Built-in joint meter and method for detecting openness of slit

A seam meter and embedded technology, applied in the field of embedded seam meter, can solve the problems of difficult protection of orifice instruments, poor observation effect, complicated implementation process, etc., and achieve reasonable setting, convenient and reliable positioning, and high detection accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

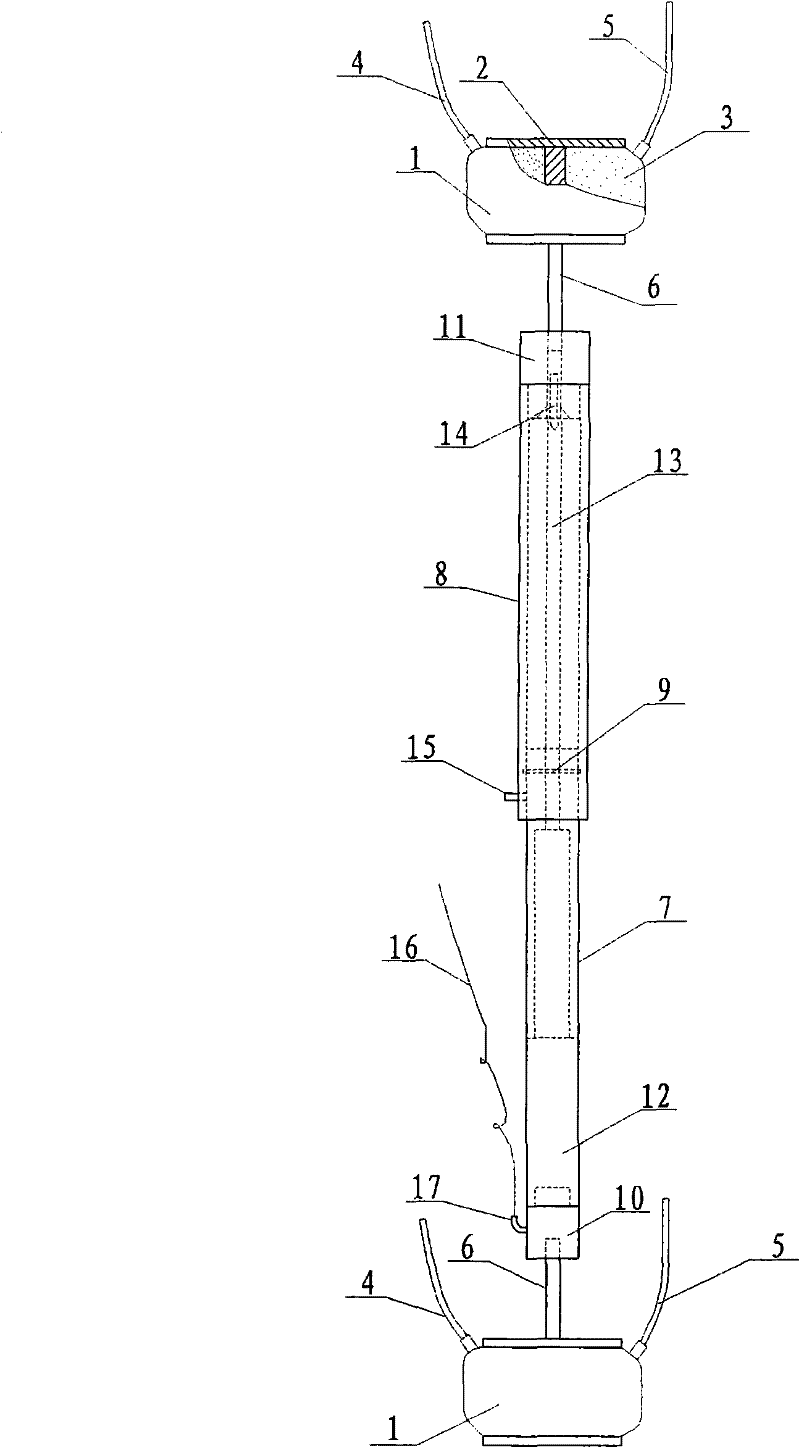

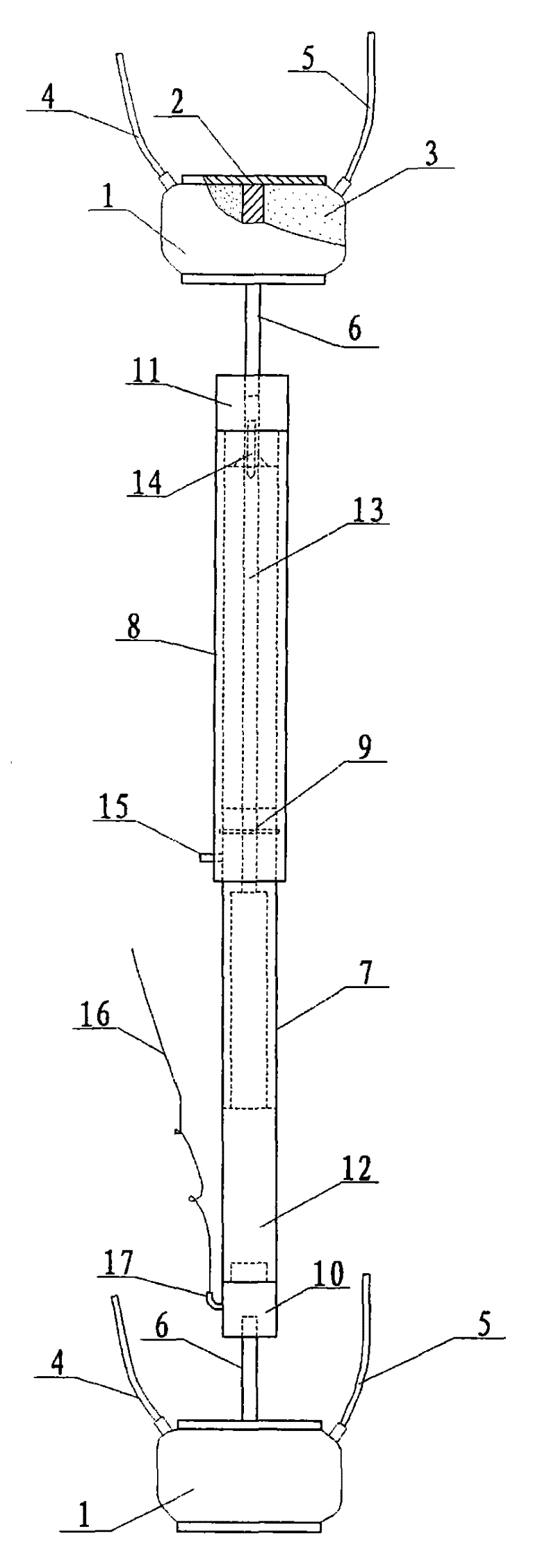

[0017] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings. It includes a sensor sheath and a displacement sensor installed in the sensor sheath. The sensor sheath is a sliding telescopic sheath, which is formed by connecting the inner and outer sleeves 7 and 8. The inner and outer sleeves are made by engineering Made of plastic PVC, a sealing ring 9 is arranged at the near port of the outer casing to match with the inner casing to keep the sealing of the inner hole of the sliding telescopic sheath, and a damping screw 15 is also arranged on the side of the outer casing port for Adjust the sliding resistance of the inner and outer sleeves; a high-precision displacement sensor 12 is installed in the inner hole of the sliding telescopic sheath, and the displacement sensor is a string sensor. The main parameters are: range 25-50mm, sensitivity 0.02% F.S, temperature range -20 -+80°C; joints 10 and 11 are respectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com