Aluminum electrolytic cell current efficiency analyzer

A current efficiency, aluminum electrolytic cell technology, applied in the field of current efficiency measurement, can solve the problems of being susceptible to magnetic field interference, long measurement period of inventory method, increased gas humidity, etc., to achieve perfect real-time monitoring of current efficiency, remote maintenance and Debugging, Operation-friendly and Adjustable Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing, the present invention will be further described:

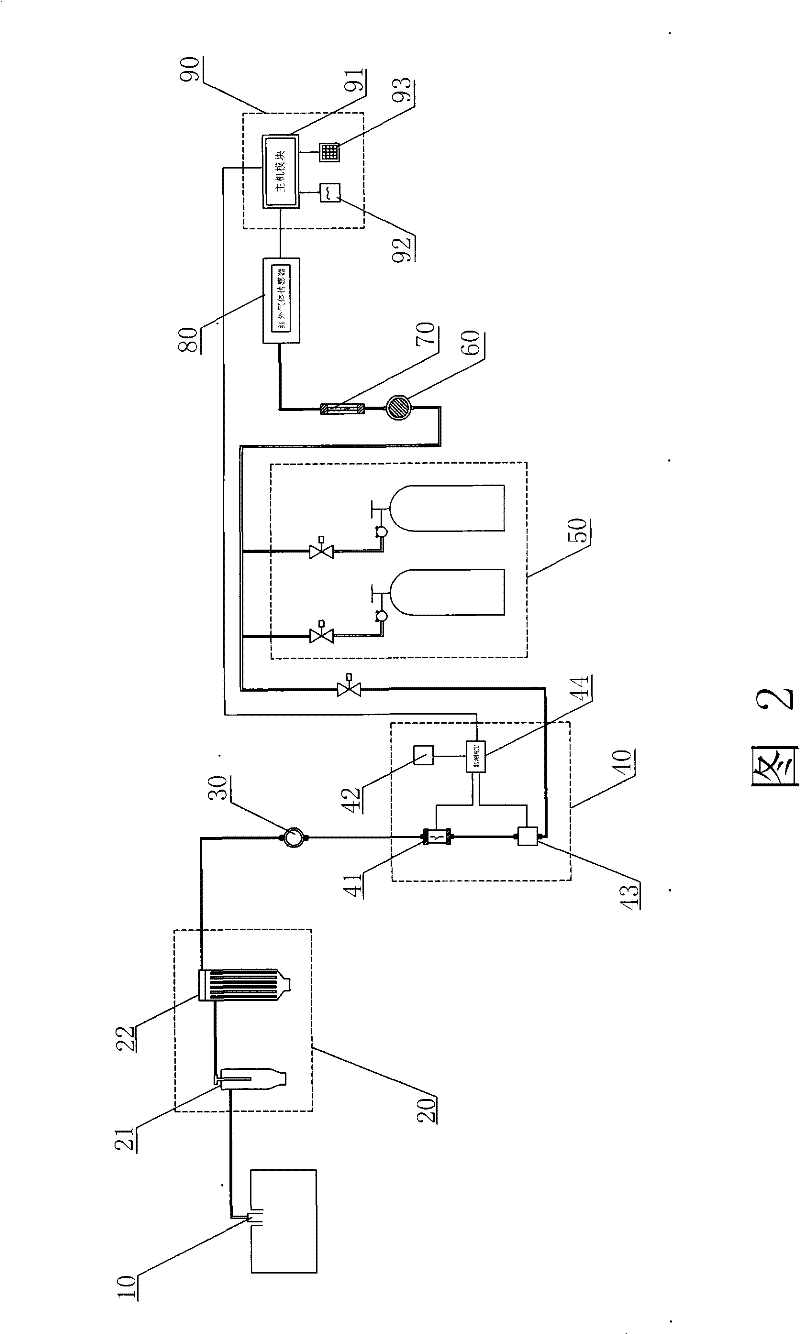

[0035] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6As shown: the aluminum electrolytic cell current efficiency analyzer is set in a closed case, including a gas sampling head 10, a gas pretreatment device 20, a vacuum pump 30, a gas monitoring device 40, and a high-precision membrane type connected in sequence through a gas pipeline. filter 60 , rotameter 70 , infrared gas sensor 80 and embedded computer 90 . Wherein the gas extraction head 10 is plugged in the fire hole of the electrolytic cell, the gas extraction head 10 transports the collected mixed gas to the gas pretreatment device 20; the gas pretreatment device 20 is composed of a cyclone dust collector 21 connected in sequence, a polymer filter The cyclone dust collector 21 is used to remove part of the moisture, electrolyte and other impurities contained in the gas taken out f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com