Segment-based ammonia flue gas desulfurization process and device thereof

A desulfurization process and a segmented technology, applied in the field of flue gas desulfurization, can solve the problems of large loss of absorbent ammonia, secondary pollution, unfavorable absorption reaction, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

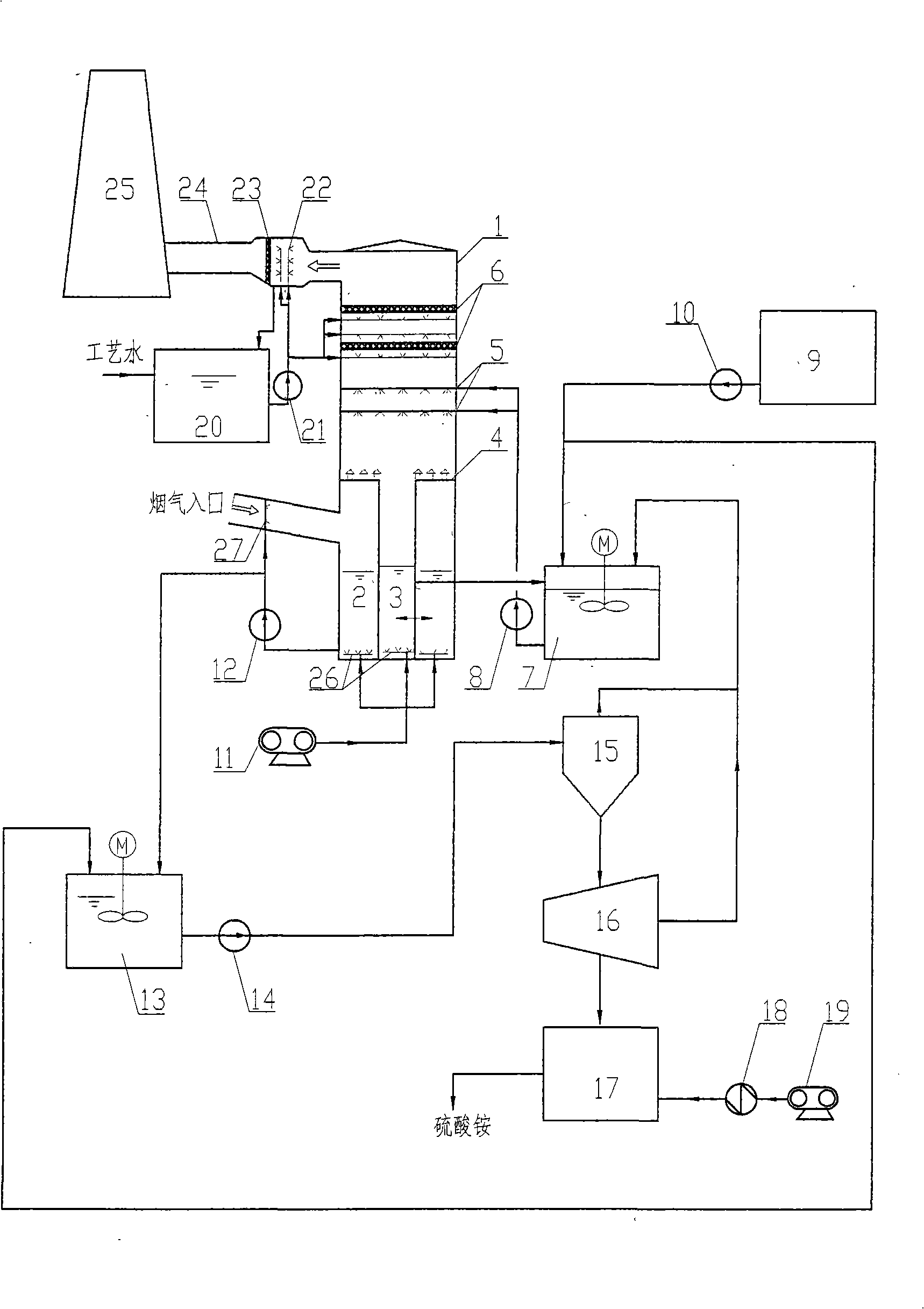

[0024] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0025] This process is used for flue gas desulfurization of the sintering head, and the waste ammonia water generated during the coking process of the coking plant is used as a desulfurizer to remove SO in the flue gas 2 . As shown in Figure 1, the high-temperature flue gas at 120-150°C after dedusting enters into the composite absorption tower (1), and a cooling spray device (27) is installed at the inlet flue to continuously spray ammonium sulfate solution to utilize the high-temperature flue gas. The heat of the gas is concentrated and crystallized, and the temperature of the flue gas drops to 60°C at the same time. The hot flue gas carries the evaporated liquid droplets of the crystallization tank (2) through the distribution plate (4) at the top of the absorption tower (1) and enters the absorption spraying section of the ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com