Controllable energy absorbing roll-over protective structure for engineering vehicle

A technology for engineering vehicles and protection devices, which is applied in the direction of earthmoving machines/shovels, construction, etc., and can solve the problems of death, injury to the driver, deformation of the cab, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

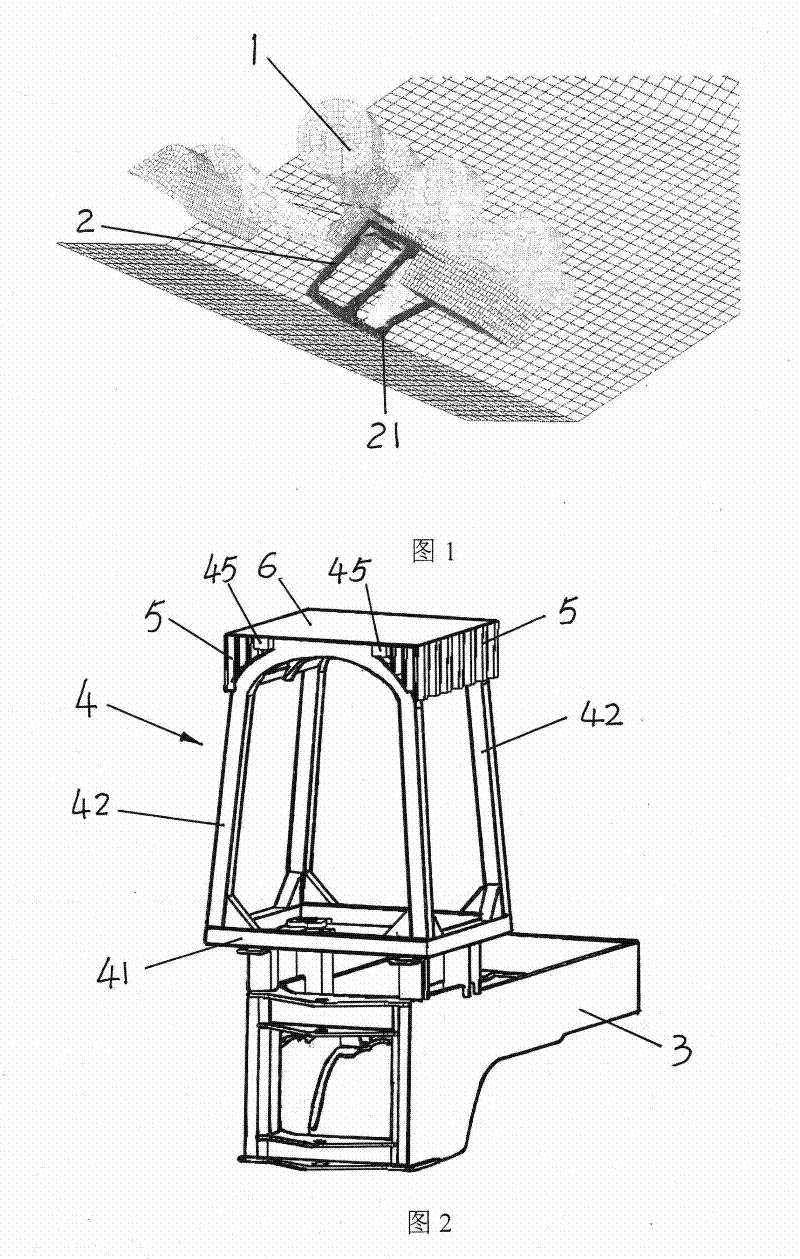

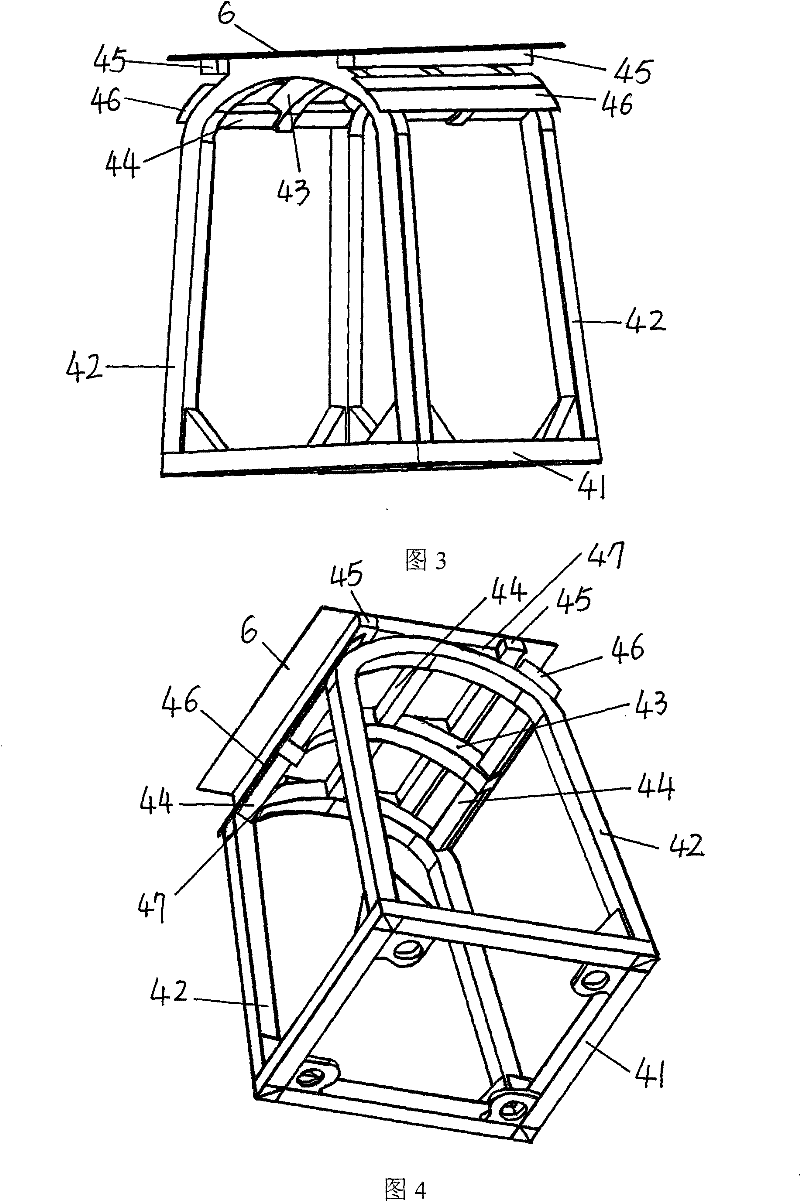

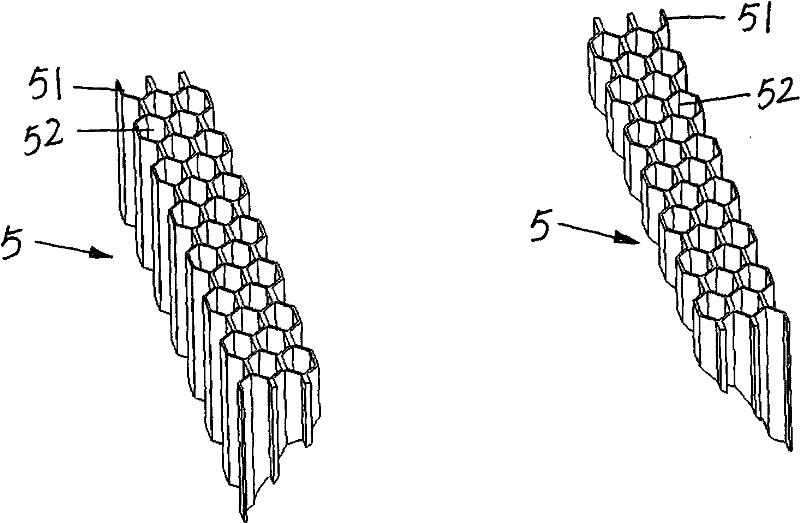

[0017] See also shown in Fig. 2, be an embodiment of the present invention, this embodiment is installed on the rear vehicle frame 3 of engineering vehicle, is made up of cab frame 4 and two energy-absorbing grids 5, as image 3 , shown in Fig. 4, cab frame 4 is made of base 41, two arched stands 42, an arched frame 43, three connecting beams 44, two stressed beams 45 and two fixed plates 46, two arched The stand 42 is fixed on the base 41 front and rear, an arch 43 is set between the top surfaces of the two arch stands 42, and three connecting beams 44 are left, middle and right distributed with the two arch stands 42 and an arch. The top surface of frame 43 is fixed together, and the left and right arc surfaces of two arched stands 42 and an arched frame 43 are fixed with wedge-shaped blocks 47, and two stressed beams 45 are positioned at the left and right sides of two arched stands 42 respectively. Both sides, and are fixed together with the outer surface of wedge-shaped b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com