Embedded moving type muffler apparatus for drum

A muffler device and movable technology, applied in percussion instruments, instruments, musical instruments, etc., can solve problems such as affecting sound quality, affecting sound wave transmission, and sound waveforms not resonating, achieving the effect of small impact on drum sound quality and solving the problem of disturbing people.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

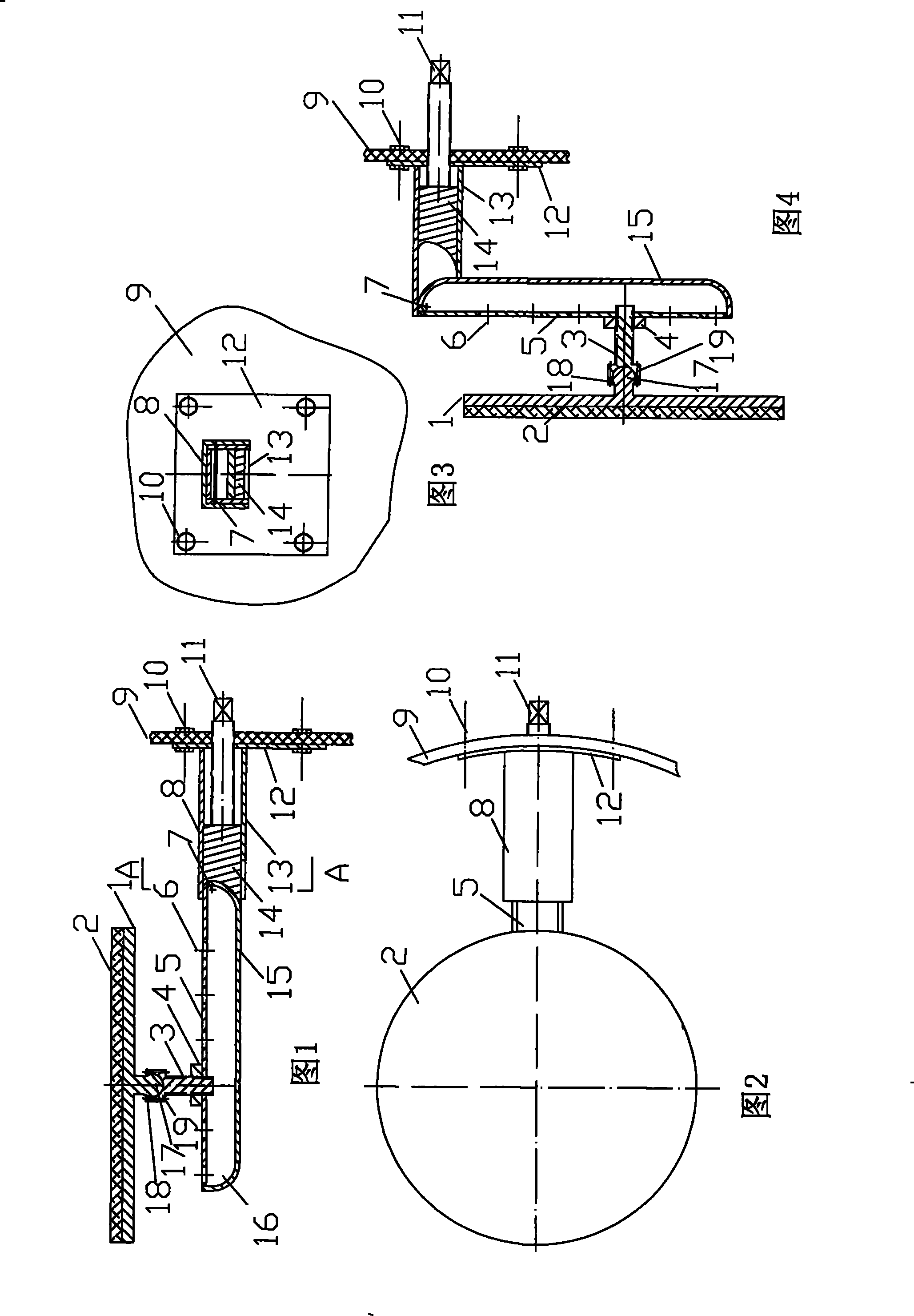

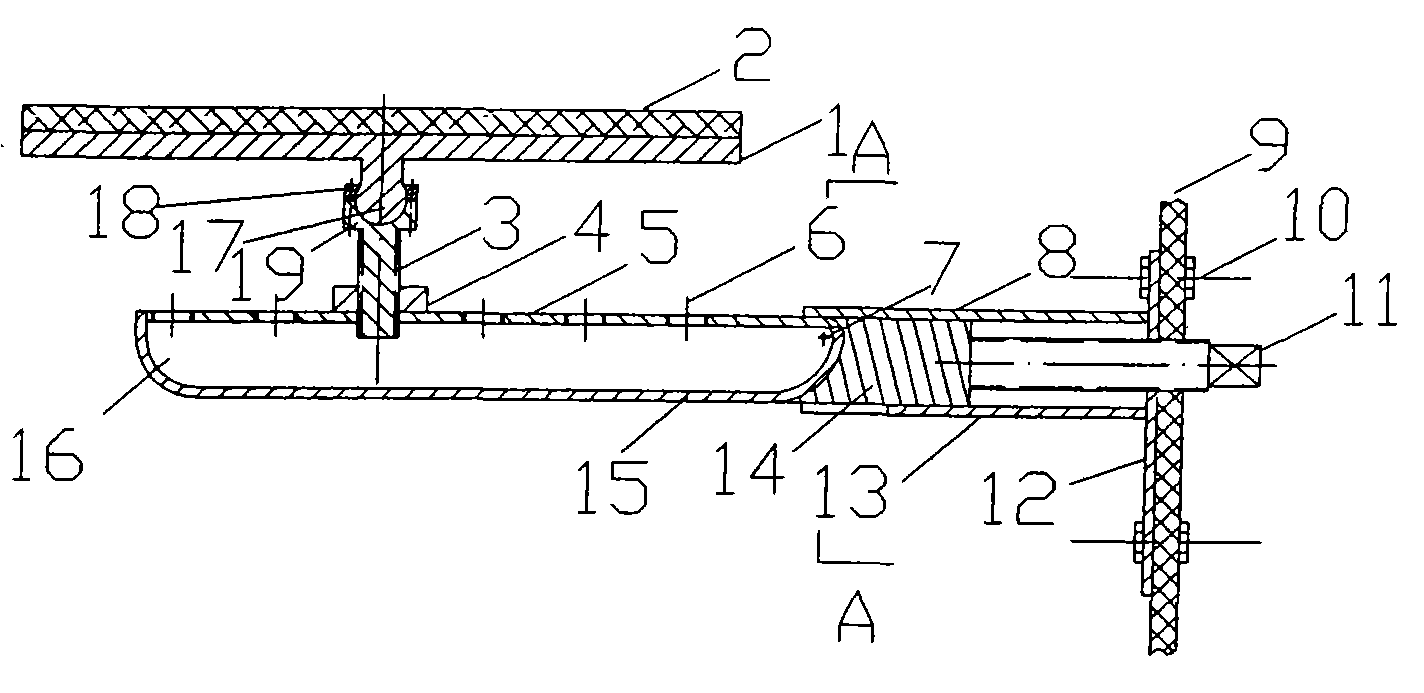

[0021] As shown in the figure, a built-in movable drum silencing device is composed of a drum silencing pad supporting plate 1 and a silencing pad 2 attached to the upper part of the drum silencing pad supporting plate 1, and a vertical Support bar 3, vertical support bar 3 is fixed on the top of movable cross bar 16, and the right end surface of movable cross bar 16 is the irregular arc surface that gradually rises from left to right, and movable cross bar 16 is fixed on fixed by shaft 7 rotation. In the cavity at the left end of the cross bar, the cross-sectional shape of the fixed cross bar inner cavity matches the cross section of the movable cross bar 16, and the left end of the fixed cross bar inner cavity has a gap for the movable cross bar 16 to turn downwards. The cavity is provided with a slide block 14 whose shape matches the cavity of the fixed cross bar. The left end surface of the slide block 14 is provided with an irregular arc surface matched with the right end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com