Cut tobacco elasticity on-line detection device and method thereof

A detection device and detection method technology, which is applied in the direction of measurement device, application of stable tension/pressure test material strength, instrument, etc., can solve the problem of not being able to meet production needs, and not being able to timely and accurately reflect the elastic value of cut tobacco and its changes, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0094] The technical solution of the present invention will be further described in more detail below in conjunction with the drawings and specific embodiments.

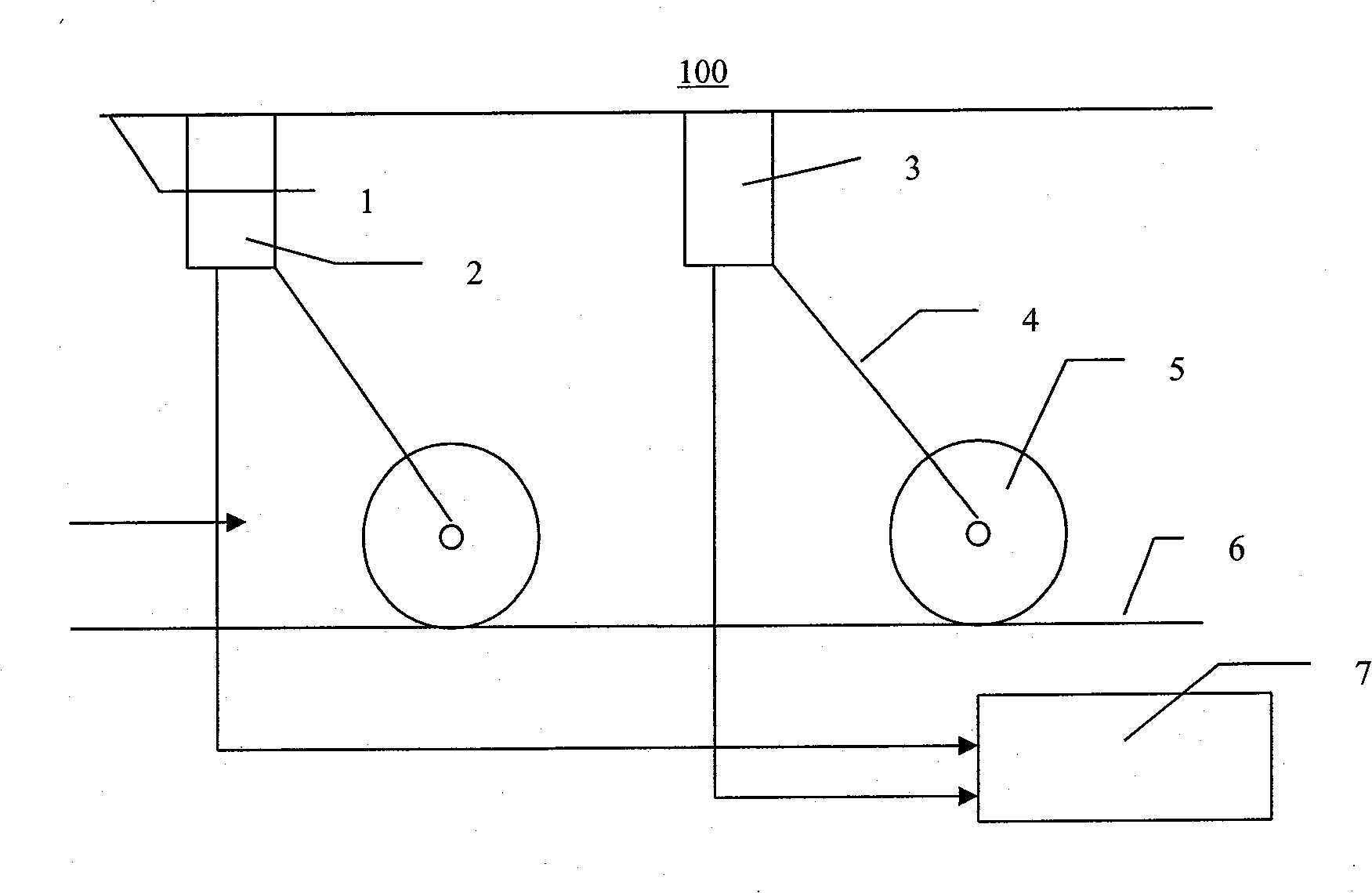

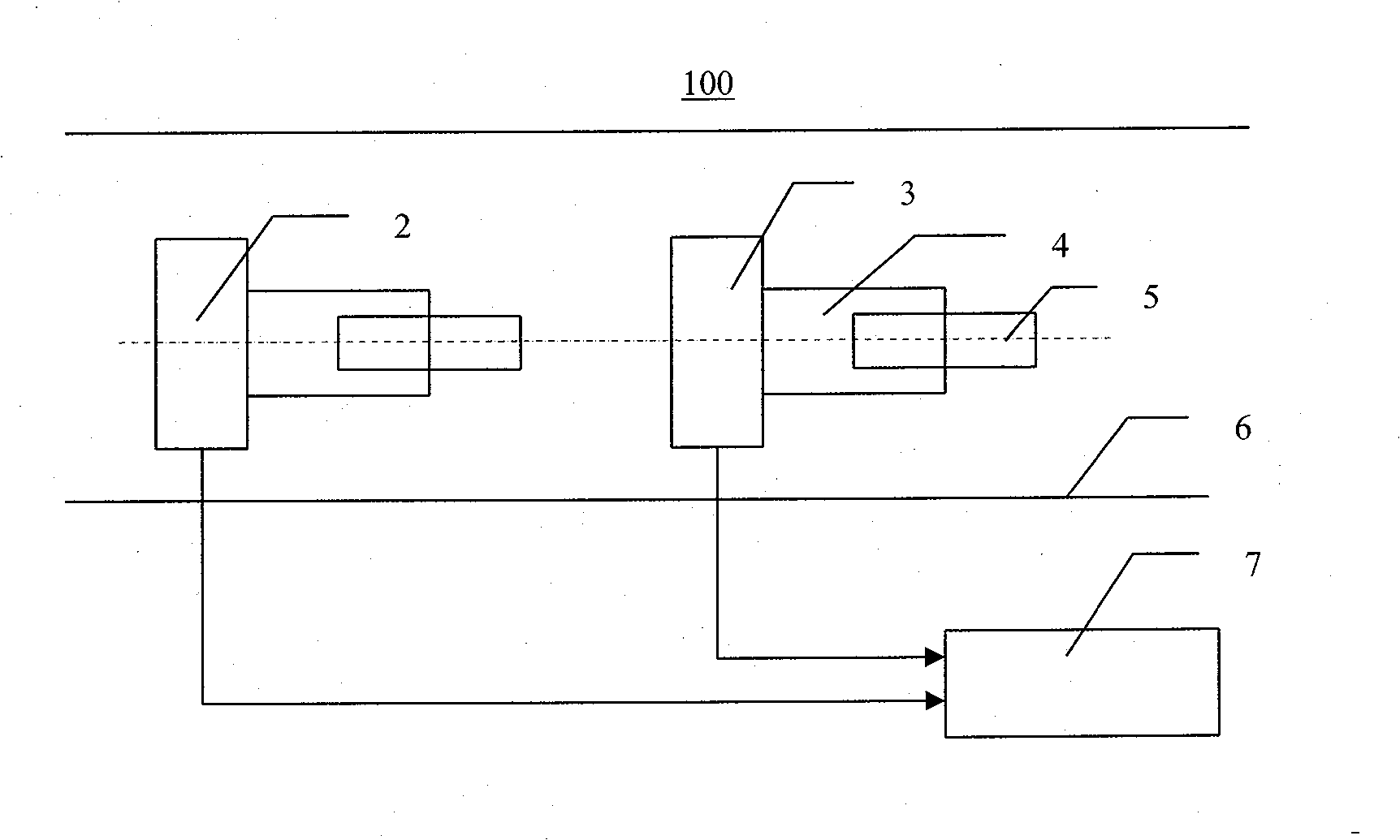

[0095] Such as Figure 1a Shown is the front view of the online detection device for the elasticity of shredded tobacco according to the present invention; Figure 1b It is a top view of the online detecting device for the elasticity of shredded tobacco of the present invention.

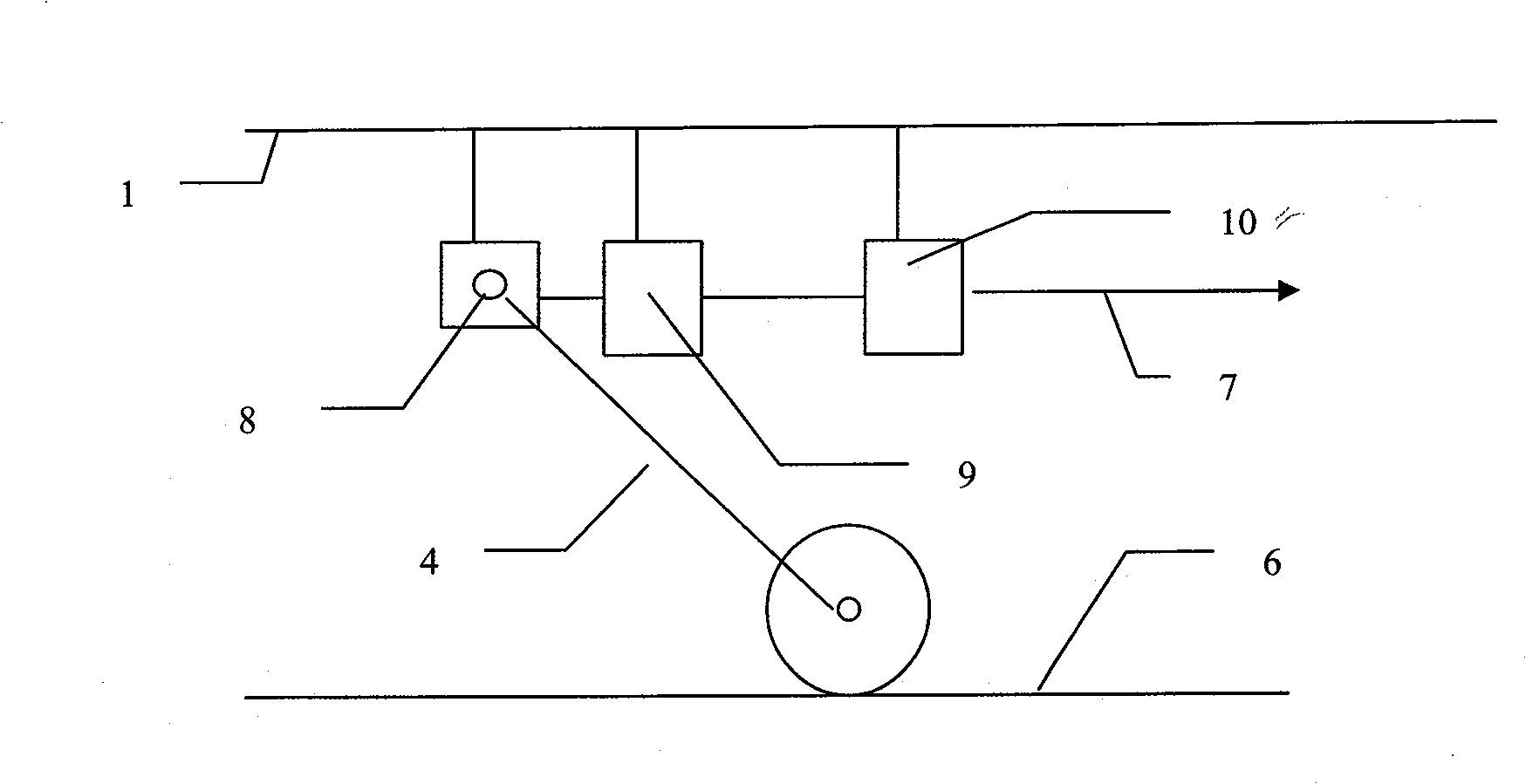

[0096] The detection device of the present invention adopts two pressing wheels, the first pressing wheel applies pressure to the cut tobacco to deform the cut tobacco, and the second pressing wheel detects the deformation of the cut tobacco after the pressure is released, so that the elasticity of the cut tobacco can be calculated. The present invention provides an online detection device 100 for the elasticity of cut tobacco, which includes a mounting bracket 1, at least two cut tobacco thickness measuring devices, a conveyor belt 6 and a dat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com