Positive and negative stacking device and method in stacking pants product

A trouser-shaped product and stacking technology is applied in the field of manufacturing front and back lamination devices for trousers-shaped products, which can solve the problems of easy-to-explode bags, inability to achieve staggered stacking of baby diapers, affecting packaging effects, etc., and achieves the effect of ensuring reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

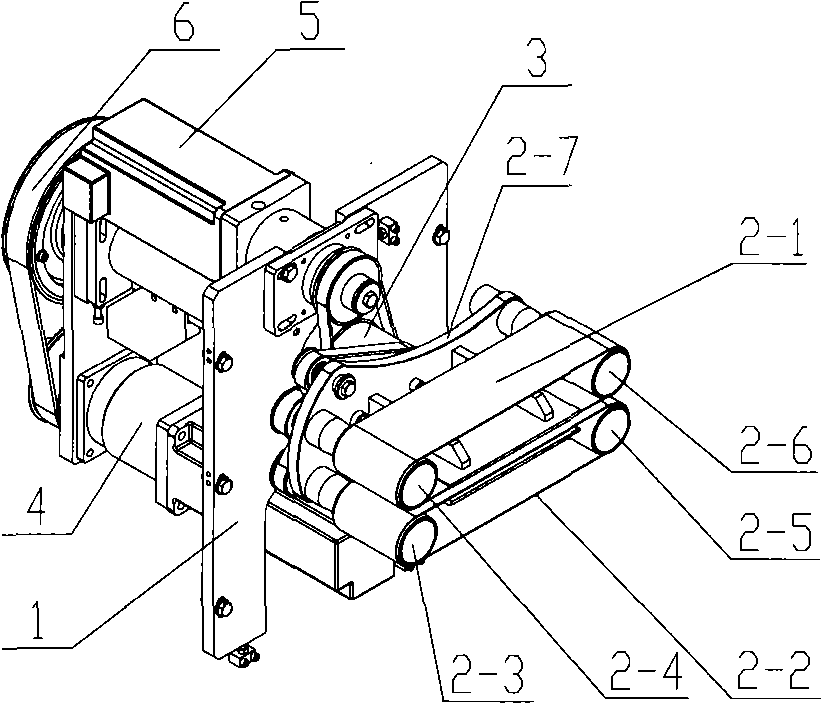

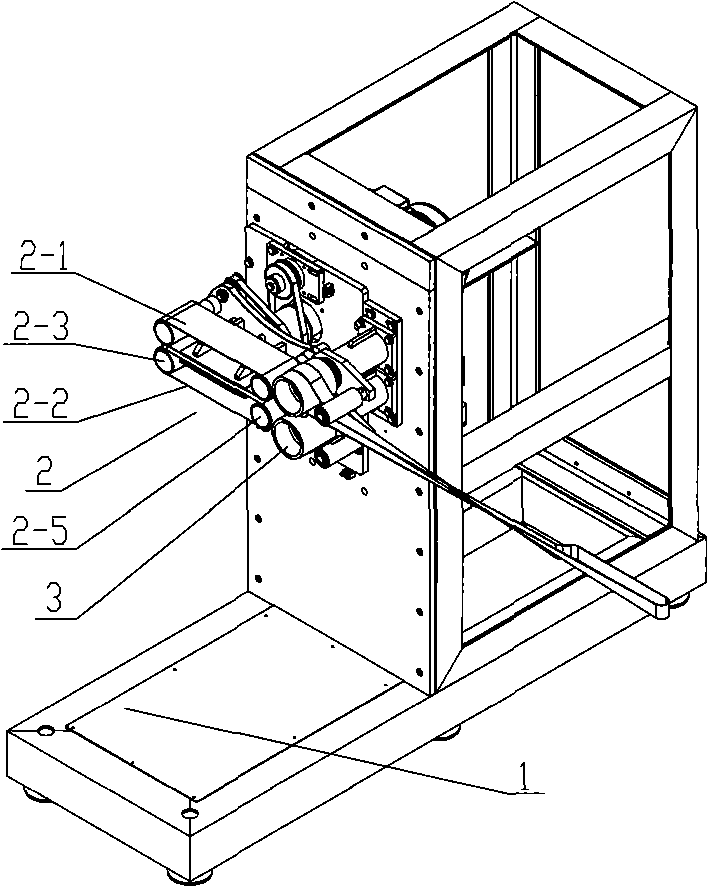

[0014] Embodiment 1: refer to figure 1 , 3 and 4. Pants-type product stacking front and back stacking equipment, which includes a frame 1 and a PLC controller. Conveying mechanism 2-2 is formed relatively, and upper circular conveying mechanism 2-1 is made up of two transmission shafts 2-4 and 2-6 and annular conveyer belt arranged at intervals, and annular conveyer belt is sleeved on two drive shafts 2 -4 and 2-6; the lower annular conveying mechanism 2-2 is composed of two transmission shafts 2-3 and 2-5 arranged at intervals and an endless conveyor belt, and the annular conveyor belt is sleeved on the two transmission shafts 2- 3 and 2-5, the opposite faces of the upper annular conveying mechanism 2-1 and the lower annular conveying mechanism 2-2 are the product conveying channel and the turning channel. The upper annular conveying mechanism 2-1 and the lower annular conveying mechanism 2-2 are driven by the conveying servo motor 5 on the frame 1 to drive the transmissio...

Embodiment 2

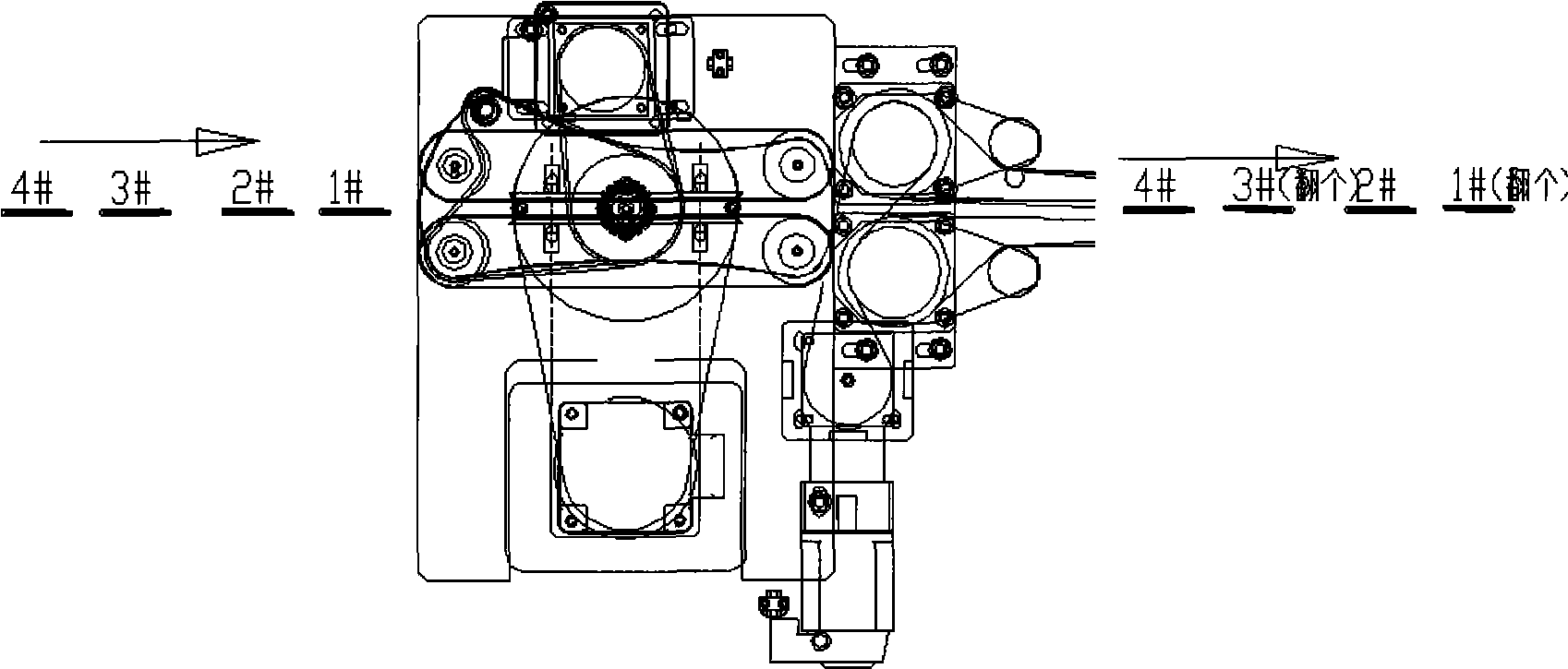

[0015] Embodiment 2: on the basis of embodiment 1, refer to figure 1 , 2 , 5 and 6. The lamination method of the front and back lamination equipment for stacking trousers products, which includes a PLC controller, the turning stop time of the rotary servo motor 4 and the forward and reverse conveying work of the conveying servo motor 5 are all controlled by the PLC controller. program, when the pants-type products need to be stacked in one positive and one reverse order, the first pants-type product completely enters the product conveying system formed by the opposite surface of the upper circular conveying mechanism 2-1 and the lower circular conveying mechanism 2-2. When in the channel, the PLC controller instructs the rotating servo motor 4 and the transmission mechanism 6 to drive the flipping plate 2-7 to make a flipping movement. When the flipping plate is flipped to 90 degrees, the PLC controller instructs the forward and reverse conveying servo motor 5 to make reverse...

Embodiment 3

[0016] Embodiment 3: on the basis of embodiment 1 and 2, with reference to figure 1 , 2 , 5 and 6. The lamination method of the front and back lamination equipment for stacking trousers products. When the trousers products need to be stacked in two positive and two reverse arrangements, the first two trousers are turned over and passed, and the third and fourth trousers are not turned over. Pass, the fifth and sixth pant products flip through, and so on.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com