Controller for a blade adjustment angle of at least one rotor blade of a wind power plant

一种调整角度、转子叶片的技术,应用在风力发动机的控制、风能发电、自动控制器等方向,能够解决控制器慢、电力和扭矩偏离不能被有效地修正等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

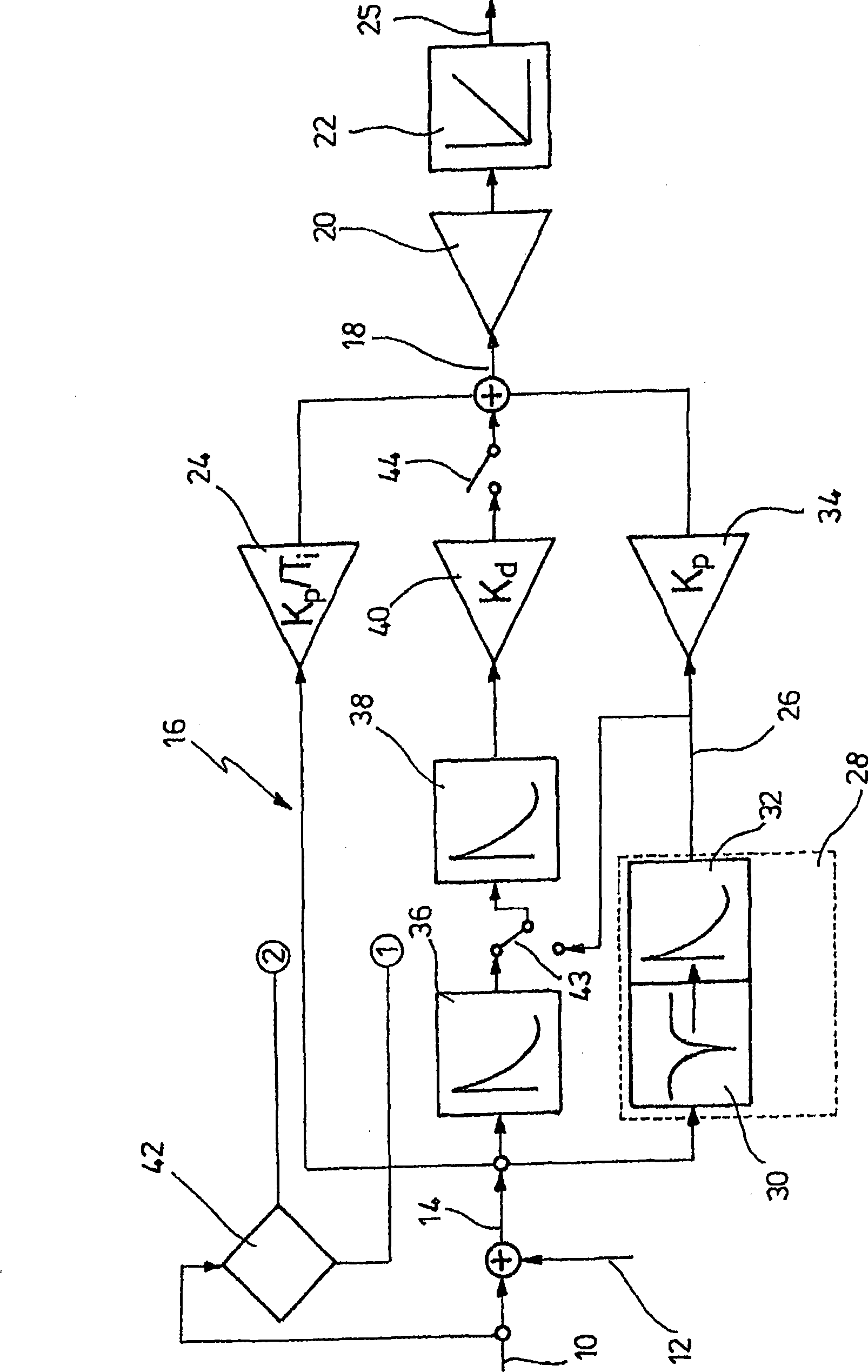

[0014] The figure shows a schematic view of the structure of the pitch controller to which the actual value 10 of the generator speed is supplied. The target value 12 of the generator speed is subtracted from the actual value of the generator speed to form an error variable 14 . This error variable 14 is supplied to a controller 16 . The signal at the controller output 18 is transformed via a proportional amplifier 20 and a characteristic field 22 into an output variable 25 of the blade adjustment angle. Adjustment of the blade adjustment angle takes place on the basis of the converted output variable 25 .

[0015] The controller 16 has an integrating means 24 which amplifies the signal in an integral manner irrespective of the operating state of the wind power plant. In the second controller branch 26 the supplied signal is filtered by a proportional filter 28 . The proportional filter 28 includes a bandstop filter 30 and a differentiating component 32 . The band stop fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com