Labor-saving transmission mechanism of bike

A transmission device and bicycle technology, which is applied in the field of vehicles, can solve the problems of short arm length, less labor saving, and difficulty in synchronous circular motion of the transmission rod.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

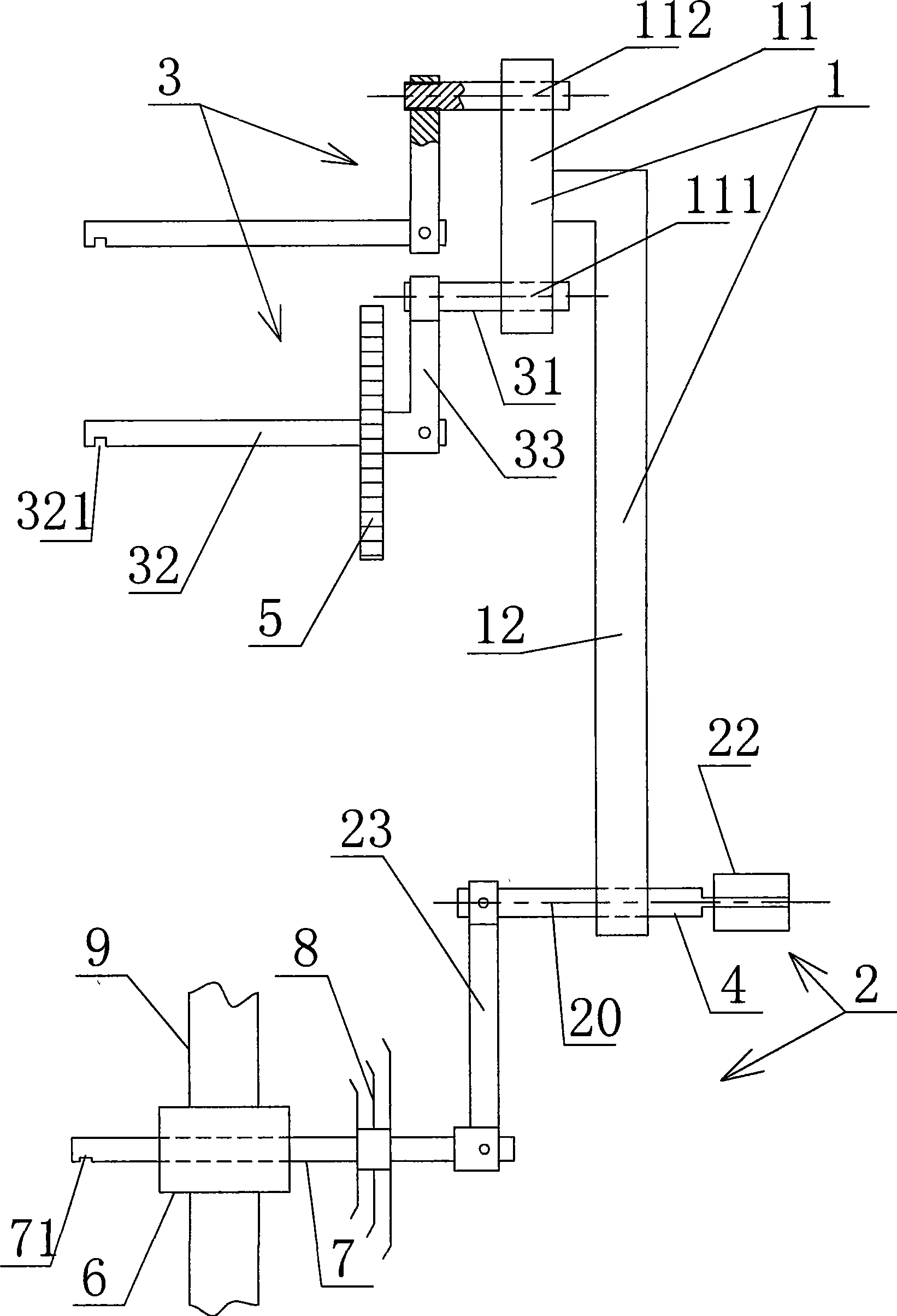

[0014] Such as figure 1 As shown, Embodiment 1 of the bicycle labor-saving transmission device of the present invention includes a transmission member 1, a pedal or handle device 2 connected to one end of the transmission member 1, a pair of "Z" shaped connecting rods 3 connected to the other end of the transmission member 1, and a pedal Or the connecting action centerline 20 of the handle device 2 connected to the transmission part 1 and the connection action centerlines 111, 112 of the two "Z" shaped connecting rods 3 connected to the transmission part are parallel to each other; each "Z" shaped connecting rod 3 is Comprising a pair of cross bars 31, 32 parallel to each other and a vertical bar 33 fixed between the two cross bars, wherein the second cross bar 32 is used to be rotatably connected with the bicycle frame (the second cross bar 32 can be set as Shaft rod, the shaft sleeve that is connected with the shaft rod is placed outside the shaft rod, so that the shaft slee...

Embodiment 2

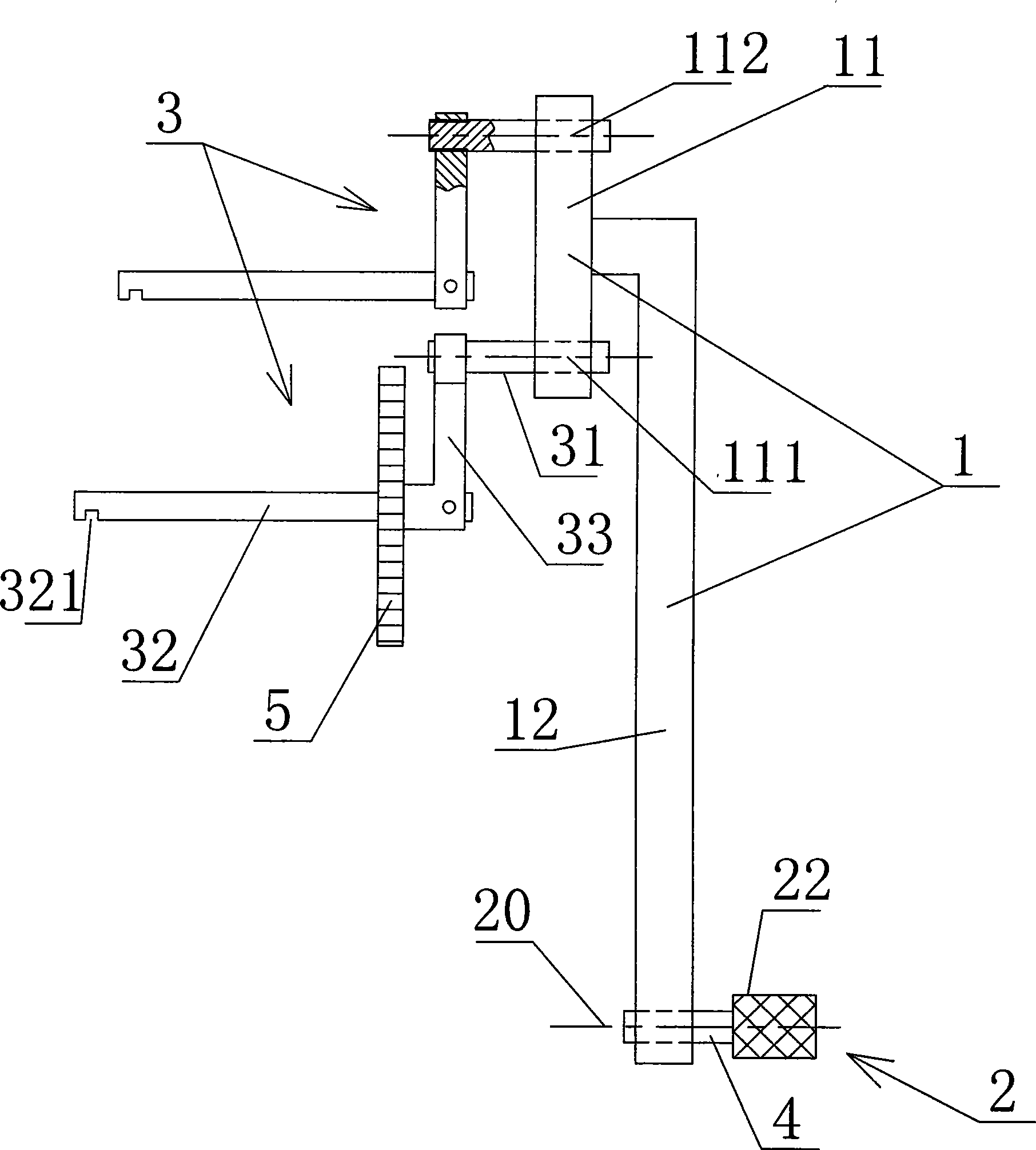

[0022] Such as figure 2 As shown, the difference between Embodiment 2 and Embodiment 1 is that the pedal or the handle 22 is directly connected to the outer end of the power end connecting rod 4 in rotation, instead of being connected with the power end connecting rod 4 through the swing arm 21 .

Embodiment 3

[0024] Such as image 3 As shown, the difference between embodiment 3 and embodiment 1 is that the pedal or handle device 2 is connected to the power rod 12 through the power end connecting rod 4, and the pedal or handle device 2 is only connected to the power end connecting rod 4 A pedal or handle 22 at the outer end constitutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com