Linear electric motor mechanical characteristic test system and method

A technology of linear motor and mechanical characteristics, applied in the field of linear motor performance testing, can solve the problems of large influence of mechanical characteristics, fast response speed of ultrasonic motor, and inability to test the running speed of linear motor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

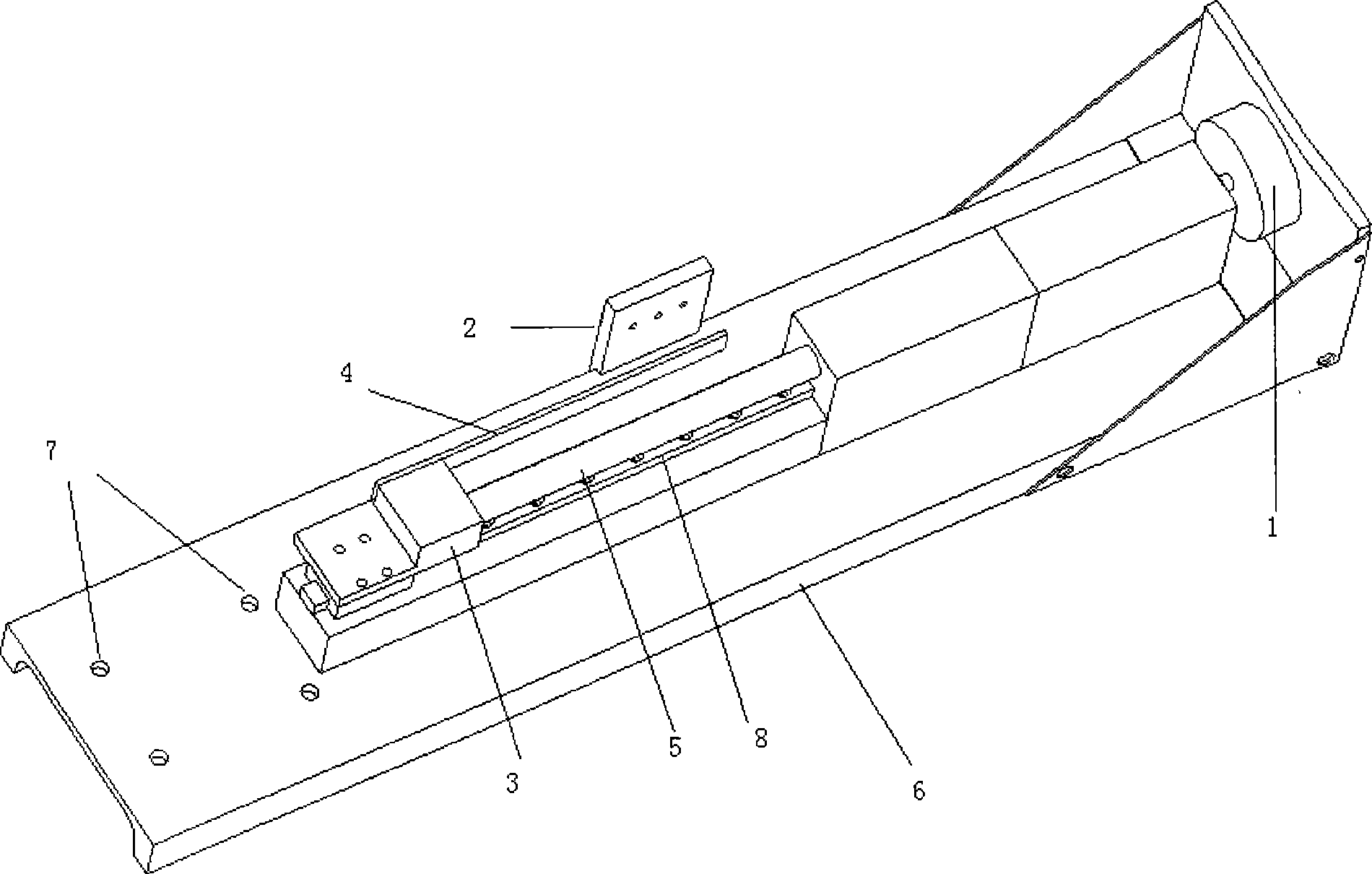

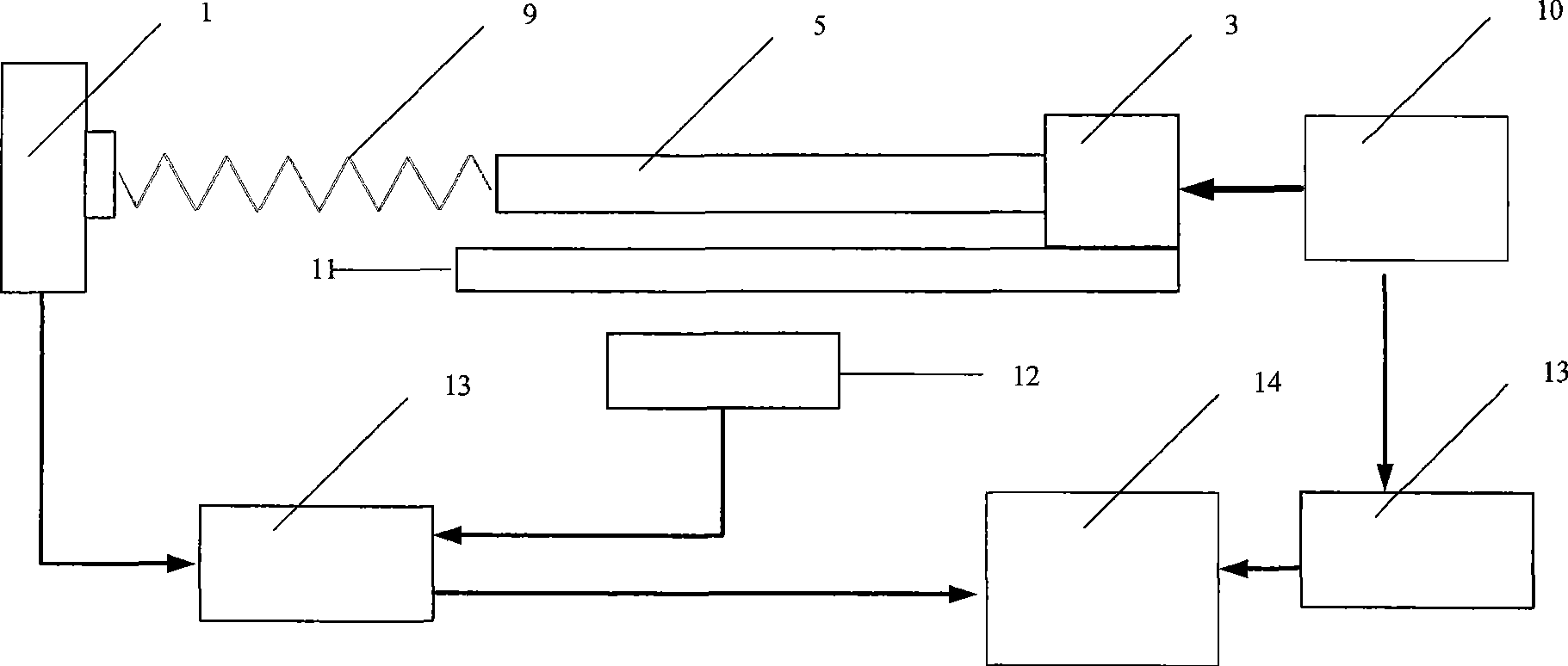

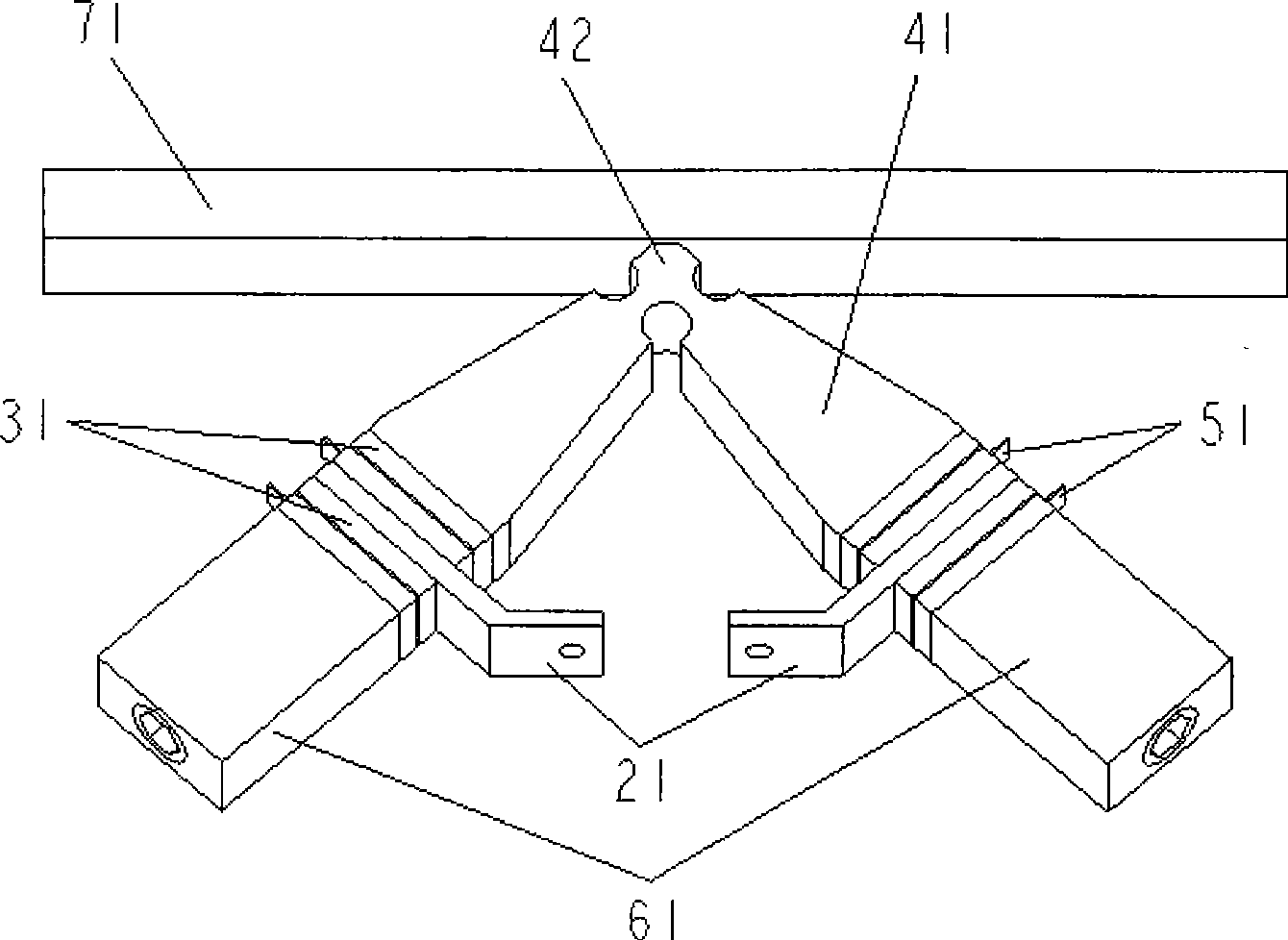

[0012] A test platform for testing the output force and speed of linear motors such as figure 1 shown. It is characterized in that: the test devices of the platform mainly include a pressure sensor and a grating line displacement sensor. Install the linear motor on the fixed slot, keep the mover of the linear motor on the same line as the shaft and the mass block; paste the grating scale with an appropriate length on the displacement scale, so that the reading head installed on the grating slot can be aligned with the motor. Collect the pulse count of the grating during the whole start and stop process; before the motor starts, put the mass block close to the mover of the linear motor, keep the two in contact and no other external force acts on the two. After the linear motor is started, the mover of the linear motor pushes the mass block and the sliding shaft to compress the spring at the front end of the sensor, and the spring produces compression deformation. At this time,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com