Adjustable and progressive coil spring system for two wheeled vehicles

一种螺旋弹簧、软弹簧的技术,应用在自行车和摩托车悬架系统领域,能够解决没有公开装置如何工作等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

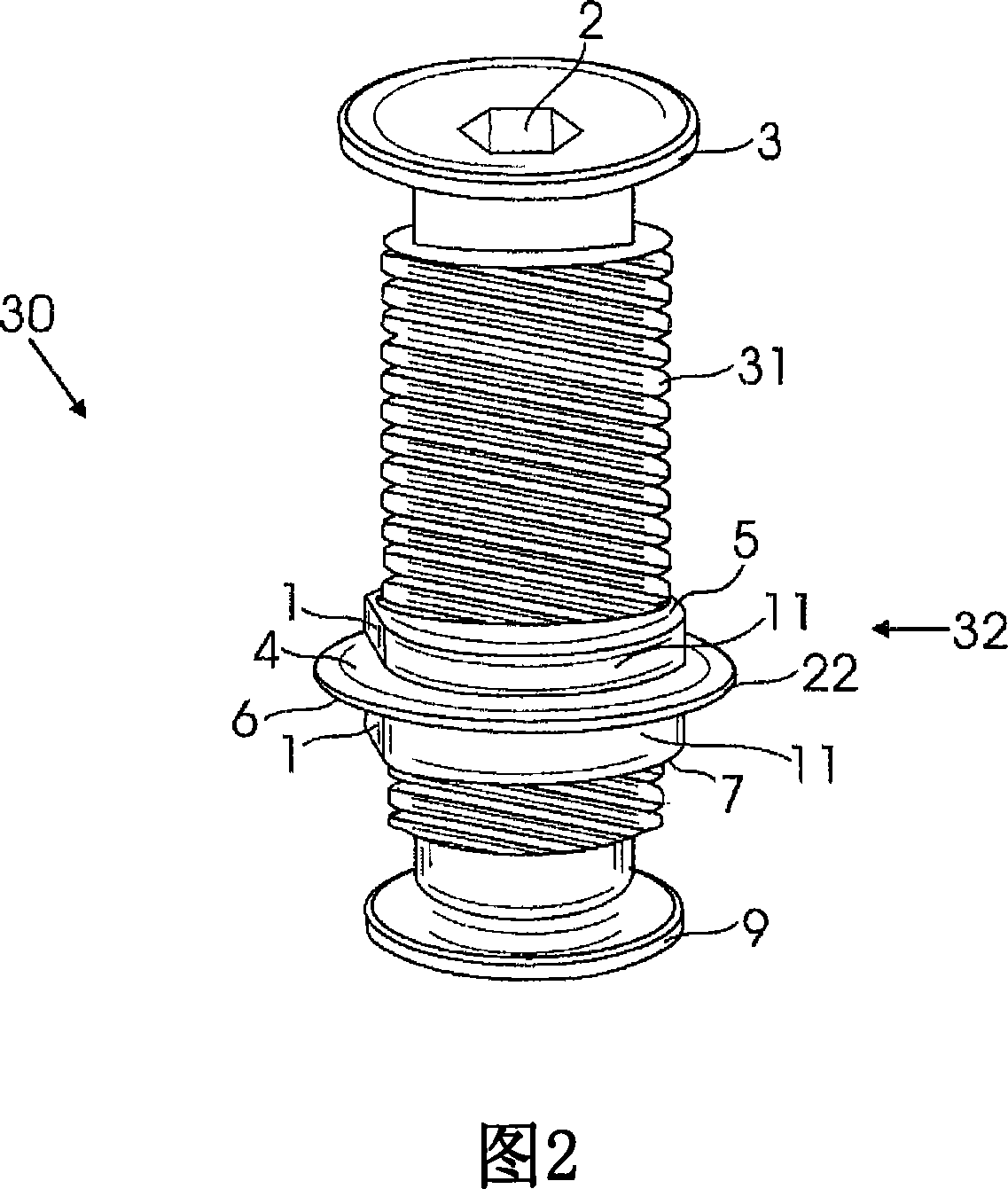

Embodiment Construction

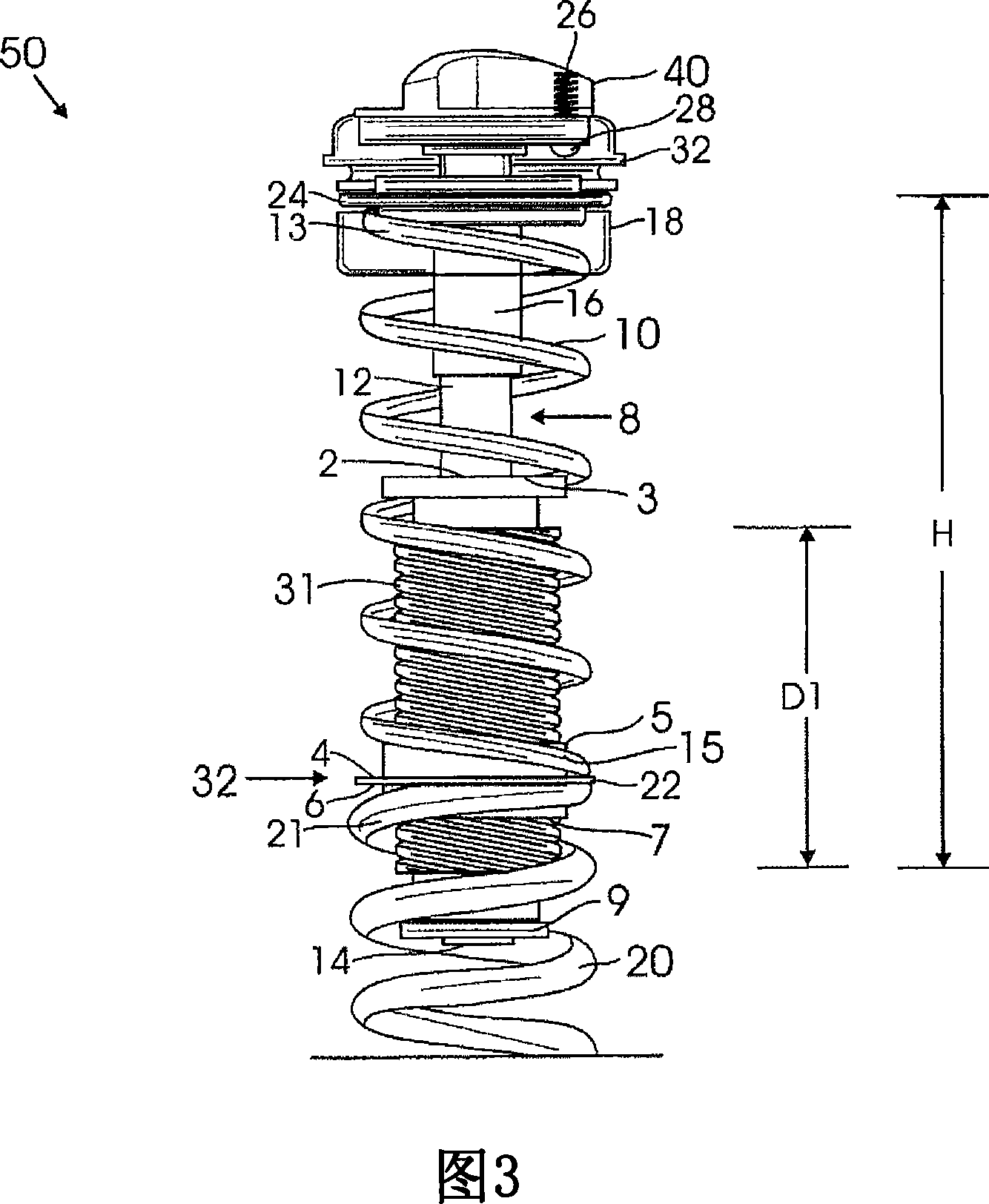

[0057] [0043] While specific embodiments of the invention will now be described with reference to the accompanying drawings, it is to be understood that these embodiments are exemplary only and are but a few of the many possible embodiments that may represent applications of the principles of the invention. Various changes and modifications apparent to those skilled in the art to which the invention pertains are deemed to be within the spirit, scope and contemplation of the invention as further defined in the appended claims.

[0058] [0044] Referring to FIG. 1, which is a partial front elevational view in cross section, there is illustrated a fork 100 incorporating an adjustable progressive coil spring system 50 of the present invention within a first fork leg 200. The first fork leg 200 is constructed by combining a set of two matched telescopic hollow rods (first inner telescopic hollow rod 202 and second outer telescopic hollow rod 204 ). Similarly, the second fork leg 201...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com