Fixed constant velocity universal joint

A constant velocity universal joint, fixed technology, applied in the direction of elastic couplings, mechanical equipment, couplings, etc., to achieve the effect of improving rigidity, preventing deformation and preventing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0085] Below, based on Figure 1 to Figure 19 Basic embodiments of the present invention will be described. After that, based on Figure 20 to Figure 28 , Figure 29 to Figure 30 as well as Figure 31 to Figure 40 Three modified embodiments will be described.

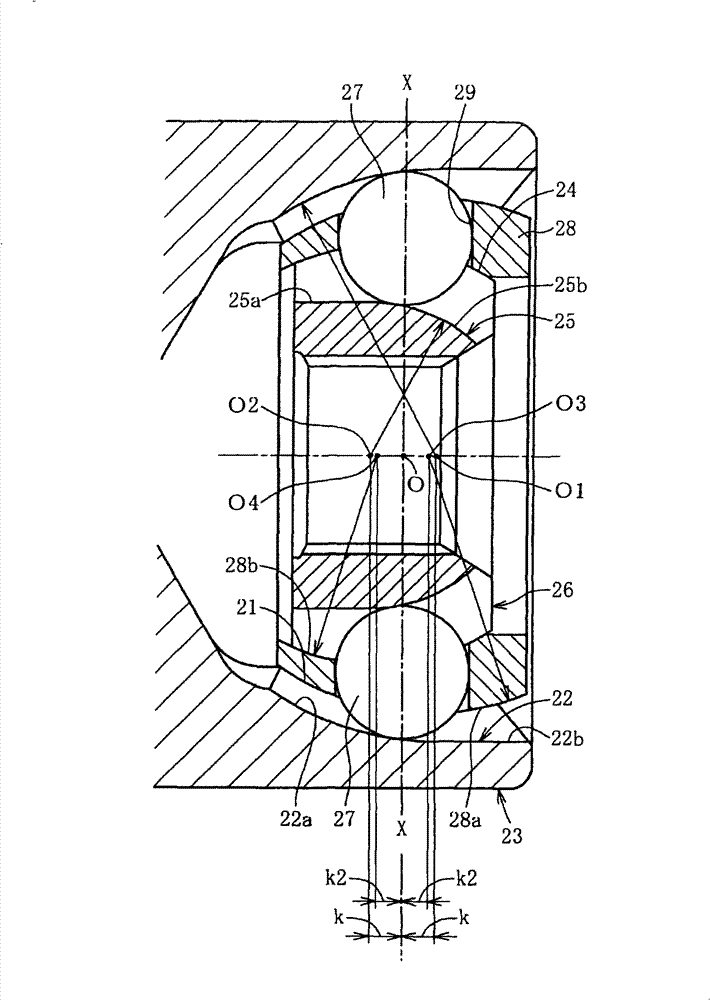

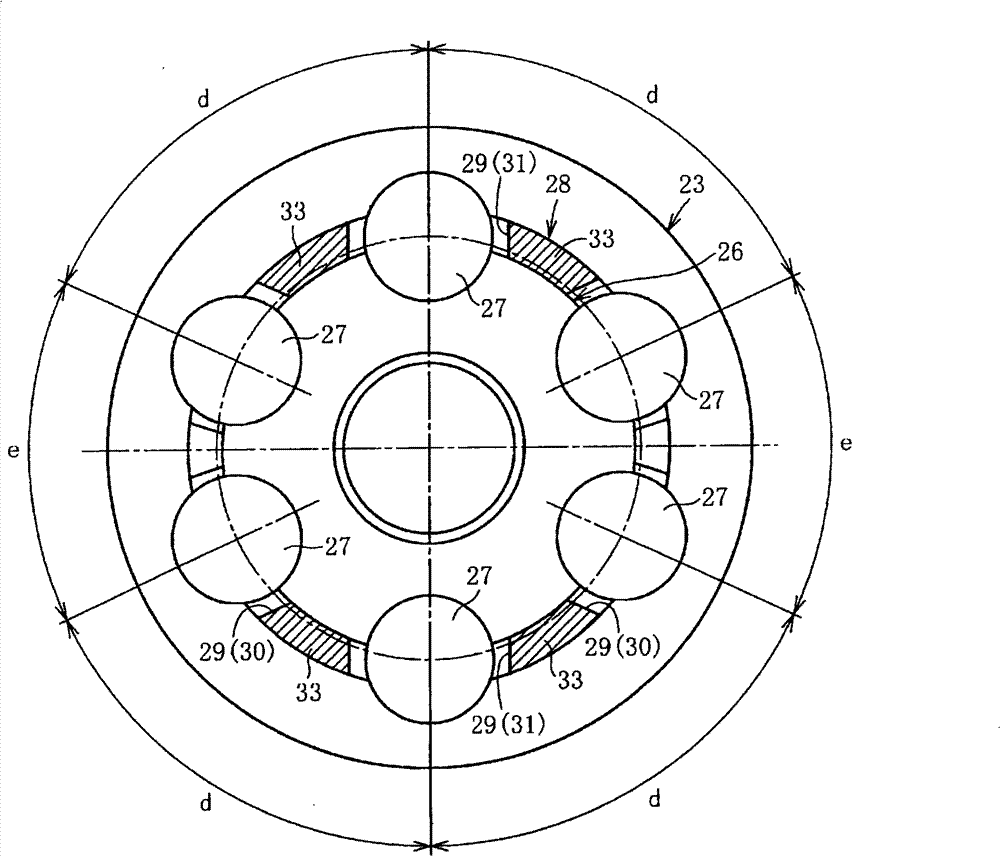

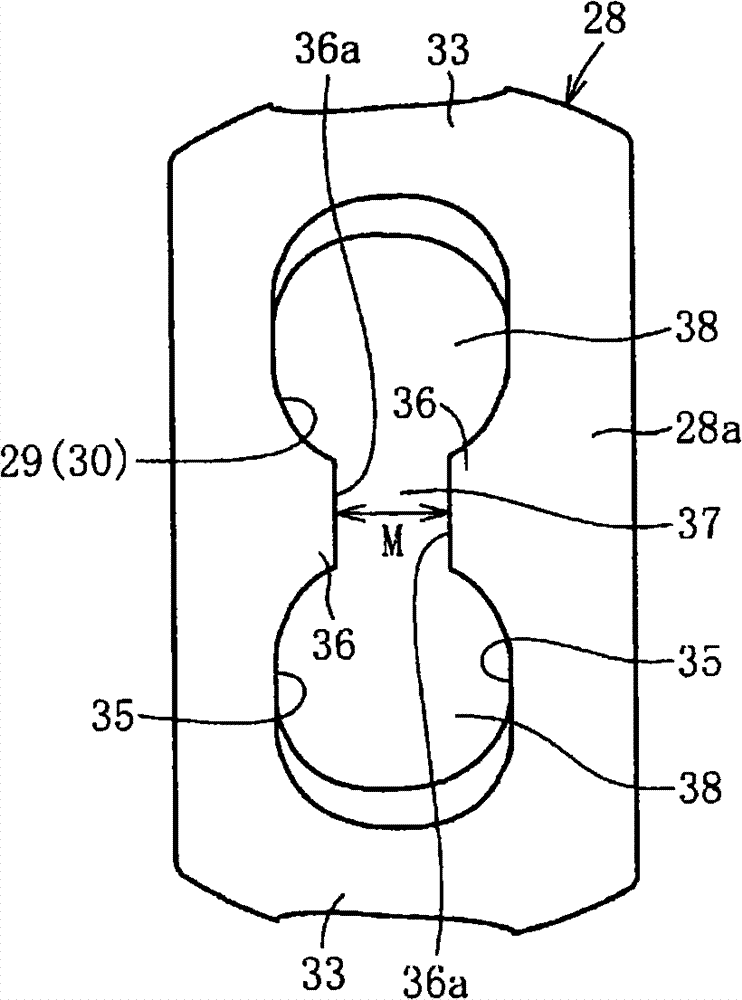

[0086] like figure 1 As shown, the fixed-type constant velocity universal joint according to the basic embodiment includes: an outer ring 23 as an outer member on which a plurality of track grooves 22 are formed in the axial direction at unequal intervals in the circumferential direction on the inner spherical surface 21; The spherical surface 24 is formed with a plurality of track grooves 25 paired with the track grooves 22 of the outer ring 23 in the axial direction at unequal intervals in the circumferential direction. The outer ring 26 is an inner member; A plurality of balls 27 for transmitting torque between the track grooves 25 of the inner ring 26 ; a cage 28 for holding the balls 27 between the inner sphe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com