Construction method for resisting uplift in internal mold of concrete box

A technology for concrete and pouring concrete, which is applied in the fields of formwork/formwork/work frame, on-site preparation of building components, construction, etc. The effect of easy quality assurance, significant economic and social benefits, and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

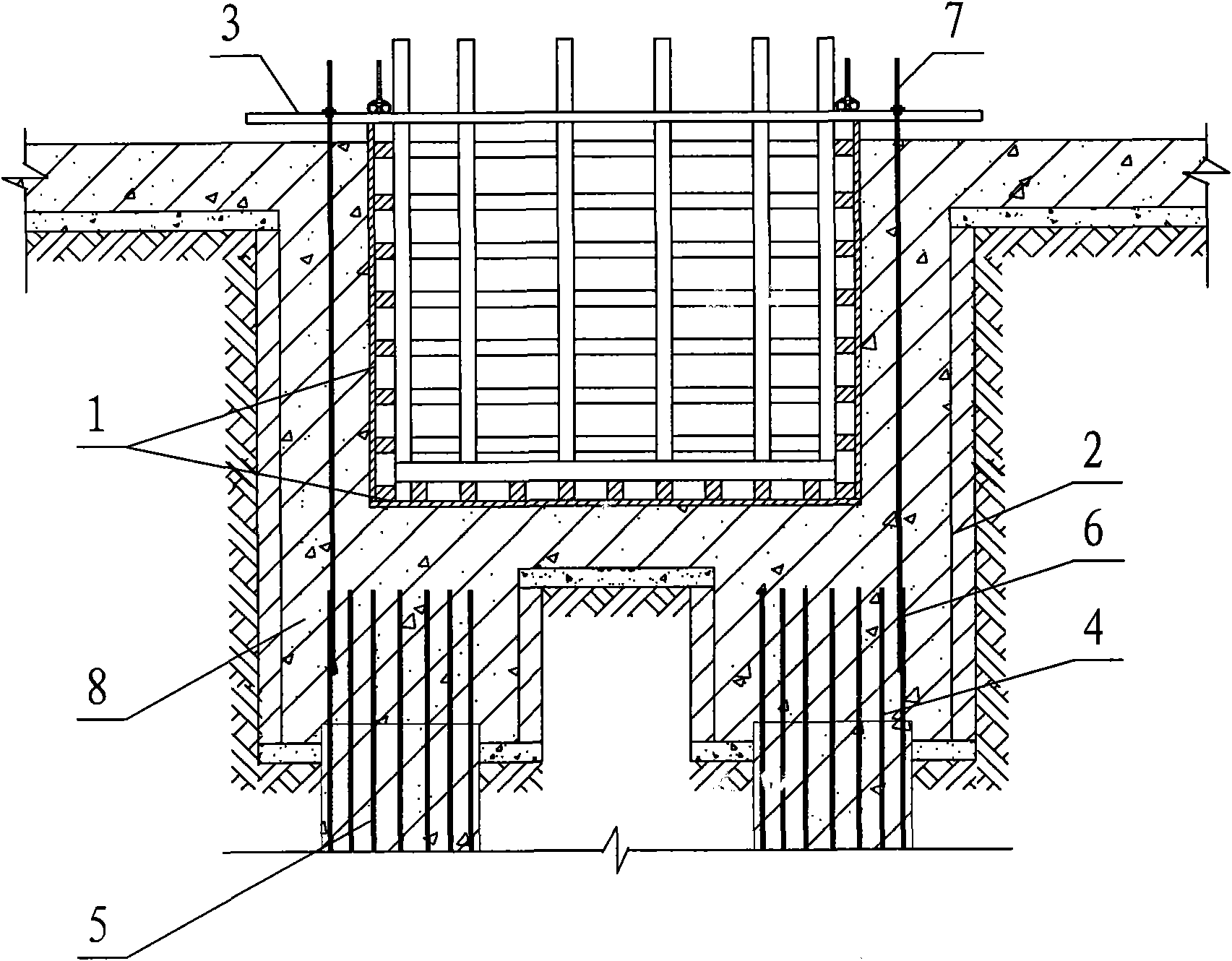

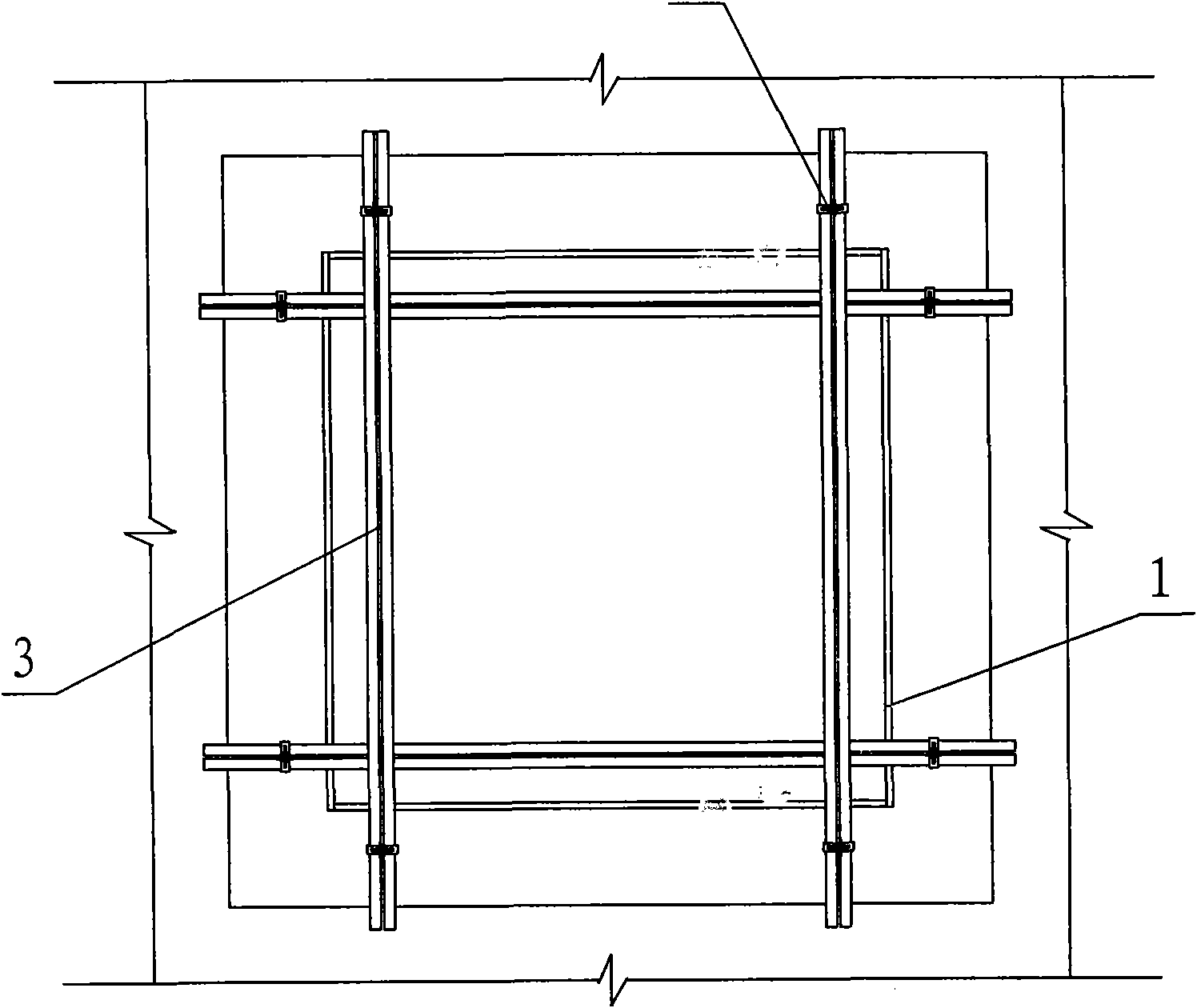

[0040] Adopt the inventive method building small-sized concrete box body, can carry out according to the following steps:

[0041]

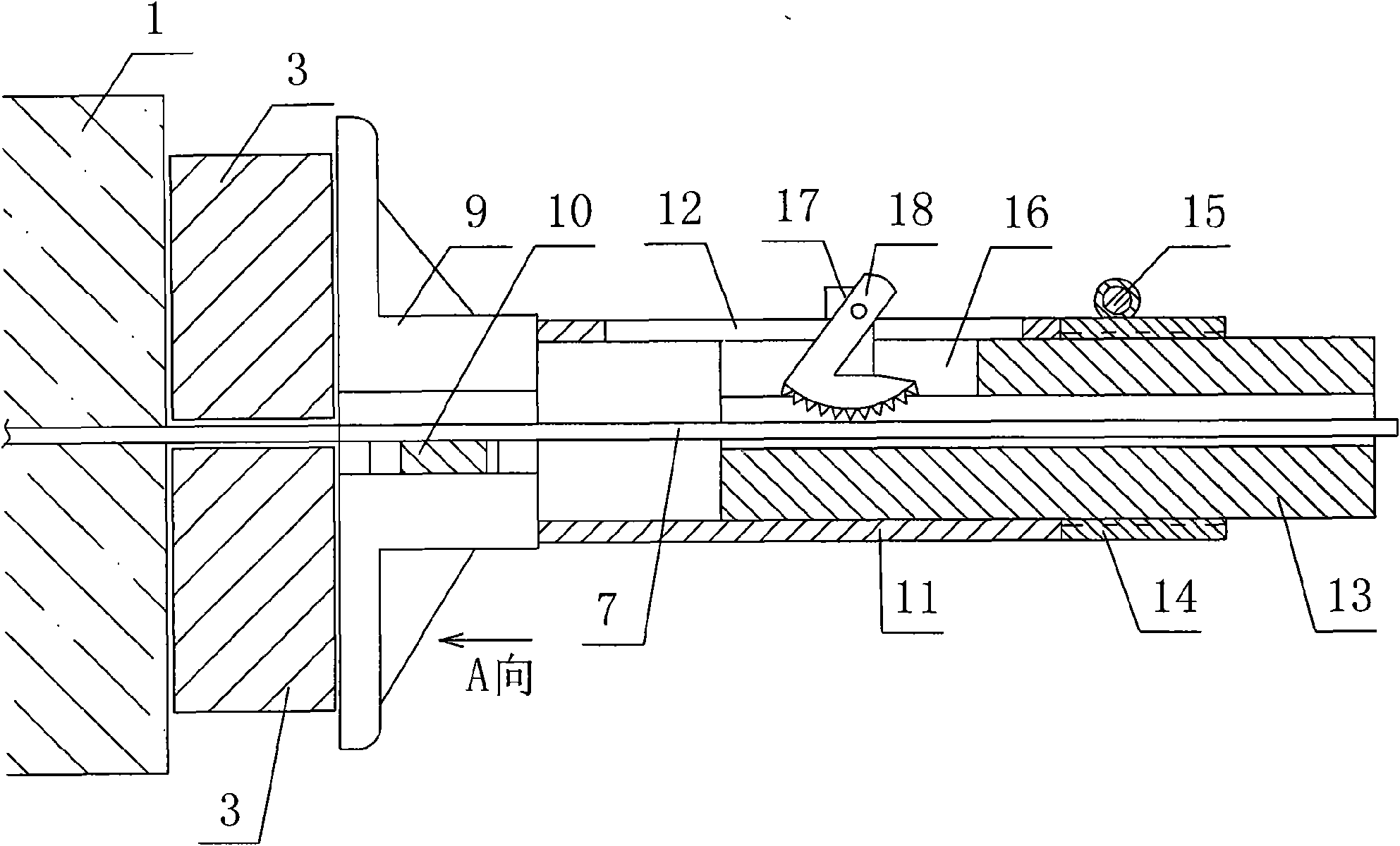

[0042] That is to say, for the foundation pit of the concrete box to be poured, the longitudinal reinforcement of the box wall of the concrete box is welded with the main reinforcement of the pile foundation at the bottom of the foundation pit; square or frame pipe; after tightening the longitudinal reinforcement of the box wall welded with the main reinforcement of the pile foundation, the upper end of the longitudinal reinforcement of the box wall is fixedly connected with the wooden square or frame pipe; The reaction force produced by the longitudinal steel bars on the wall and the frame tubes offsets the buoyancy of the concrete on the bottom plate of the box form, so that the wooden square or the frame tubes press the inner mold and prevent the inner mold from floating up.

[0043] In actual construction, it is best to carry out the follo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com