Method for production of emulsion fuel and apparatus for production of the fuel

A technology of emulsified fuel and manufacturing method, which is applied in the direction of combustion method, chemical instrument and method, emulsification, etc., and can solve the problems of failure to achieve, lack of combustion stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Examples and comparative examples of the invention of the present application are described below.

[0053] First, 8 liters of water (tap water) was heated to 70°C, and the oxidation-reduction potential of the water was reduced to -114mv using a reduction device for bath water manufactured by Environmental Reduction Laboratory Co., Ltd.

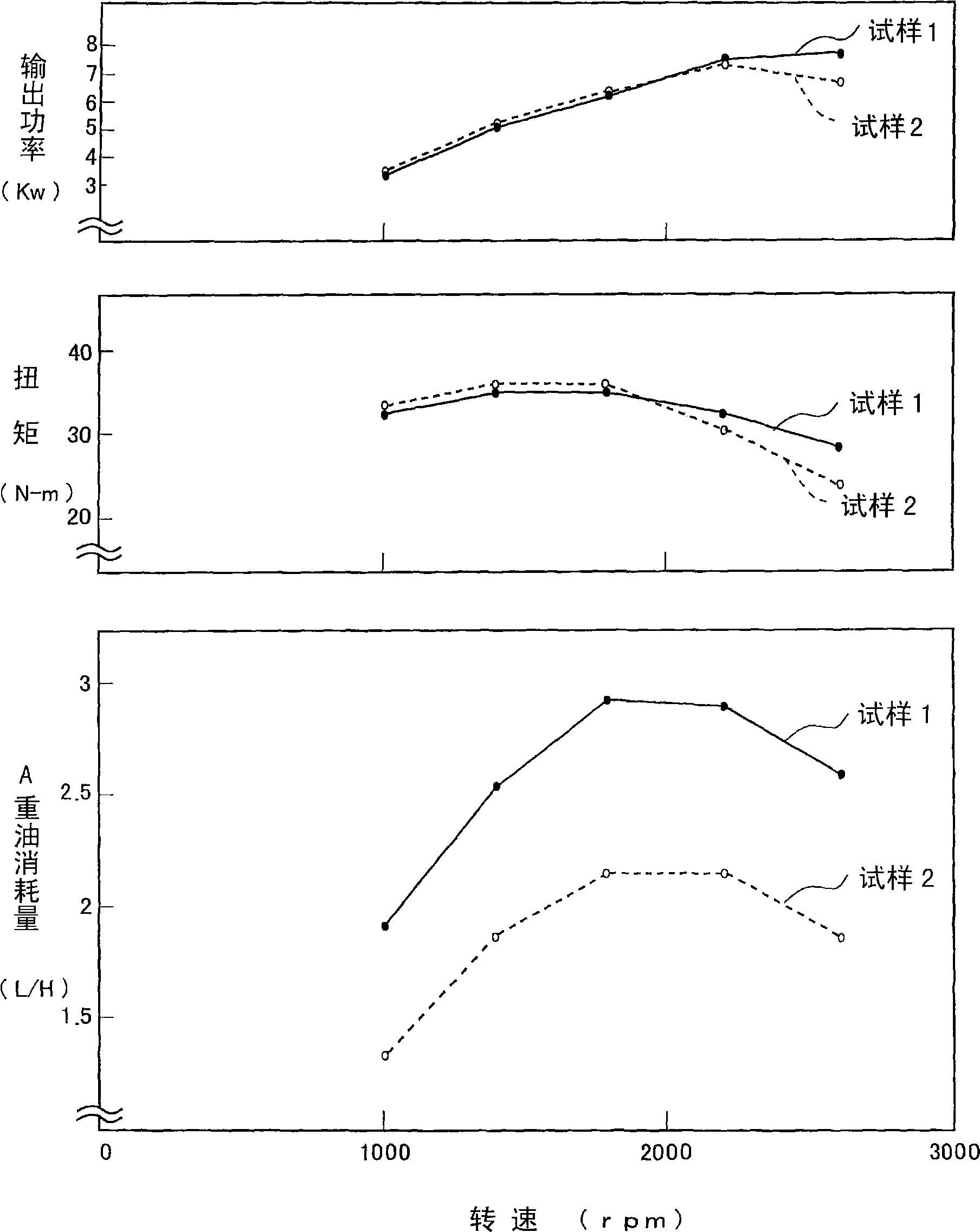

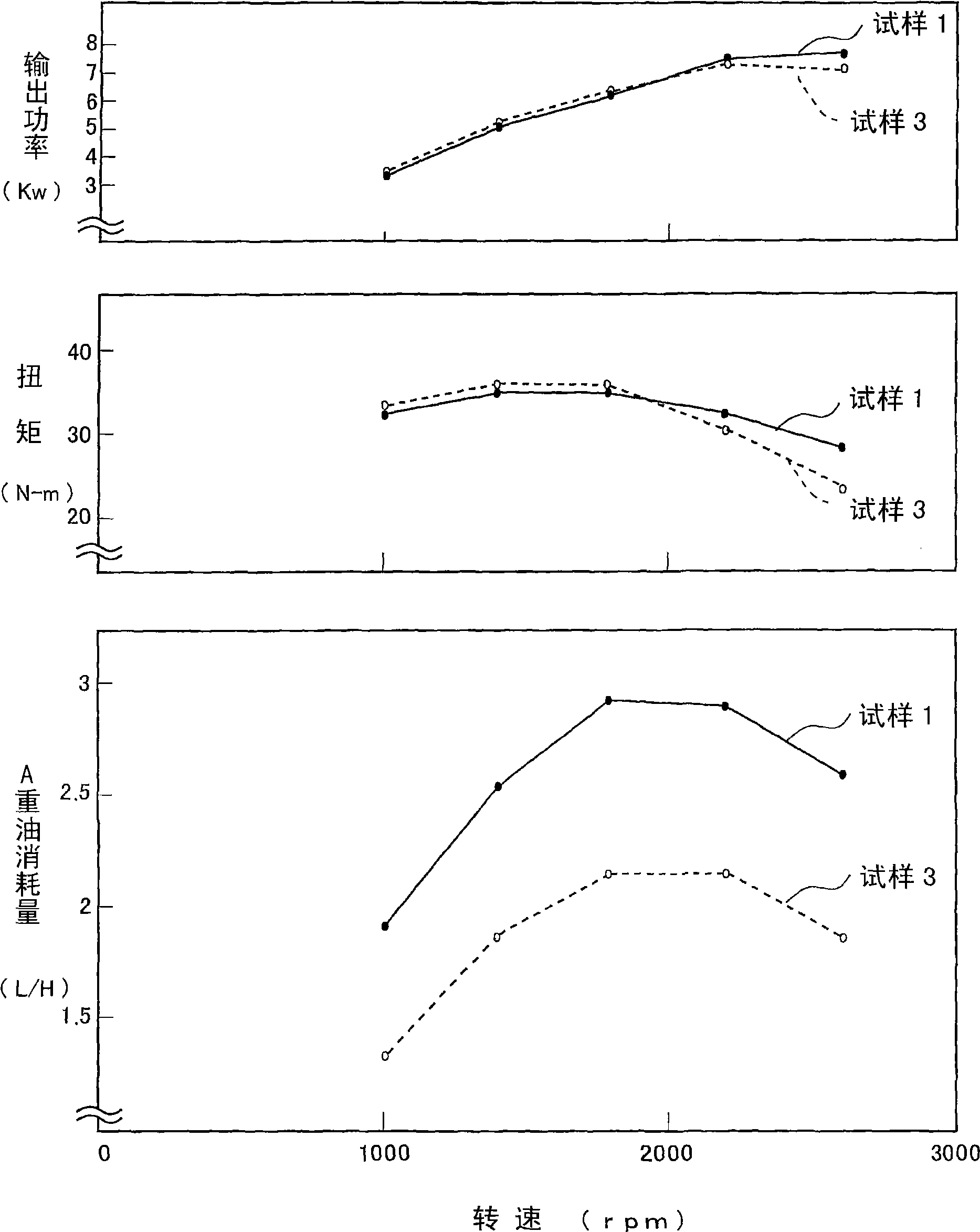

[0054] 5.88 liters of A-heavy oil and 160 cc of emulsifier were added to 1.96 liters of the reduced water, and after primary stirring by manual stirring, the mixture was finely divided and mixed by a Nanomizer at a pressure of 3 MP to produce the emulsified fuel of the present invention. Each of the obtained emulsified fuels was a W / O type emulsion, and the average particle diameter of water in the emulsion was 300 to 500 nm.

[0055] The obtained emulsified fuel of the present invention was used as sample 2, and the mixed solution prepared in the same manner as sample 2 was passed through a Nanomizer at a pressure of 8MP to obtain the...

Embodiment 2

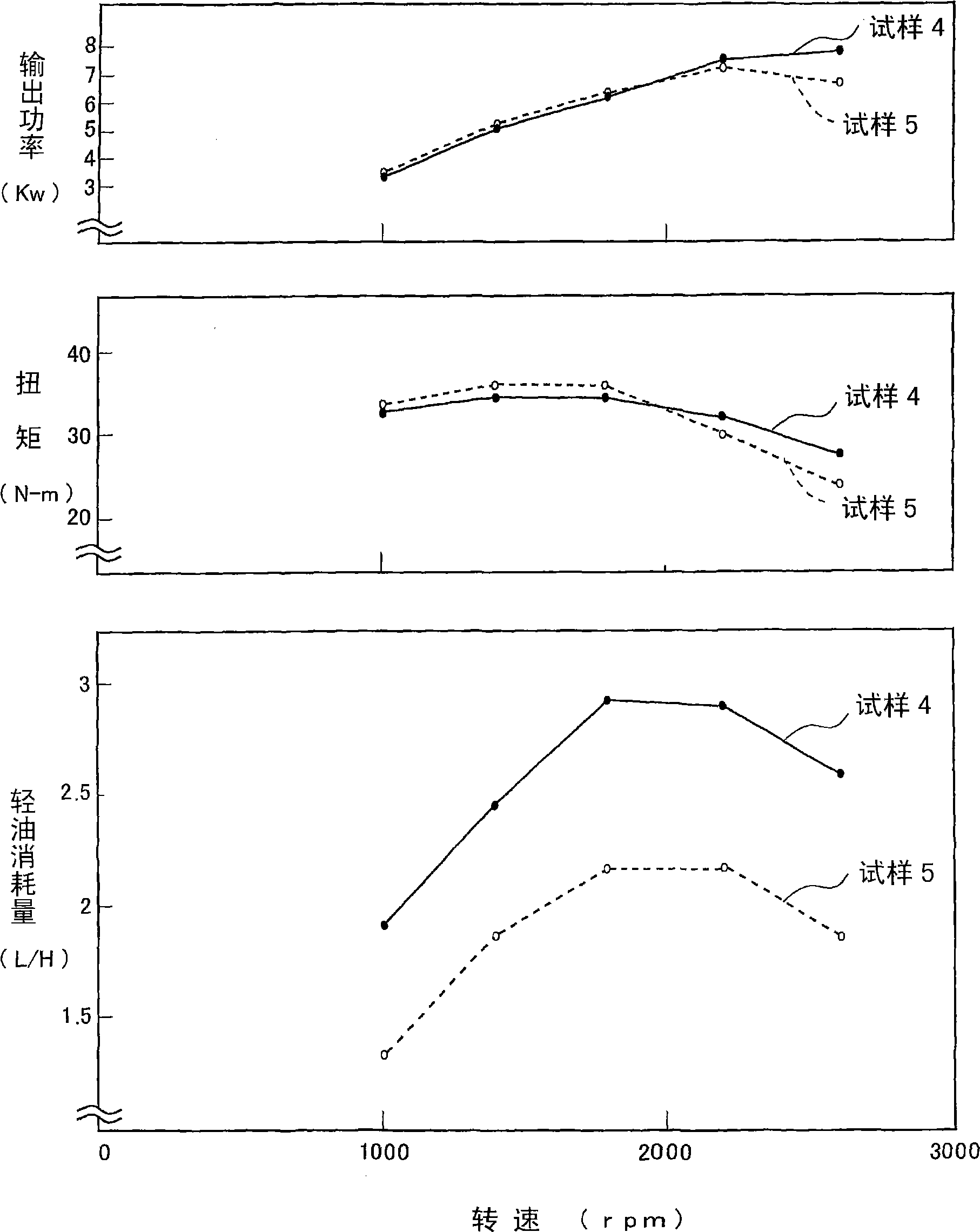

[0081] In this example, a diesel generator 13ES type manufactured by Denyo Co., Ltd. was used to continuously measure the concentration of nitrogen oxides and oxygen in the exhaust gas, and to measure the amount of power generated per unit of heavy oil, and to measure the Power generation efficiency of emulsified fuels.

[0082] As the emulsified fuel of the present invention, an emulsified fuel having a composition of 75% by weight of extra heavy oil, 24.7% by weight of water, and 0.3% by weight of an emulsifier was produced and used.

[0083] The emulsified fuel was prepared as follows: 2.50 liters of water and 0.04 liters of emulsifier were added to 8.33 liters of A-heavy oil (100 parts by volume of heavy oil: 29.7 parts by volume of water: 0.5 parts by volume of emulsifier), after primary stirring by manual stirring, at 3MP Micronization and mixing by Nanomizer unit under pressure. The average particle diameter of water in this emulsion fuel is about 300-500 nm.

[0084]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com