Arsenic removing apparatus for drinking water

A drinking water and water inlet technology, applied in water/sewage treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as difficult regeneration, short service life of adsorption materials, arsenic pollution in drinking water, etc. , to achieve the effects of fast adsorption/desorption rate, mild reaction conditions and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0057] Preparation of nano-adsorbent material in the filter element on the left:

[0058] At room temperature, the prepared nanometer adsorption material is used for intermittent arsenic removal. Pass the water sample with arsenic concentration of 2000μg / L through the column, the removal rate of arsenic is as high as 99.5%, and the concentration of arsenic in the effluent is less than 10μg / L, which meets the new arsenic content standards established by the European Union and the United States.

Embodiment 1

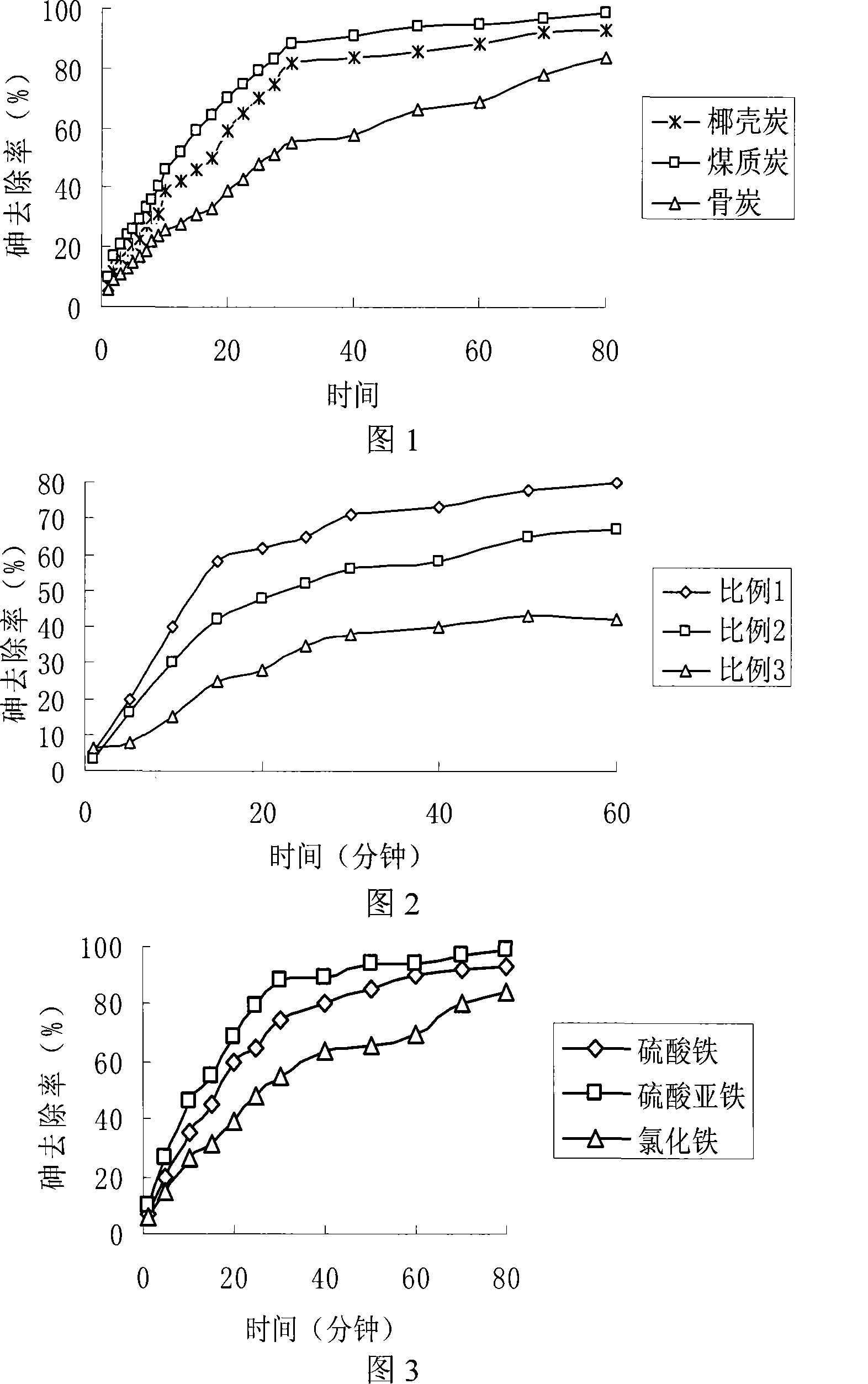

[0060] The selected materials are: choose different matrix activated carbon: coconut shell carbon (pore volume is 0.326cm 3 / g), coal-based carbon (pore volume is 0.145cm 3 / g), bone charcoal (pore volume is 0.250cm 3 / g); ferric chloride, potassium borohydride, organic solvents (common), monoalcohols (C 1 -C 10 ), low-carbon polyol series (C 1 -C 10 ), polyethylene glycol series (200-40000), anaerobic water, inert gas (common), etc.

[0061] The specific steps are:

[0062] (1) select commercially available coconut shell charcoal (the pore volume is 0.326cm 3 / g), coal-based carbon (pore volume is 0.145cm 3 / g), bone charcoal (pore volume is 0.250cm 3 / g) and other activated carbon materials, washed 3 times with deionized water, and then ultrasonically treated for 30min;

[0063] (2) At room temperature, in a 250ml three-neck flask equipped with a magnetic stirrer, activated carbon, and a dropping funnel, add 30 ml of 0.15M ferric chloride solution (coconut shell cha...

Embodiment 2

[0069] The selected material is: activated carbon (obtained from coal-based carbon treatment, with a pore volume of 0.168cm 3 / g), ferrous sulfate, potassium borohydride, organic solvent (common), ethanol, glycerin, polyethylene glycol 200, polyethylene glycol 4000, anaerobic water, inert gas (common), etc.

[0070] The specific steps are:

[0071] (1) Select the pore volume as 0.168cm 3 / g of commercially available coal-based activated carbon, washed 3 times with deionized water, and then sonicated for 30 min;

[0072] (2) At room temperature, in a 250ml there-necked flask equipped with a magnetic stirrer, gac, and dropping funnel, add 30 milliliters of 0.2M ferrous sulfate solution (soak the coal-based charcoal in advance for 60 minutes with ferrous sulfate), Then 45 ml of dispersant (ratio 1 of ethanol, glycerol, polyethylene glycol 200 and 4000 is 1:1:1, ratio 2 is 2:2:0.5, ratio 3 is 2:1:0.1) is added.

[0073] (3) Under the protection of inert gas (flow rate 60 ml / min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com