Mint type cigarette

A cigarette and mint technology, applied in tobacco, cigar manufacturing, textiles and papermaking, etc., can solve the problems of high risk and volatility, and achieve the effects of improving the wrapping degree, reducing heat volatility, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

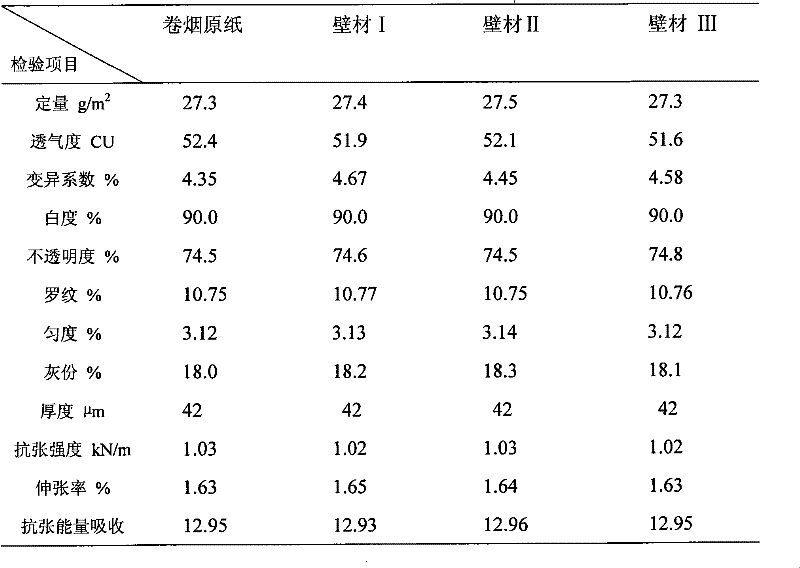

Embodiment 1

[0042] According to the conventional method, the fiber raw materials are thawed and beaten, the proportion of long and short fibers is adjusted, fillers and functional additives are added, and then dehydrated paper is formed, and then pressed, dried, coiled, and cut to complete the manufacture of cigarette paper; through adjustment The degree of beating, slurry flow rate and vehicle speed make the cigarette paper weight 29 g / m 2 , Air permeability 60 Coresta.

[0043] Get 700 kilograms of wood pulp, add 500 kilograms of calcium carbonate, prepare the potassium citrate of 40% by weight and the sodium citrate of 6% by weight and add at the place where the combustion aid is added.

[0044] Prepare a 60% cyclamate solution by mass, add 20% menthol in it, stir well, let stand overnight at low temperature (0°C), disperse with a high-pressure disperser at 18,000rpm for 2 minutes, and homogenize twice under high pressure , and then filtered, precipitated, and vacuum-dried at 65°C to ...

Embodiment 2

[0048] According to the conventional method, the fiber raw materials are thawed and beaten, the proportion of long and short fibers is adjusted, fillers and functional additives are added, and then dehydrated paper is formed, and then pressed, dried, coiled, and cut to complete the manufacture of cigarette paper; through adjustment The degree of beating, slurry flow rate and vehicle speed make the cigarette paper weight 29 g / m 2 , Air permeability 60 Coresta.

[0049] Get 700 kilograms of wood pulp, add 500 kilograms of calcium carbonate, prepare the potassium citrate of 40% by weight and the sodium citrate of 6% by weight and add at the place where the combustion aid is added.

[0050] Prepare a cyclodextrin solution with a mass percentage of 60%, add menthol with a mass percentage of 40%, stir evenly, let stand overnight at low temperature (0° C.), disperse with a high-pressure disperser at 22,000 rpm for 1 min, and homogenize two times, and then filtered, precipitated, and...

Embodiment 3

[0054] According to the conventional method, the fiber raw materials are thawed and beaten, the proportion of long and short fibers is adjusted, fillers and functional additives are added, and then dehydrated paper is formed, and then pressed, dried, coiled, and cut to complete the manufacture of cigarette paper; through adjustment The degree of beating, slurry flow rate and vehicle speed make the cigarette paper weight 29 g / m 2 , Air permeability 60 Coresta.

[0055] Get 700 kilograms of wood pulp, add 500 kilograms of calcium carbonate, prepare the potassium citrate of 40% by weight and the sodium citrate of 6% by weight and add at the place where the combustion aid is added.

[0056] Prepare a modified starch solution with a mass concentration of 40%, add menthol with a mass fraction of 10%, stir evenly, let stand overnight at low temperature (0°C), disperse with a high-pressure disperser at 22000rpm for 2min, and homogenize twice under high pressure. Then, it is suction f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com