Tableware washing and drying machine

A technology for washing and drying tableware, which is applied to the washing machine/washing machine for tableware, the parts of the washing machine/rinsing machine for tableware, cleaning equipment, etc., can solve the problem of high temperature steam adhering to electrical parts and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

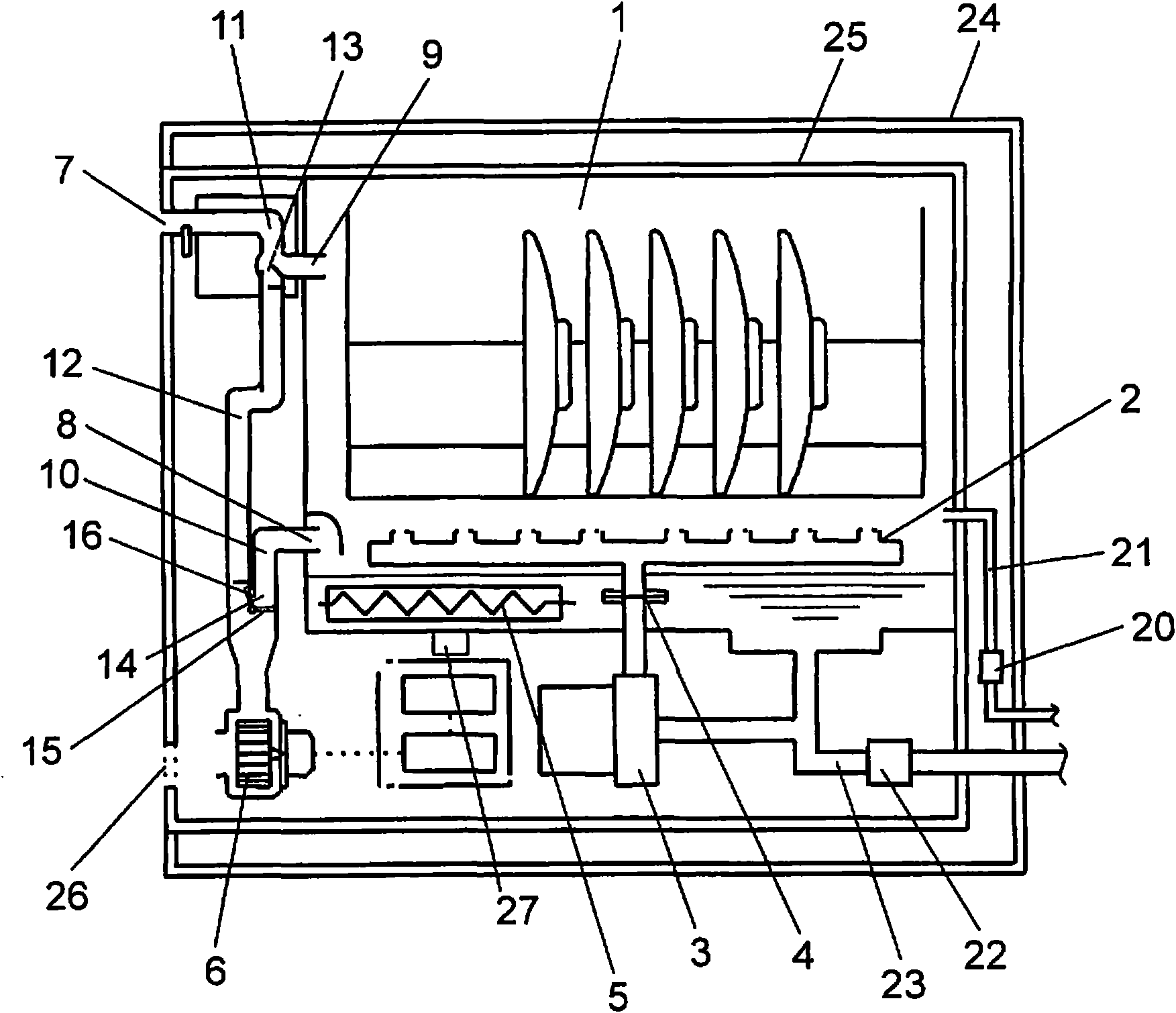

[0014] figure 1 It is a sectional view which shows the dish washer-dryer which concerns on embodiment of this invention. exist figure 1 Among them, the tableware washing and drying machine includes a housing 24 , a washing tank 1 , a heating device that is a heater 5 , an exhaust port 7 , an air blowing device that is a blower 6 , a second passage 11 , a third passage 12 , and an air volume distribution device 14 . A cleaning device 4 and a heater 5 are arranged at the bottom of the cleaning tank 1 . Here, the washing tank 1 is provided in the casing 24 so as to be freely drawn out in the front and rear directions via the sliding body 25, and is used to accommodate objects to be cleaned such as tableware. The cleaning device 4 includes a cleaning nozzle 2 for spraying cleaning water onto the object to be cleaned, and a cleaning pump 3 for pressurizing the cleaning water. The heater 5 is a heating device for heating the washing water to increase its temperature.

[0015] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com