Compressor and buffering element for fiber compressing apparatus

A buffer element and compression device technology, applied in the field of compressors, can solve the problems of increased noise and wear, and achieve the effect of simple replacement and accurate positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

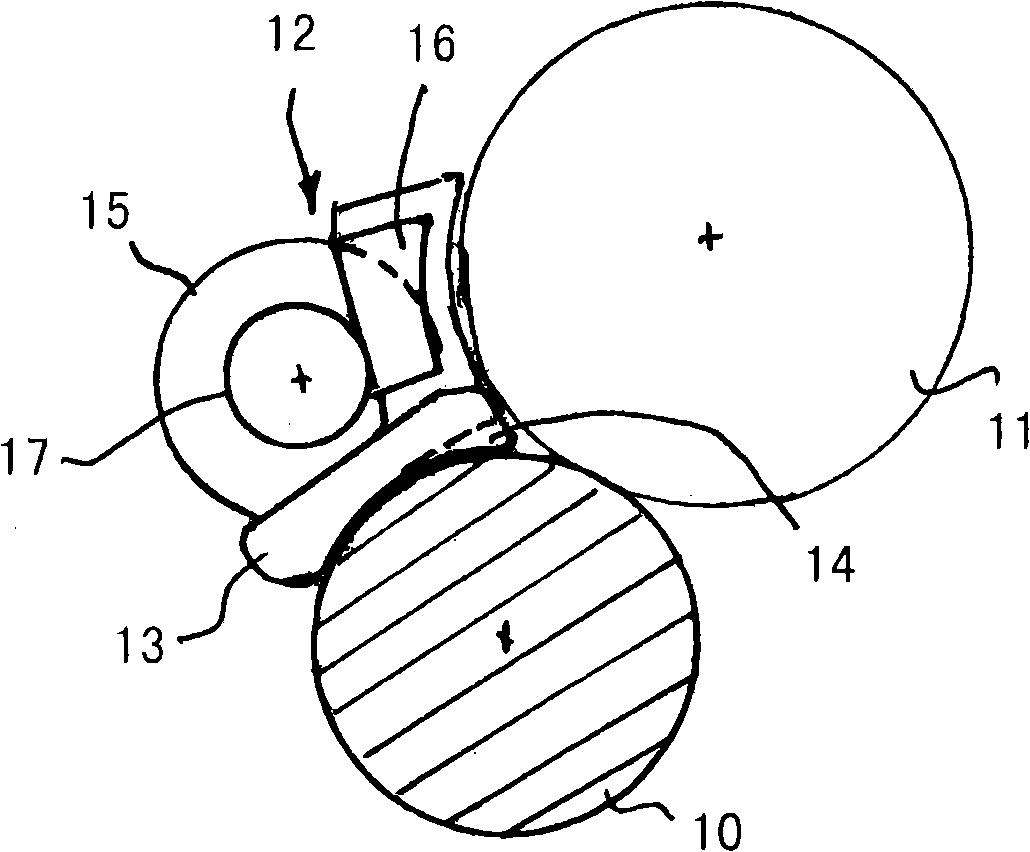

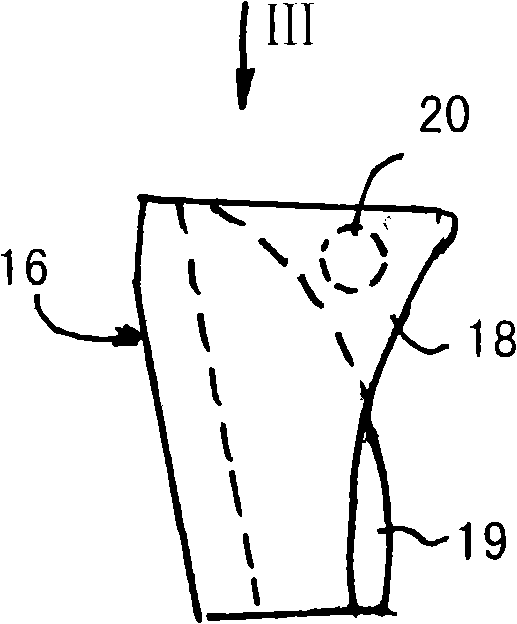

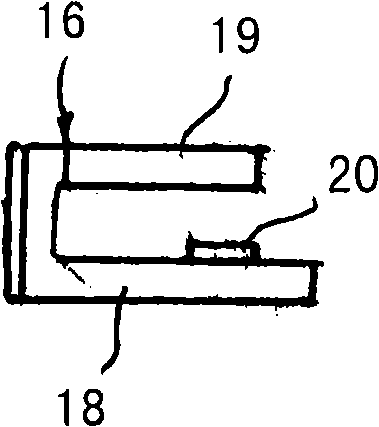

[0013] exist figure 1 shows a pair of output rollers of a drafting mechanism of a spinning machine, in particular a ring spinning machine. The delivery roller pair consists of a driven bottom roller 10 and a top roller 11 which run continuously in the longitudinal direction of the machine. The drafting mechanism includes at least one pair of conveying rollers and a pair of intermediate rollers. Between the middle pair of rollers and the pair of output rollers 10, 11 is the main compression zone. A double apron assembly is typically disposed in the primary compression zone.

[0014] Following the output roller pair 10, 11 is a device such as a ring spindle unit, by which the fiber strand drawn in the drafting mechanism is spun and twisted to produce the yarn. Between the output roller pair 10, 11 and the device for applying textile twist, a mechanical fiber compression device 12 is arranged, which compresses the fiber strands exiting from the delivery roller pair 10, 11 nip ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com