Two-faced adhesive tape and production method thereof

A double-sided tape and adhesive layer technology, applied in the direction of adhesives, film/sheet adhesives, coatings, etc., can solve the problems of man-hours, energy, materials, complicated production processes, and increased product packaging costs. , to achieve the effect of less material, low production cost and good use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

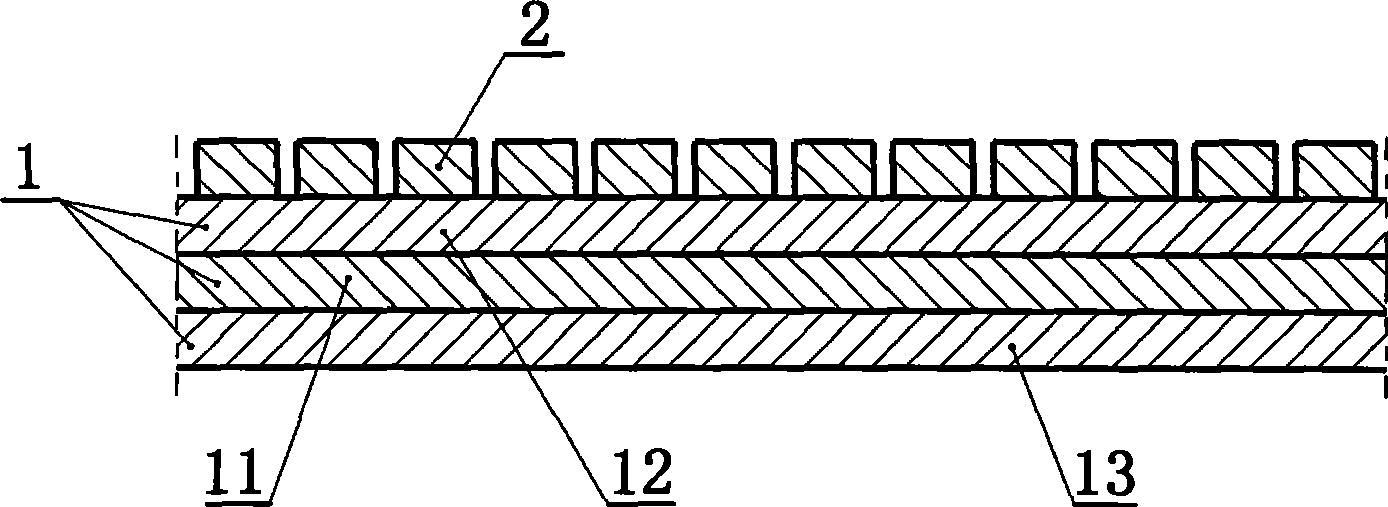

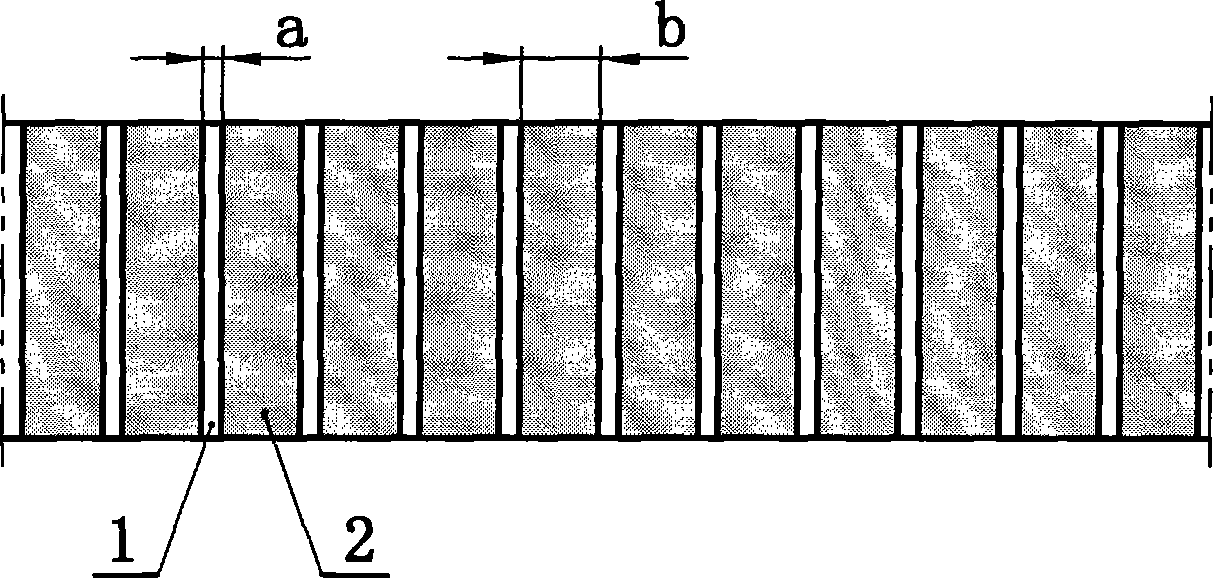

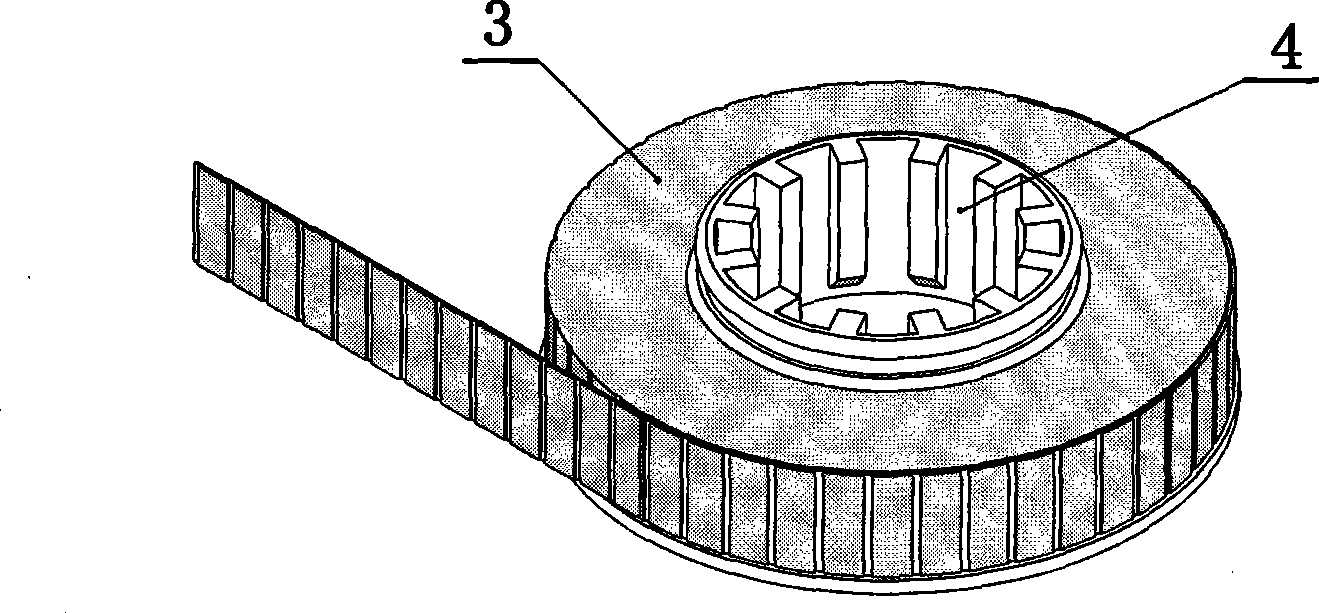

[0020] see Figure 1 ~ Figure 2 As shown, the double-sided adhesive tape of the present invention comprises a release paper layer 1 composed of a base layer 11 and its upper and lower surfaces coated with an upper release layer 12 and a lower release layer 13. In the release paper layer 1 The upper surface of the release paper layer 1 is coated and connected with an adhesive layer 2. The above is the prior art. The pressure-sensitive adhesive film unit is composed of independent pressure-sensitive adhesive film units. The thickness of the pressure-sensitive adhesive film unit is selected within the range of 0.01-0.1mm, and its width b is selected within the range of 0.5-8mm. The distance between the sides of each adjacent unit of the pressure-sensitive adhesive film The spacing a is selected within the range of 0.15-3mm. In this embodiment, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com