Moving contact component and startup relay

A technology of moving contacts and components, applied in the direction of relays, electromagnetic relays, detailed information of electromagnetic relays, etc., can solve the problems of reduced service life, affecting service life, high cost, etc., achieve stable working performance, reduce mechanical wear, and ensure service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (Embodiment 1, moving contact assembly)

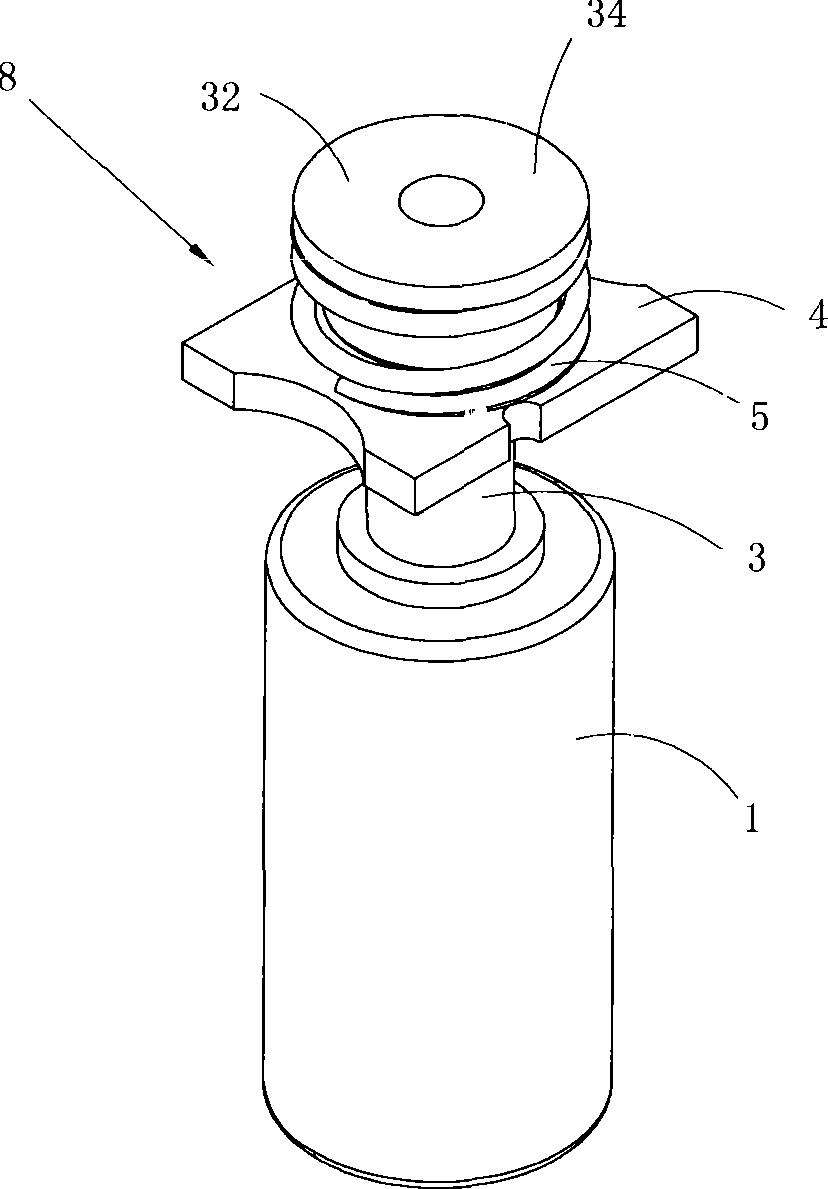

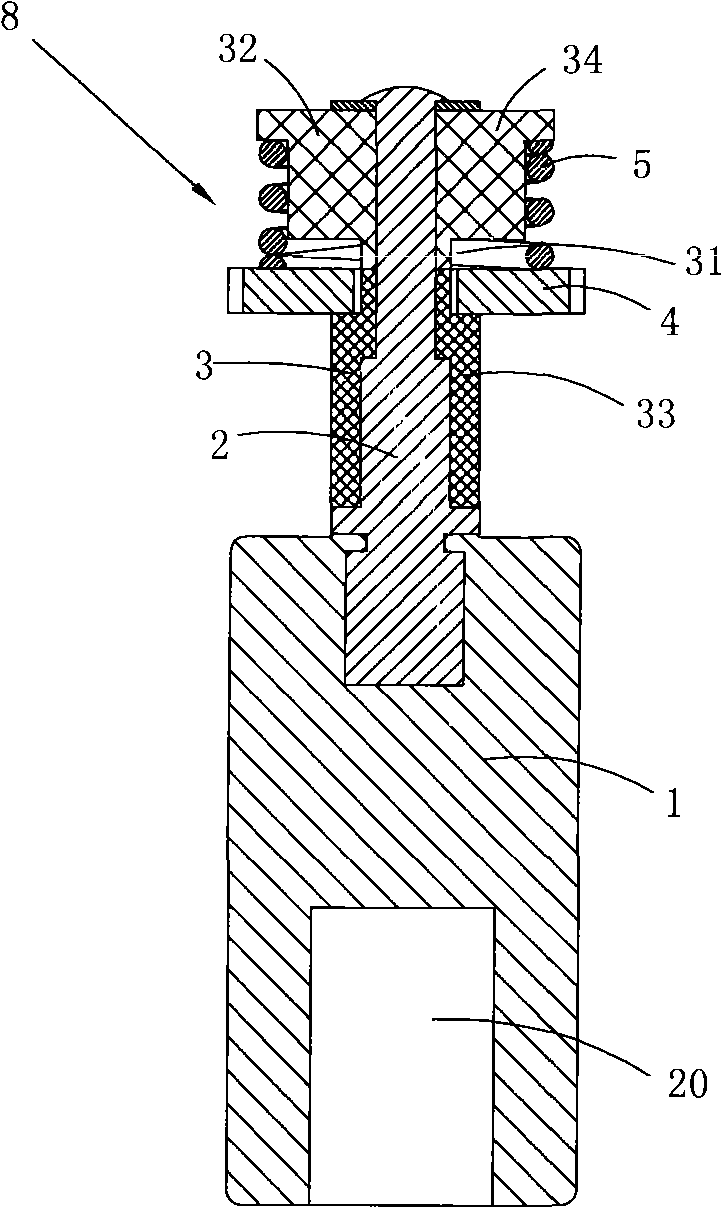

[0037] Figure 1 to Figure 3 A specific embodiment of the moving contact assembly of the present invention is shown, wherein figure 1 It is a schematic diagram of a three-dimensional structure of the moving contact assembly of the present invention, figure 2 yes figure 1 Schematic diagram of the half-section structure of the moving contact assembly shown; image 3 yes figure 1 A schematic diagram of the exploded structure of the moving contact assembly shown.

[0038] This embodiment is a moving contact assembly, see Figure 1 to Figure 3 , including a moving iron core 1, a positioning rod 2 fixedly connected to the moving iron core 1, an insulating sheath 3 sleeved on the positioning rod 2, a moving contact piece 4 sleeved on the insulating sheath 3, and a buffer Spring 5; the moving contact piece 4 and the buffer spring 5 are sequentially arranged along the direction away from the moving iron core 1; the insulating shea...

Embodiment 2

[0047] (Embodiment 2, start relay)

[0048] Figure 4 to Figure 11 A specific embodiment of the inventive starting relay is shown, wherein Figure 4 It is a schematic diagram of a three-dimensional structure of the starting relay of the present invention; Figure 5 yes Figure 4 The three-dimensional structural schematic diagram of the starting relay shown when viewed from another angle; Figure 6 yes Figure 4 The schematic diagram of the plane structure of the starting relay shown when viewed from a top view; Figure 7 yes Figure 6 Anatomical diagram along line A-A; Figure 8 yes Figure 6 Anatomical diagram along the B-B line; Figure 9 is Figure 4 A schematic diagram of a half-section structure of the start relay in the state when the coil is de-energized; Figure 10 yes Figure 4 A schematic diagram of the three-dimensional structure of the starting relay after the upper cover is removed; Figure 11 yes Figure 4 A three-dimensional structural schematic diagr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com