Method of preparing ZSM-5 molecular sieves

A ZSM-5, molecular sieve technology, applied in the direction of crystalline aluminosilicate zeolite, borocarbonane silicone crystalline aluminosilicate zeolite, etc., to achieve high synthesis yield, reduce production costs, and reduce the effect of viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

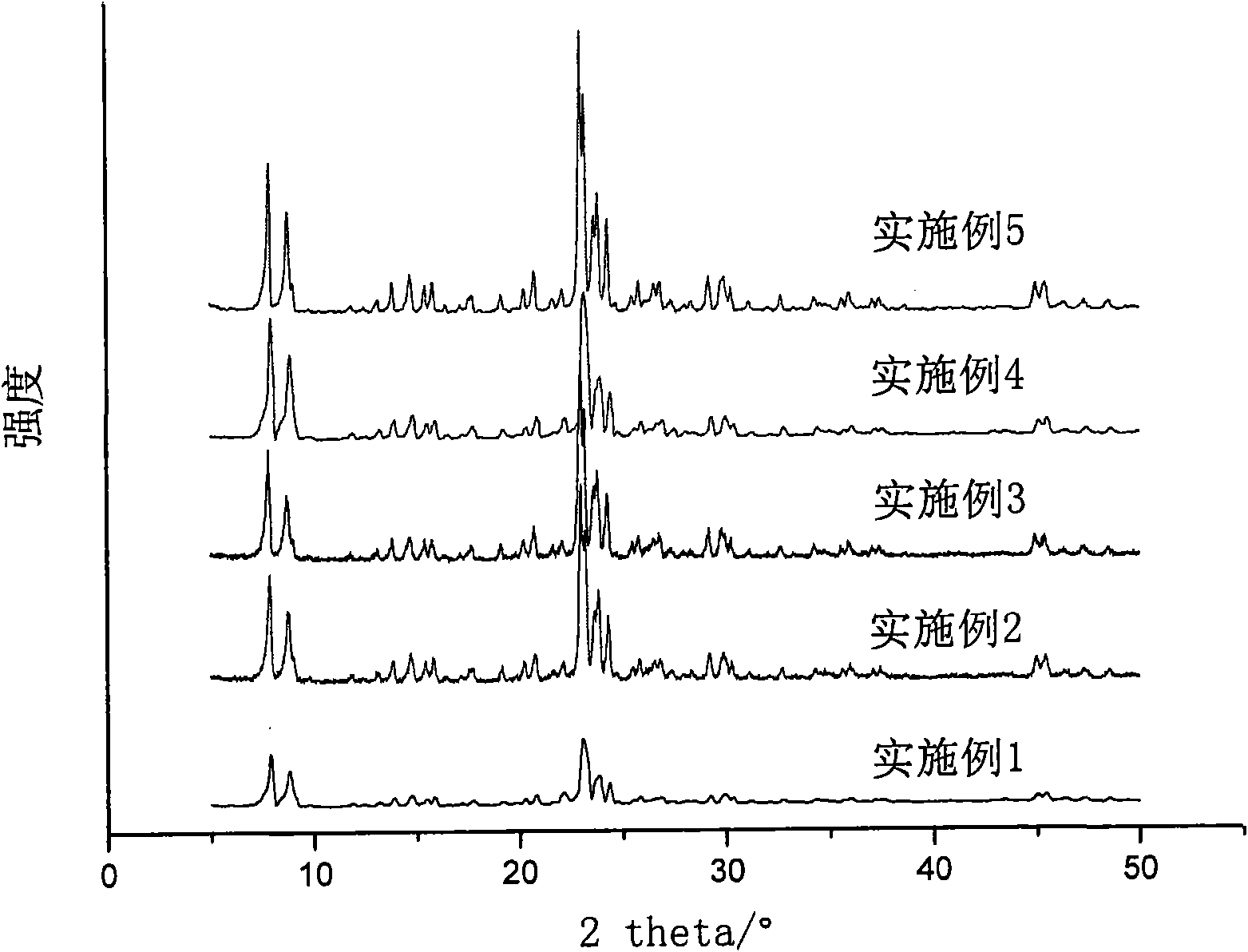

Embodiment 1

[0039] In a water bath at 60°C, the commercially available SiO 2 Content is 96.3wt% coarse porous silica gel 32.16g, water glass (containing SiO 2 27.25wt%, Na 2 O 8.75wt%) 202.17g and distilled water 107.32g, mixed and stirred for about 1 hour, then added aluminum sulfate solution, the aluminum sulfate solution is made with Al 2 o 3 15.1wt% Al 2 (SO 4 ) 3 18H 2 O 26.92g was obtained by adding 134.83g of distilled water. After stirring well, add 3M H 2 SO 4 Solution 40g, ZSM-5 seed crystal (synthesized in this laboratory, silicon-aluminum ratio 36) 10g, stirred for 40 minutes to prepare the mixture gel. The molar ratio of each component in the gel according to its oxide is: SiO 2 / Al 2 o 3 =36;Na 2 O / SiO 2 =0.12;H 2 O / SiO 2 =16. After sealing, heat up to 180°C and crystallize at a constant temperature for 24 hours under stirring. After the crystallization is completed, cool and filter to remove the mother liquor, wash and dry the filter cake to obtain a crys...

Embodiment 2

[0046] Under a water bath at 60°C, 39.94 g of coarse-porous silica gel, 203.47 g of water glass, and 101.34 g of distilled water were sequentially mixed together and stirred for 1 hour. Then add aluminum sulfate solution, the aluminum sulfate solution is made with Al 2 o 3 15.1wt% Al 2 (SO 4 ) 3 18H 2 O 23.53g was added to 141.73g of distilled water. After stirring well, add 3M H 2 SO 4 20 g of the solution, 10 g of ZSM-5 seed crystals (synthesized in our laboratory, with a silicon-aluminum ratio of 36), were stirred for 40 minutes to form a mixture gel. The molar ratio of each component in the gel according to its oxide is: SiO 2 / Al 2 o 3 = 45; Na 2 O / SiO 2 =0.15;H 2 O / SiO 2 =14. After sealing, heat up to 180°C and crystallize at a constant temperature for 24 hours under stirring. After the crystallization is completed, cool and filter to remove the mother liquor, wash and dry the filter cake to obtain a crystallized product.

[0047] According to X-ray diff...

Embodiment 3

[0050] At room temperature, 132.18 g of coarse-porous silica gel, 140.03 g of distilled water, and 154.45 g of 20 wt % NaOH solution were mixed together and stirred for 1 hour. Then add aluminum sulfate solution, the aluminum sulfate solution is made with Al 2 o 3 15.1wt% Al 2 (SO 4 ) 3 18H 2 O 40.04g was added into 114.41g of distilled water to dissolve the obtained. Then add 15g of ZSM-5 seed crystals (synthesized in our laboratory, with a silicon-aluminum ratio of 36), and stir for 40 minutes to form a mixture gel. The molar ratio of each component in the gel according to its oxide is: SiO 2 / Al 2 o 3 =36;Na 2 O / SiO 2 =0.18;H 2 O / SiO 2 =10. After sealing, heat up to 180°C and crystallize at a constant temperature for 24 hours under stirring. After the crystallization is completed, cool and filter to remove the mother liquor, wash and dry the filter cake to obtain a crystallized product.

[0051] According to X-ray diffraction (XRD), its phase belongs to ZSM-5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com