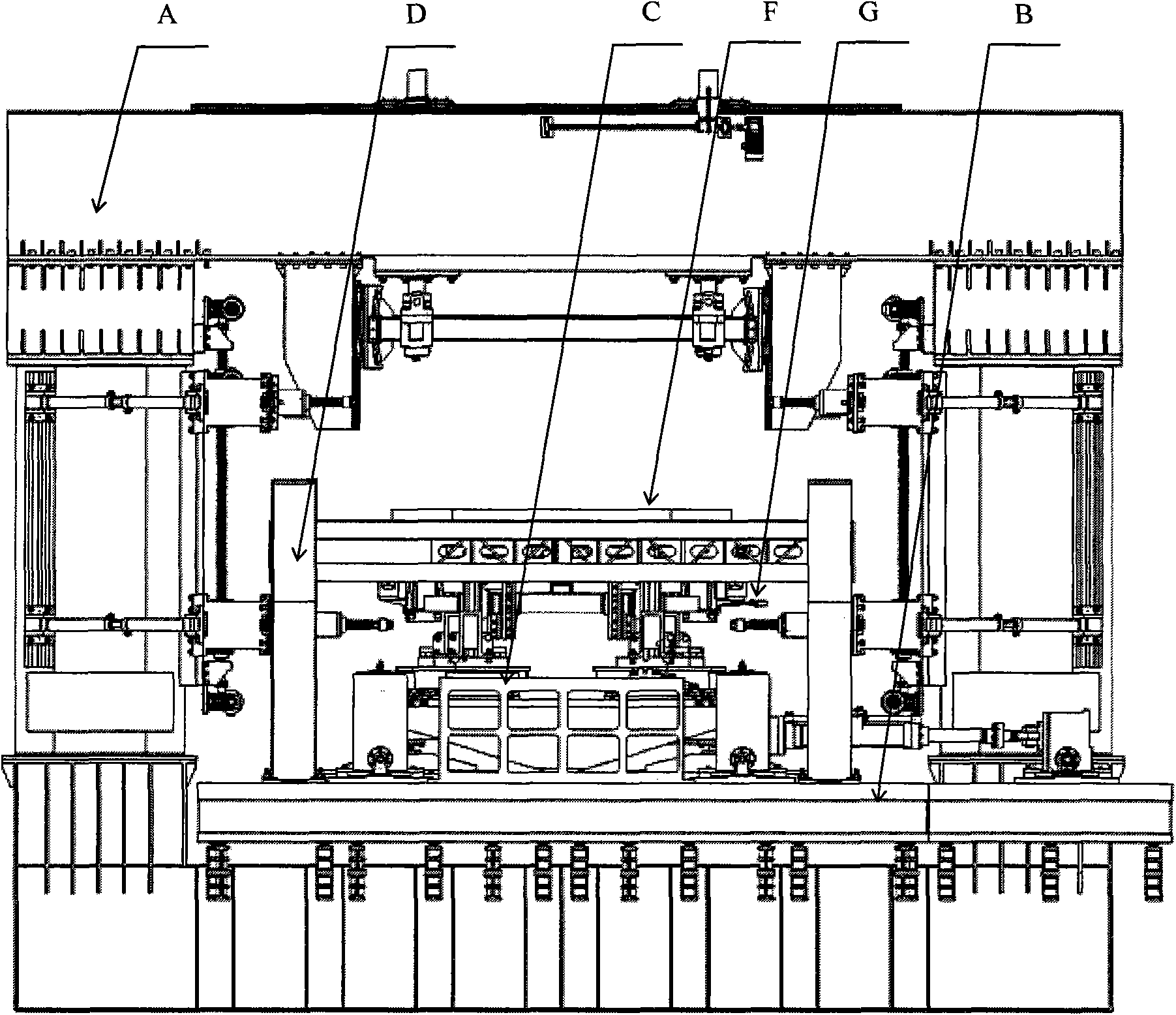

[0064] refer to figure 1 , 2 , 3, 4, 5, the closed-loop sprag-braced rail vehicle bogie stiffness parameter dynamic detection system is composed of a mechanical system, a testing system and a control system, wherein the mechanical system includes: a vehicle body longitudinal thrust seat assembly II, a Closed-loop diagonally braced rail vehicle bogie stiffness parameter dynamic testing platform III, two hoisted upper beam pillars V. Among them, the two hoisting upper beam pillars V are fixedly arranged on one side of the dynamic detection platform III for the stiffness parameters of the closed-loop slant-braced rail vehicle bogie, and the body longitudinal thrust seat assembly II is fixedly arranged on the rigidity parameter of the closed-loop slant-braced rail vehicle bogie. The front end of the parameter dynamic d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com