Water and ink supply area safety protection device for offset machine

A safety protection device, offset printing machine technology, applied to printing machines, general parts of printing machinery, printing, etc., can solve problems such as arms or clothing being involved in the drum, machine operators being disabled, hair and clothing being entangled, etc., to achieve Increased protection range, simple and convenient installation, and fast response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

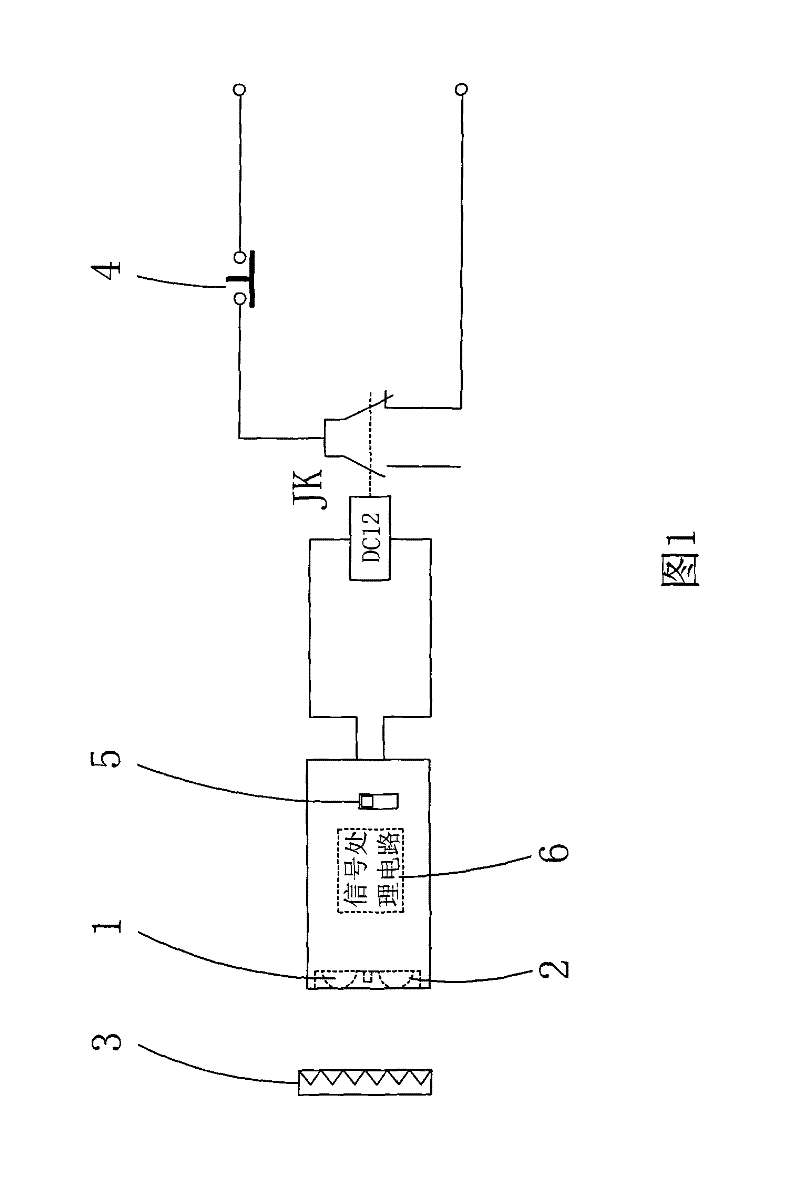

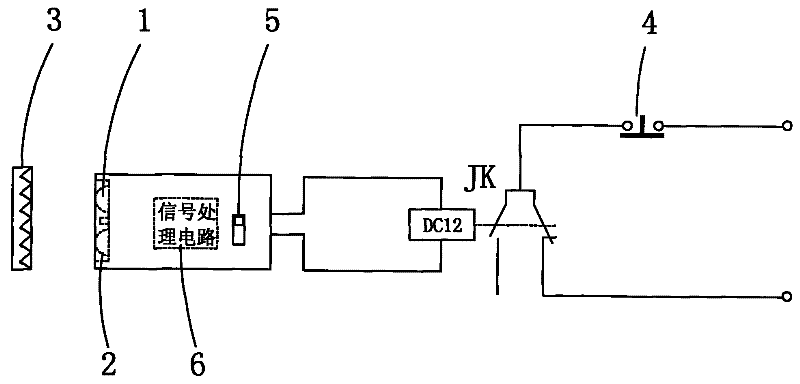

[0016] A safety protection device for the water supply and ink supply area of an offset printing machine, which uses an infrared protector as the main detection element. The infrared protector has two detection and sensing methods: reflection and opposite radiation. The reflection type is to install the infrared transceiver tube in the same condensing and transmissive plane shell, but the domestic transmission distance is only tens of centimeters, and the longest imported products are only 1.3 meters, but the cost is thousands of yuan. The through-beam type is to divide the infrared transmitting tube and the receiving tube into two groups to be opposite each other, and the transmission distance can reach tens of meters, but because the through-beam type is a two-group transmission control line device. It is difficult to install two opposite transmission control lines on the large steel frame mechanism of the printing machine. It is difficult to perforate and fix the two trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com