A method and device for removing sweet sorghum stalk leaves

A technology for sweet sorghum stalks and leaves, applied in the field of removing sweet sorghum stalks and leaves and its devices, can solve the problems of complex machine structure, low efficiency, and many faults, and achieve the effects of simple operation, high efficiency, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

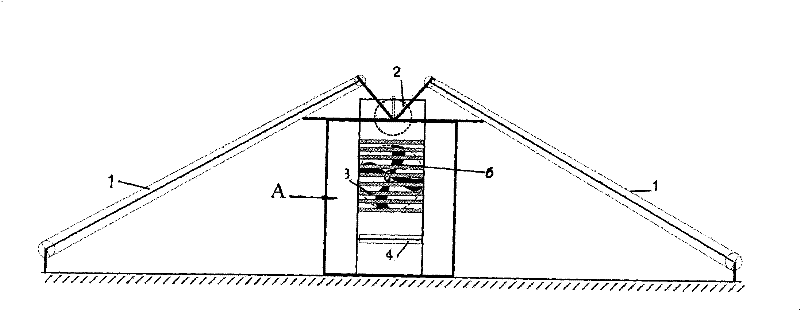

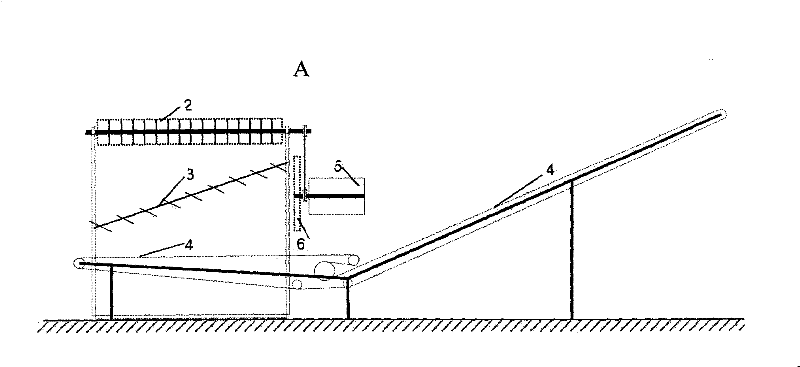

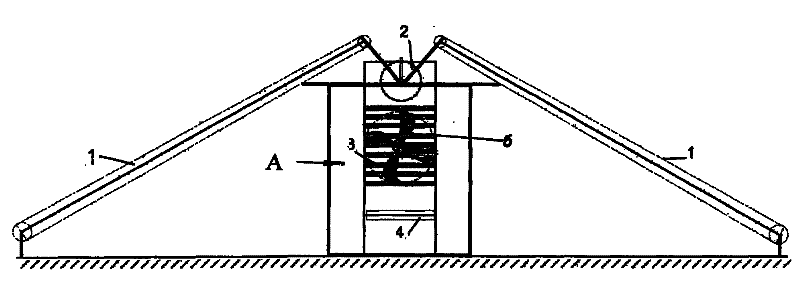

[0022] A method and device for removing leaves of sweet sorghum stalks, such as figure 1 , 2 As mentioned above, the efficient process for removing leaves of sweet sorghum stalks is that the whole bundle of sweet sorghum stalks has passed through the first process: conveying process, the second process: sawing process, and the third process: separation process of stem and leaf mixture 1. Stem-leaf mixture separation process, the fourth step: the stem transport process After a total of four processes, the finished stem is transported to the predetermined position.

[0023] The first conveying process: the sweet sorghum stalks are placed on the straw transmission belt 1 along and parallel to the direction of the sawing machine 2, and the whole bundle of sweet sorghum stalks on the straw transmission belt 1 is transported to the parallel setting by the straw transmission belt 1 Above the sawing machine 2 that is in a high position.

[0024] The second sawing process: the sweet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com