An electron column using a magnetic lens layer

A technology of electron column and magnetic lens, applied in nanotechnology, circuit, discharge tube and other directions for information processing, can solve the problem of difficult to precisely control the lens, and achieve the effect of reducing voltage, precise focusing, and easy deflection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] With reference to the following figures, various embodiments of the present invention will be described. At this point, it should be noted that various embodiments are used to illustrate the present invention so that those skilled in the art can easily understand the present invention, but are not intended to limit the rights of the present invention.

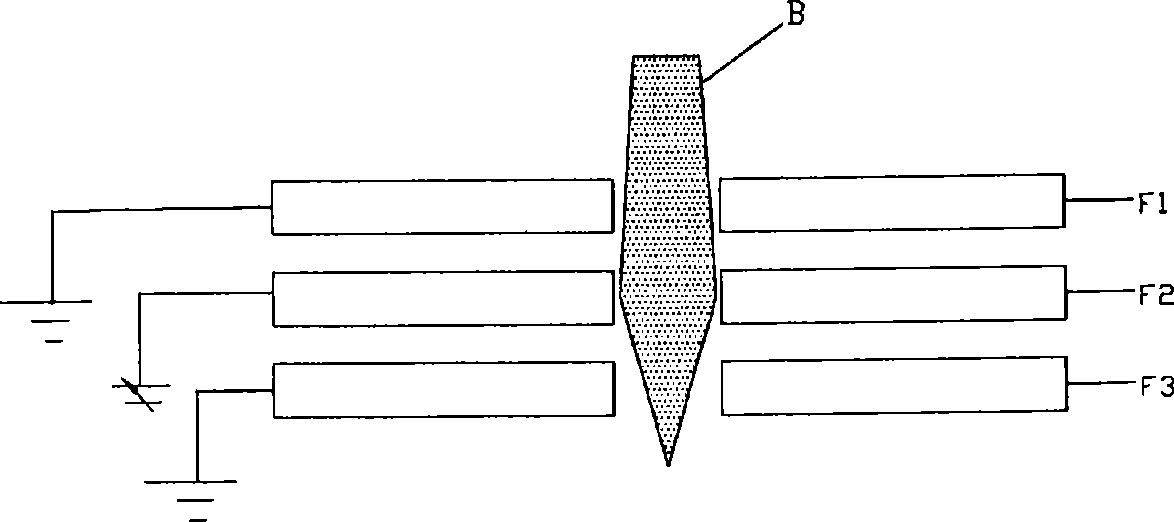

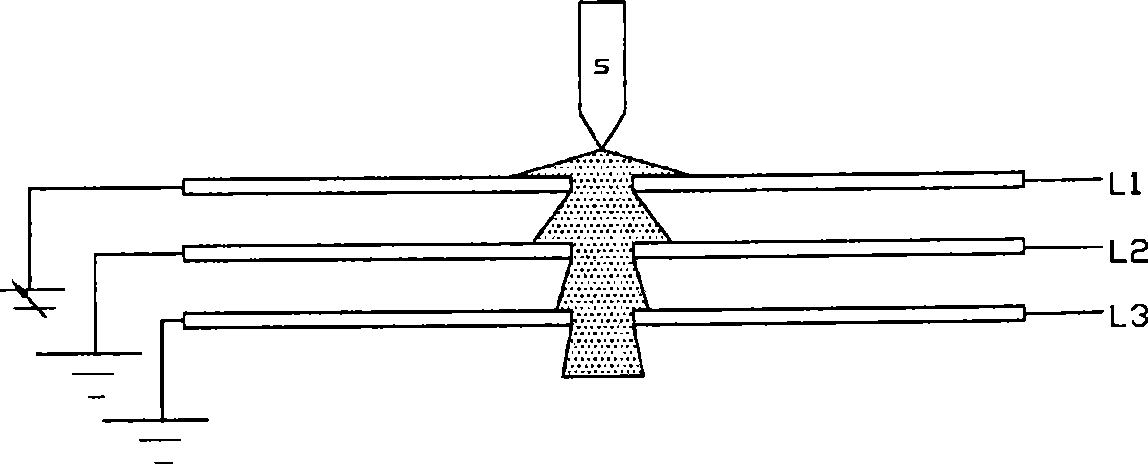

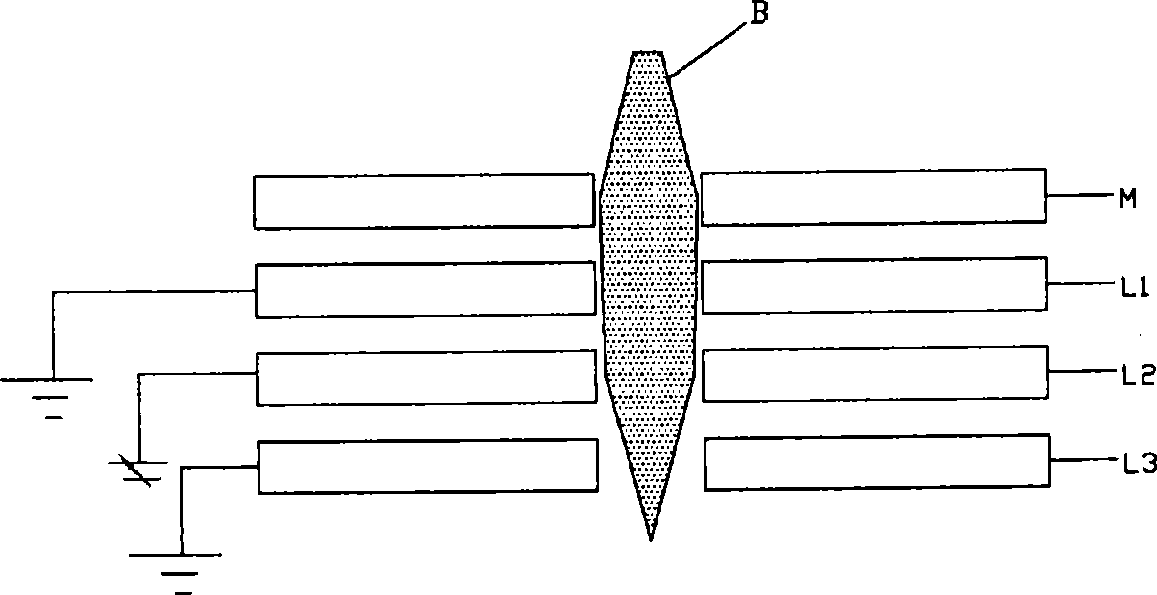

[0024] image 3 It is a cross-sectional view conceptually showing a section of a lens layer for focusing according to the present invention. Figure 4 To illustrate a cross-sectional view of an embodiment in which an electrode layer using a permanent magnet according to the present invention is used in a source lens. Figure 5 is a top view of a magnetic lens layer according to the present invention. Image 6 It is a top view of the electrode layer of a general electrostatic lens.

[0025] exist image 3 In , the uppermost electrode layer L1 and the lowermost electrode layer L3 are grounded, and the intermediate elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com