Hydraulic bracket with interconnected top and bottom

A hydraulic support and interconnected technology, applied in the direction of mine roof support, mining equipment, earthwork drilling, etc., can solve the problems of hydraulic support sliding or falling, unsatisfactory effect, low efficiency and other problems, so as to avoid sliding or falling, The effect of simplifying the support structure and stress state, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

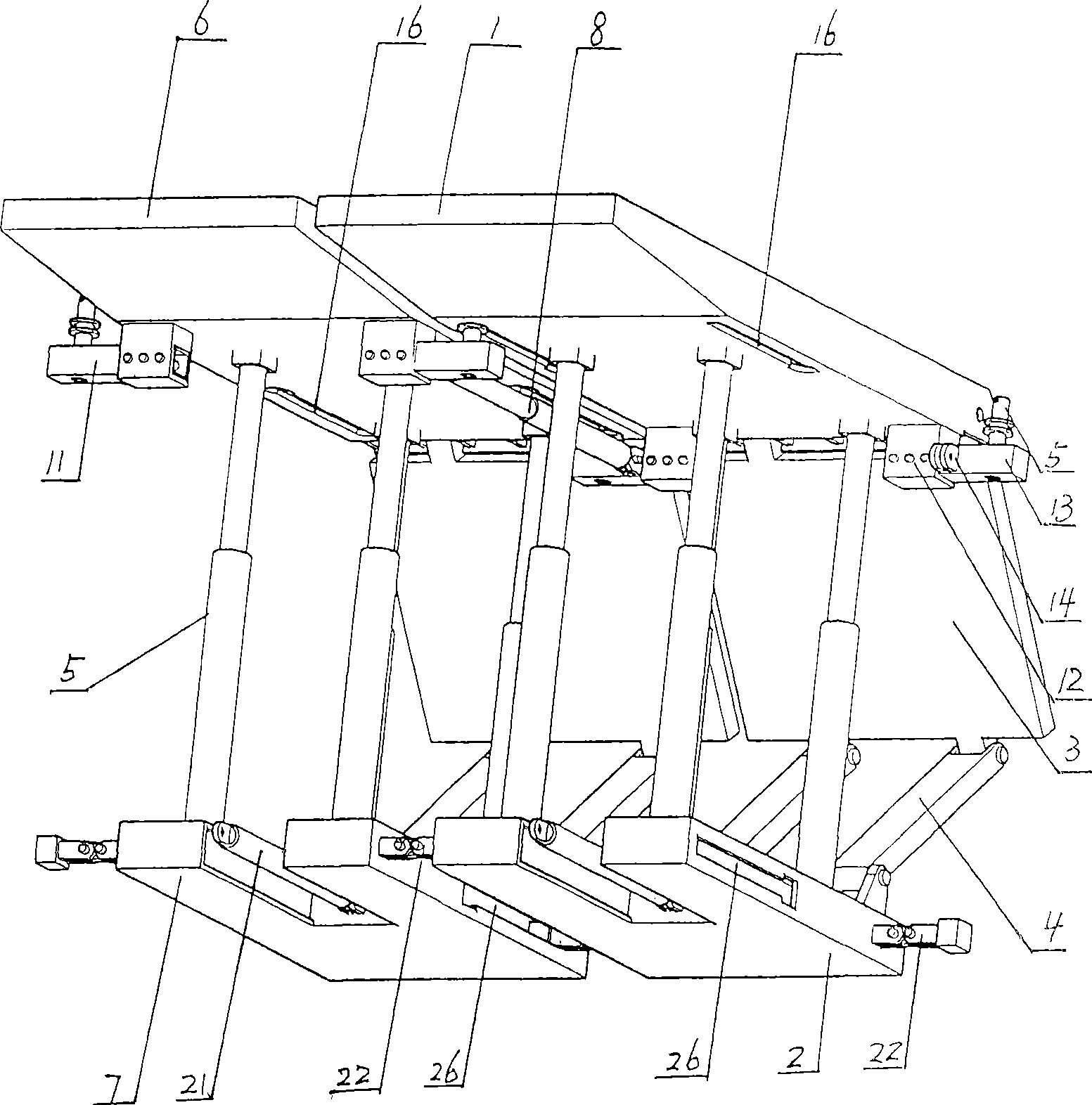

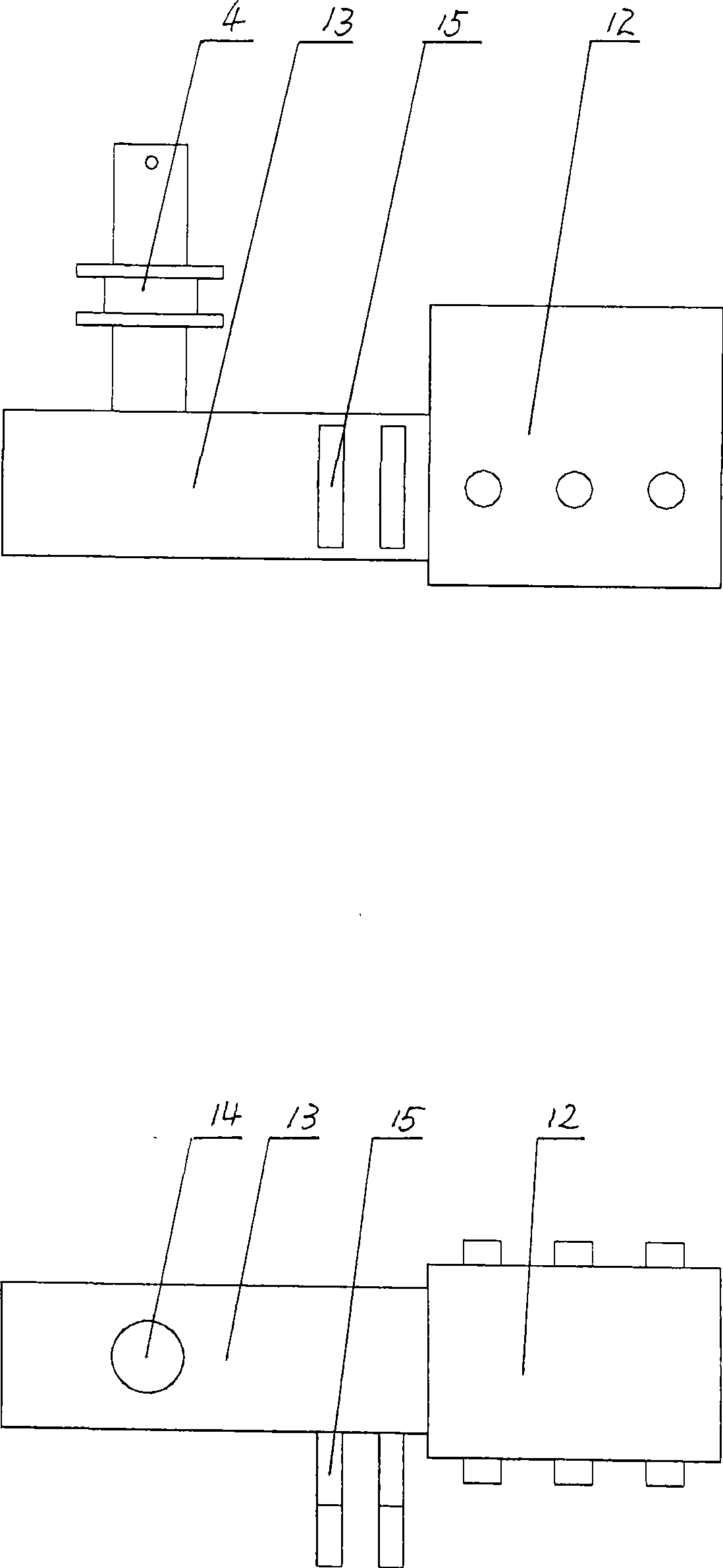

[0032] combine figure 1 , figure 2 , image 3 , a preferred embodiment of the present invention includes:

[0033] A top beam pushing device 11 is provided at the rear position below the top beam 1 of the pilot frame, and a top beam pushing device 11 is provided at the front position below the top beam 6 of the following frame. The top beam pushing device 11 is composed of a supporting sleeve 12, a pushing body 13, a guide body 14, a hinge seat 15, and a pushing guide rail 16. The supporting sleeve 12 is fixed under the top beams 1 and 6, and the pushing guide rails are arranged inside the top beams 1 and 6. One end of the push body 13 is connected with the support sleeve 12 fixed pins, the hinge seat 15 is arranged horizontally in the middle position, and the guide body 14 is vertically arranged at the other end, and the guide body 14 slides forward and backward in the push rail 16 and up and down.

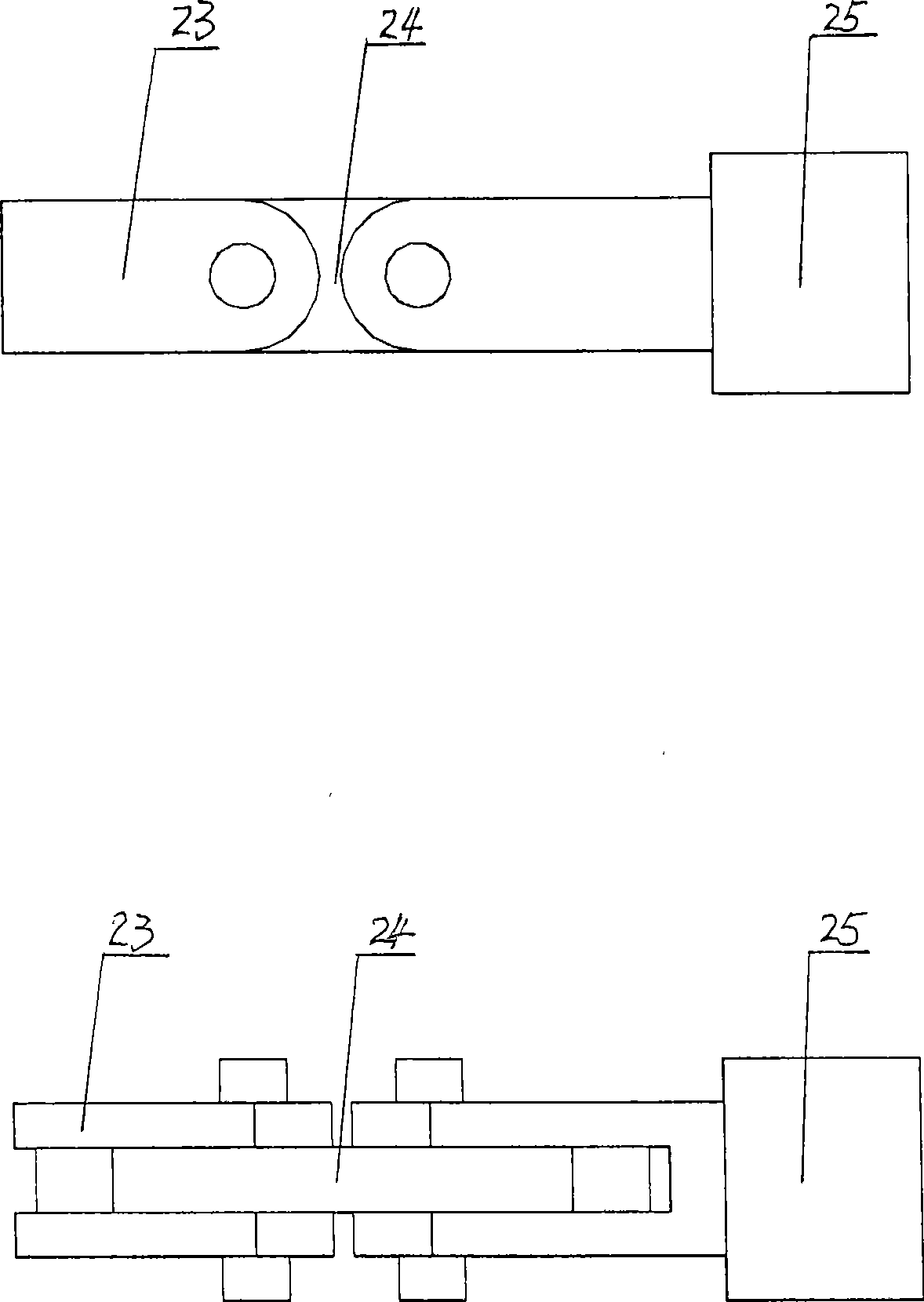

[0034] There are base jacks 21 connected to the conveyor in the middle o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com