Brush-throwing machine for removing protruding ink at two ends of conducting hole of printed circuit board and removing method thereof

A printed circuit board and via hole technology, which is applied in the secondary processing of printed circuits, the formation of electrical connection of printed components, and the cleaning/polishing of conductive patterns, etc. Problems such as ink protruding and leakage at both ends of the via hole, to achieve the effect of good use and promotion value, improve production efficiency, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

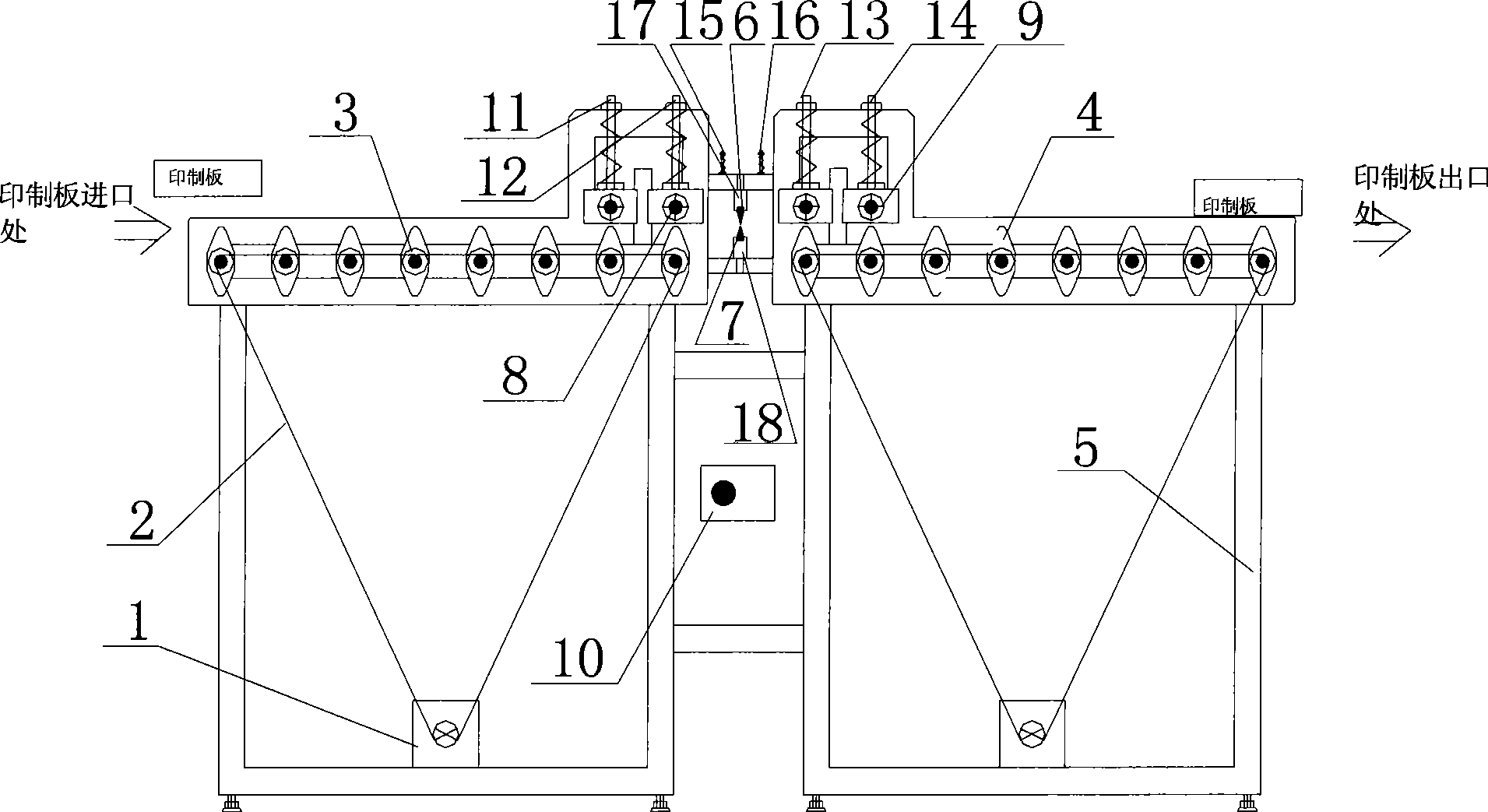

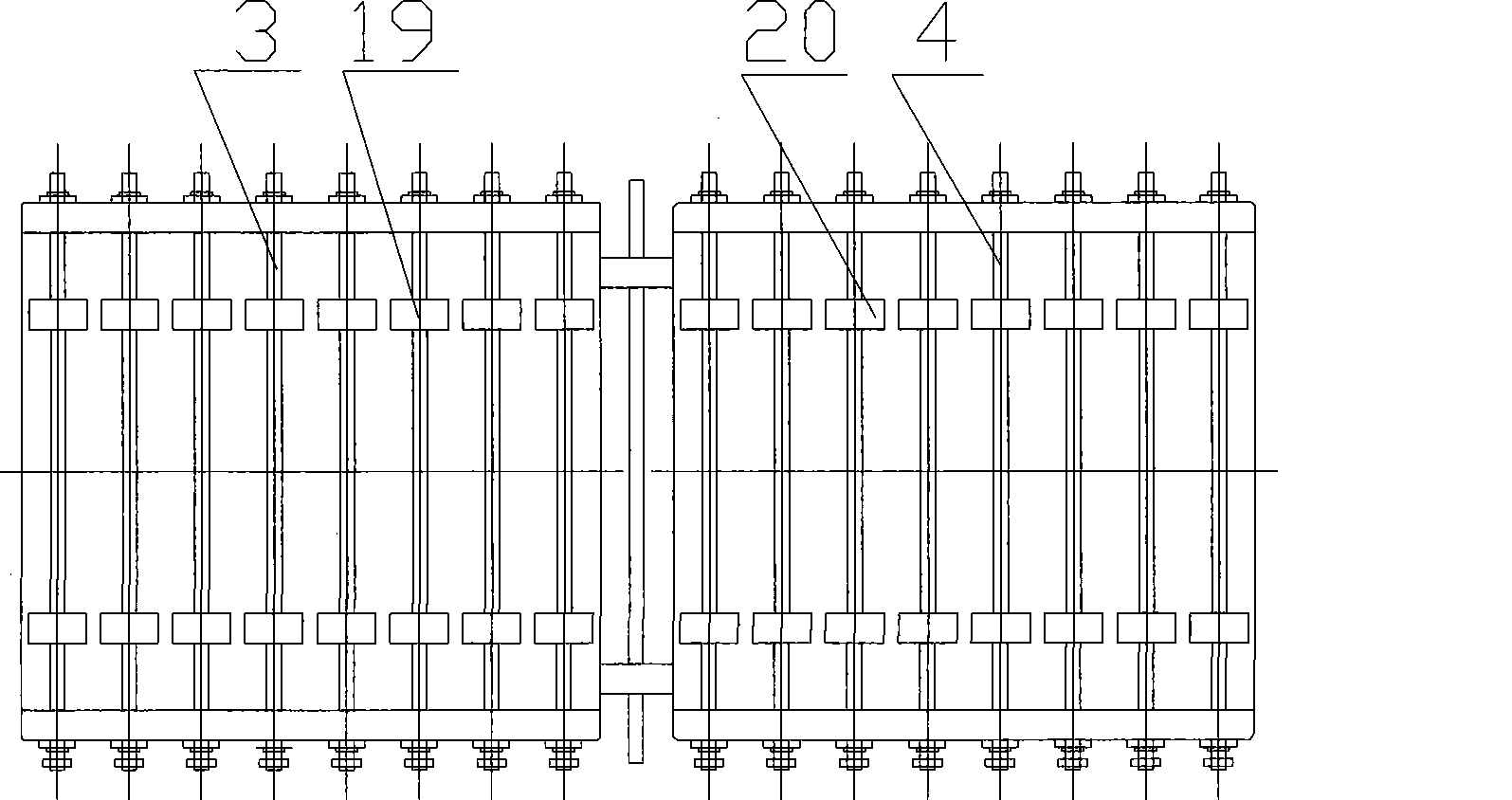

[0015] Embodiment 1: refer to figure 1 with 2 . The brush throwing machine used to remove the protruding ink at both ends of the through hole of the printed circuit board. The frame support body 5 is symmetrically distributed on the left and right. 5 constitutes the conveying roller table of the brush-throwing driving roller, and the conveying roller table of the brush-throwing driving roller located in the support body 5 of the left and right racks is driven by the motor 1 to rotate through the sprocket and chain 2 transmission mechanisms respectively; The rollers 3 and 4 are provided with adjustable spacing guide posts 19 and 20 . The two pressure roller adjustment mechanisms are respectively located on the brush-throwing drive roller conveying roller table, and the pressure rollers 8 and 9 in the adjustment mechanism are respectively spaced from the drive rollers 3 and 4 in the brush-throwing drive roller conveying roller table. They are spring-loaded adjustment mechanis...

Embodiment 2

[0016] Embodiment 2: On the basis of Embodiment 1, the method for removing the protruding ink at both ends of the through-hole of the printed circuit board, the brush-throwing drive roller conveying roller table on the brush-throwing machine is driven by the motor through the sprocket wheel and the chain transmission mechanism. And when the double-sided printed circuit board is transported to the relative gap formed by the upper and lower scraper blades of the polishing machine, the double-sided printed circuit board is forced to pass through the upper and lower scrapers under the action of the transmission roller table of the polishing transmission roller. At the moment of the blade, the scraper scrapes out the ink protruding from both ends of the via hole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com