Method for removing moisture in gases by a Nafion tube

A moisture and gas technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problem that desiccant water removal cannot be used for corrosive gas analysis, water-soluble analyte loss, analyzer acid mist corrosion and other problems, to achieve the effect of good water removal performance, low cost and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

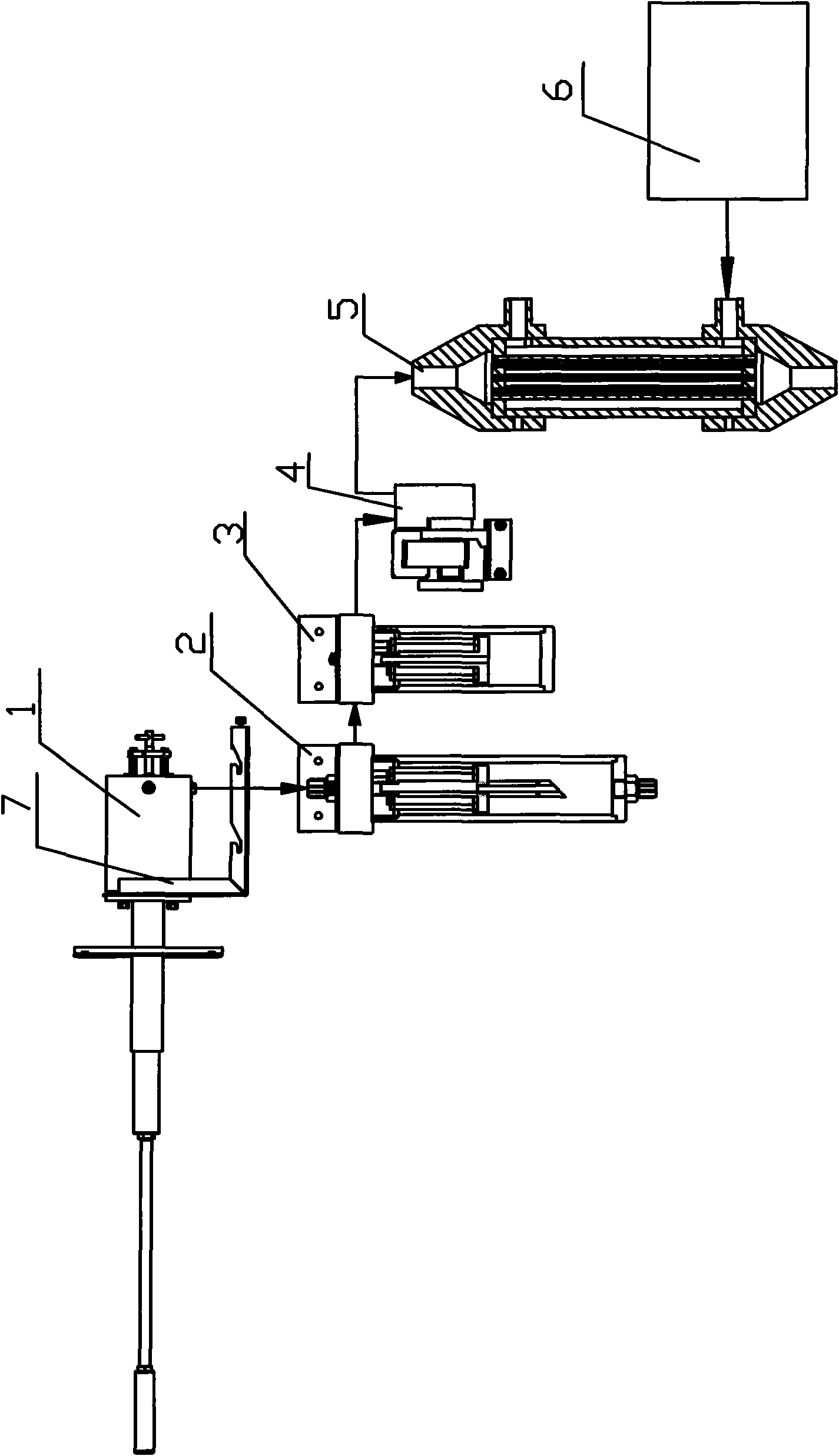

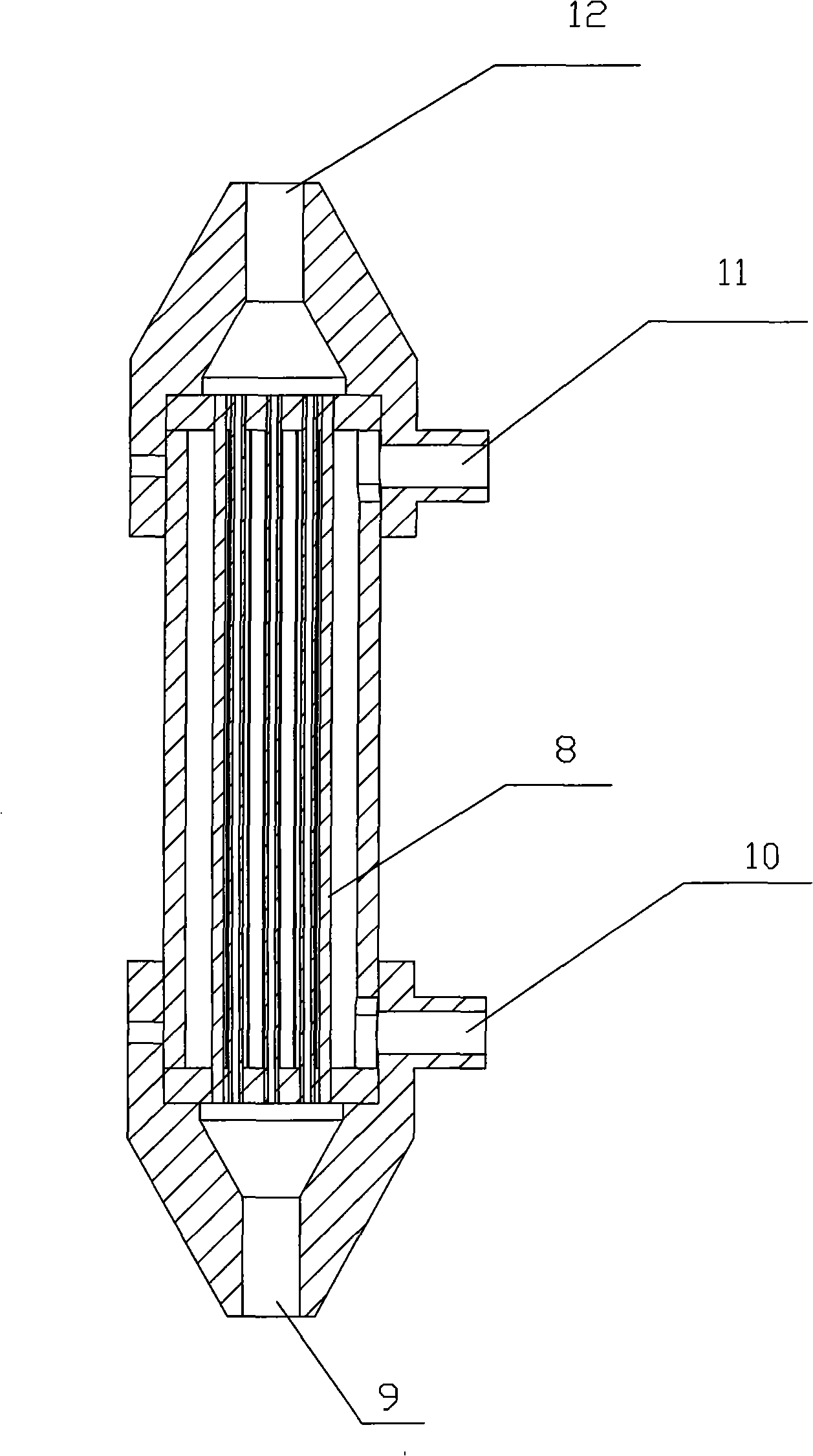

[0034] as attached figure 1 The experimental structure and attached figure 2 The structure of the dryer is shown, and the experimental system is composed of a humidifier, a gas sampler 1, an air pump 4, an instrument wind generator 6, an air compressor, a Nafion tube 8, a filter, and a dew point meter. The working process is: the humidifier humidifies the air around the gas sampler 1, measures the surrounding temperature, enters the gas sampler 1 and is heated by the heating part 7 in the gas sampler 1, measures the dew point temperature at the outlet of the gas sampler 1, and passes through 5um The microporous filter 2 and the 0.2um microporous filter 3 filter, and then the air pump 4 inputs the sample body into the flow meter to measure and limit the flow. The process gas is then heated to maintain the temperature of the sampler. Finally, the treated gas enters the dryer 5 consisting of Nafion tubes 8 . The 16L / min air produced by the air compressor passes through the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com