Printed board holding case, high frequency component, and method for producing the sames

A technology for printed substrates and manufacturing methods, applied in electrical components, mounting board safety devices, support structure installations, etc., can solve problems such as substrate shaking, substrate warping, and reduced quality and reliability of high-frequency components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

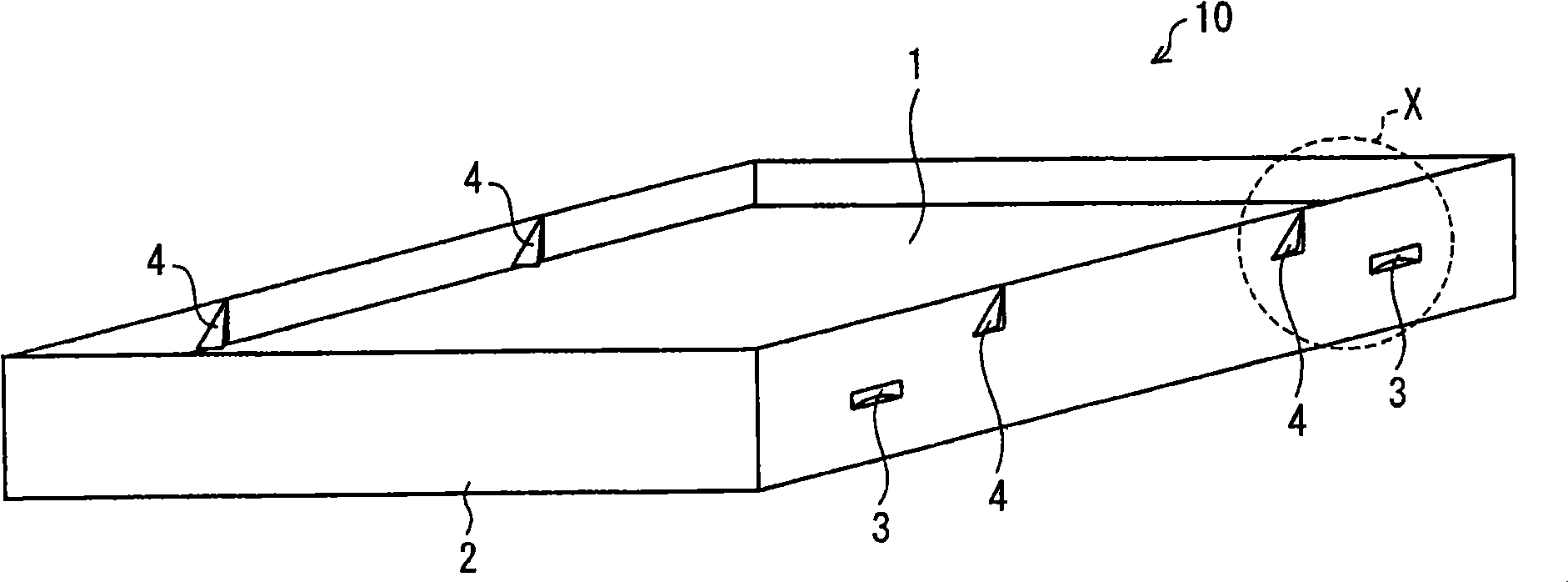

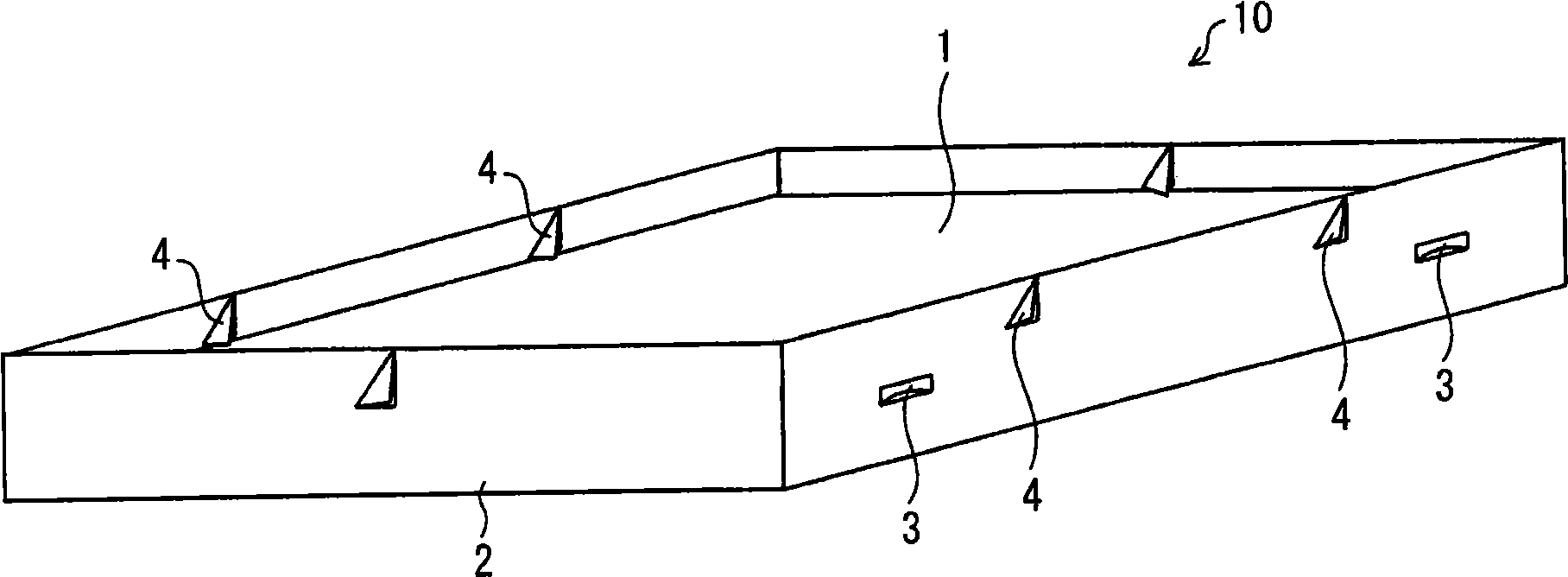

[0026] Below, refer to Figure 1 to Figure 9 One embodiment of this implementation will be described. In addition, in this embodiment, the high-frequency component 10 will be described. In the case (printed circuit board storage box) 2 of the high-frequency component 10, a substrate (printed circuit board) 1 is housed, and a high-frequency component is formed on the substrate 1. circuit, but the present invention is not limited thereto.

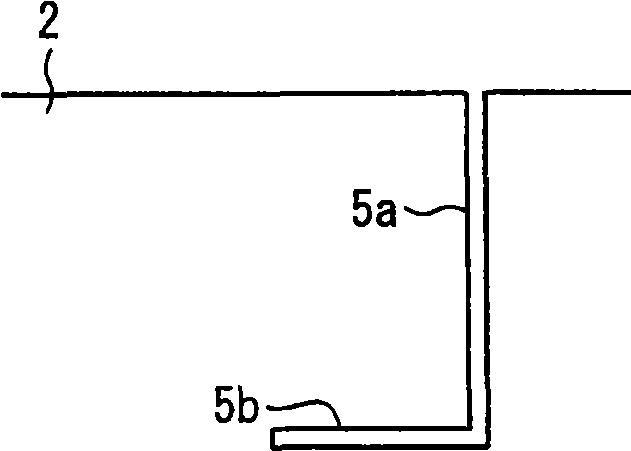

[0027] Refer to the following figure 1 The structure of the high-frequency component 10 will now be described. figure 1 It is a perspective view for explaining the high frequency component 10 which concerns on one Embodiment of this invention. Such as figure 1 As shown, the high-frequency component 10 includes a substrate 1 and a case 2 , and the substrate 1 is accommodated inside the case 2 . The box 2 is made of an elastic metal metal frame. In addition, the substrate 1 is stored from the opening side of the metal frame of the case...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com