Gas shock testing machine for detecting fragile cover of projectile storage and transportation launching tube

A technology of impact testing machine and launch tube, which is applied to measurement devices, instruments, scientific instruments, etc., can solve problems such as undiscovered research, development and application reports, and achieve the effects of improved safety and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with specific examples.

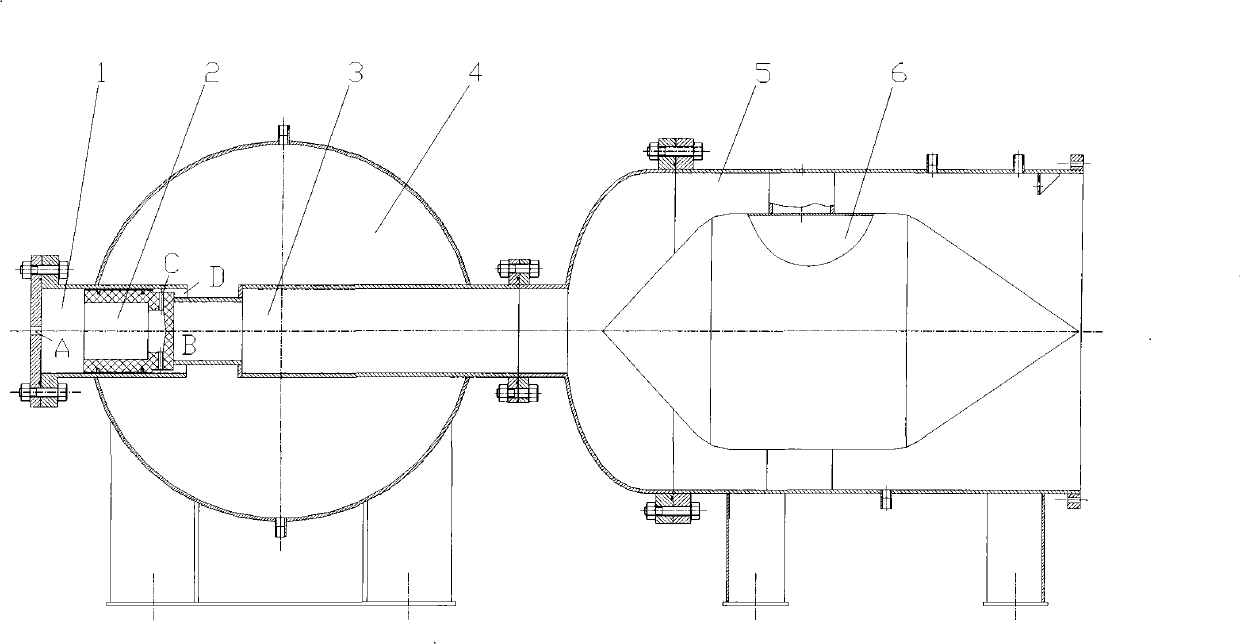

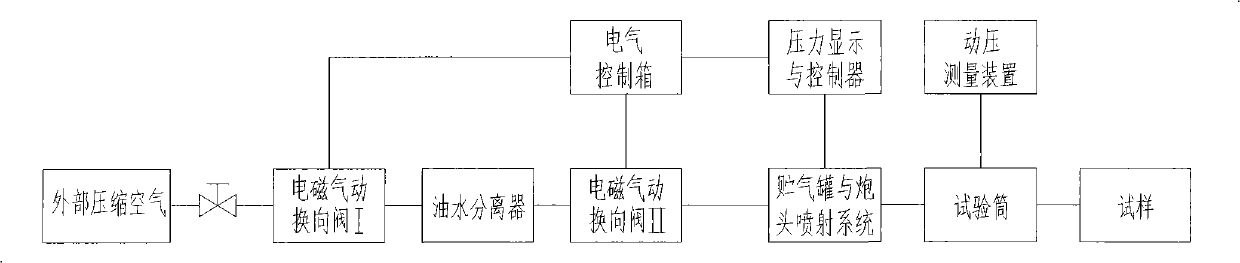

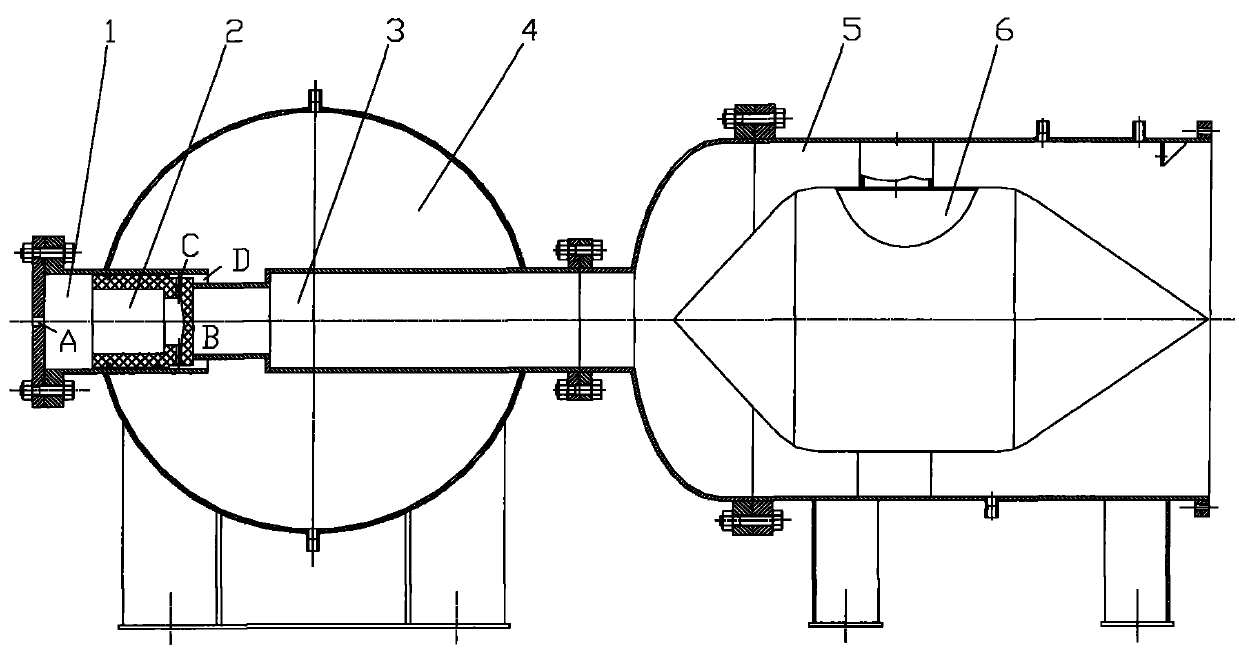

[0022] Take a certain type of missile as an example below to illustrate embodiments of the present invention. The structure diagram of the present invention is as figure 1 ; Structure block diagram such as figure 2 .

[0023] The testing machine in this example is used for the dynamic blasting performance test of the fragile front cover of a certain type of missile storage and transportation launcher. When the testing machine enters the inflated state, the electromagnetic pneumatic reversing valve I (normally closed type) is opened due to energization, the electromagnetic pneumatic reversing valve II (normally open type) is kept open due to no energization, and the intake pipe is completely connected. Depend on figure 1 It can be seen that the compressed air enters the cylinder through the air inlet and outlet A, pushes the piston to the right and presses the nozzle B tig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com