Materiel scale

A material and weighing technology, applied in the direction of weighing, instruments, etc., can solve the problems of low weighing accuracy, inaccurate weighing, high tare weight, etc., to ensure the weighing accuracy, prevent the influence of weighing accuracy, Mitigates the effects of low weighing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

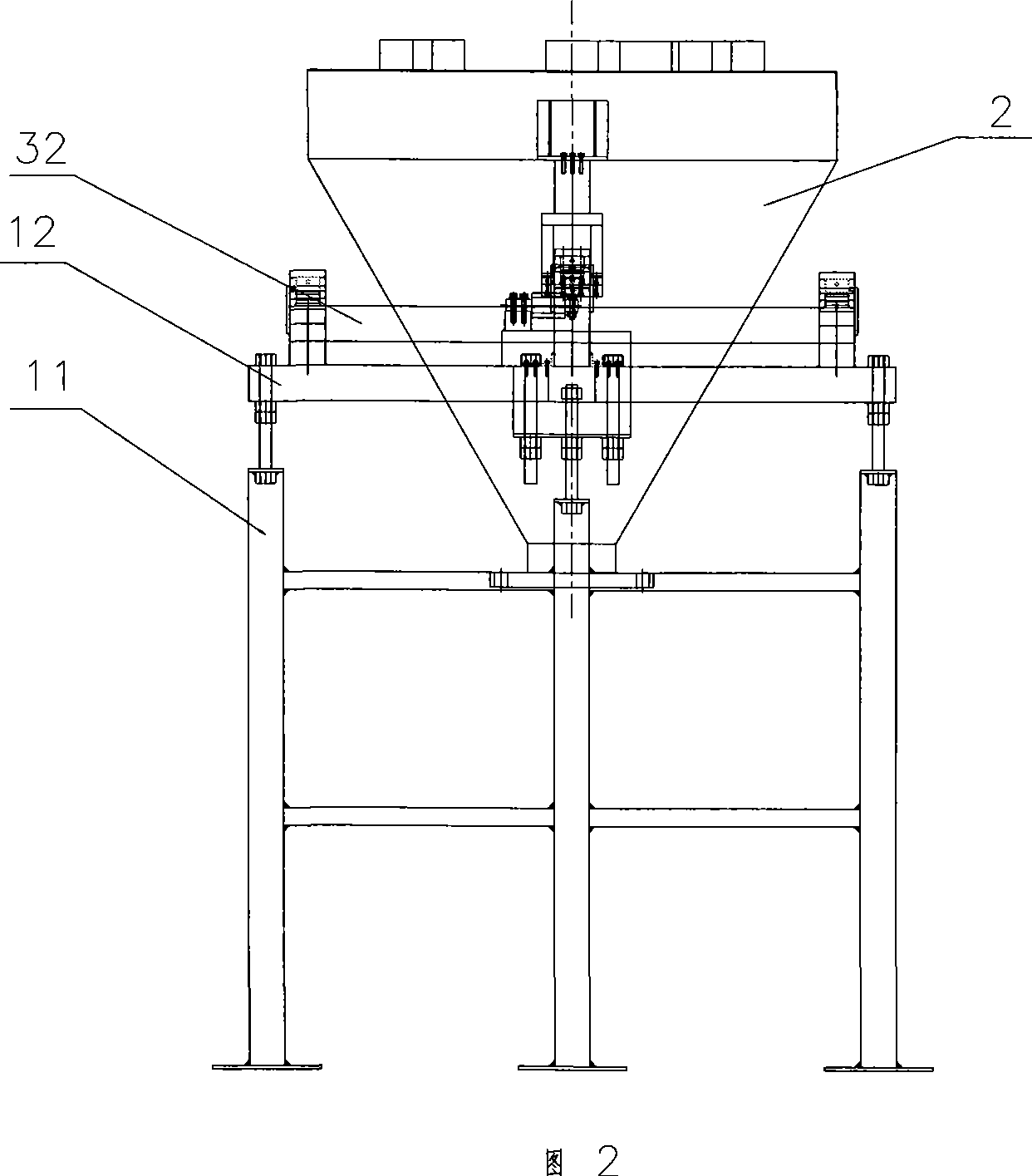

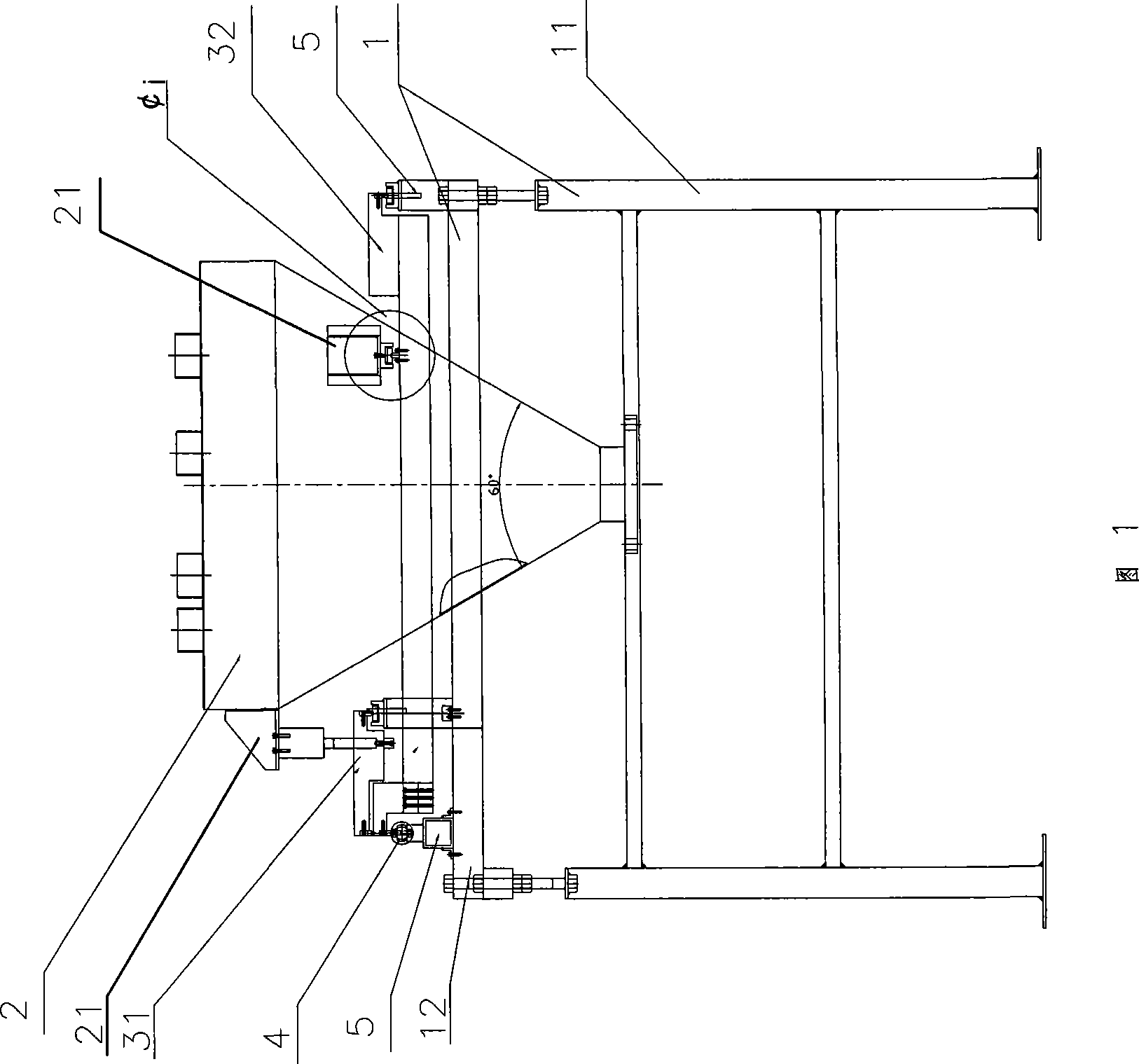

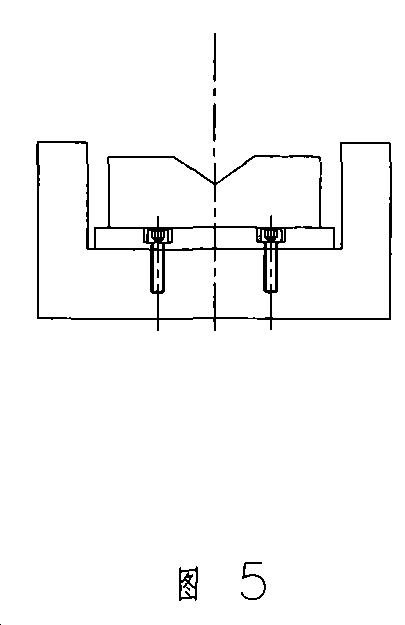

[0015] As shown in Figures 1, 2, 3, 4 and 5, the material scale of the present invention includes a support 1, a hopper 2 and a load cell 4, wherein the support 1 is provided with a weighing module support 5, a weighing support 31 and a scale Heavy bracket two 32, the heavy module support 5 is fixedly connected with the bracket 1, the load cell 4 bears pressure on the weighing module support 5, the left end of the weighing bracket one 31 is supported on the bracket 1, and the right end is supported on the load cell 4 , the left end of the weighing bracket 2 32 is supported on the bracket 1, and the right end is supported on the load cell 4. The left ends of the above-mentioned weighing bracket 1 31 and weighing bracket 2 32 are all provided with protrusions, and the corresponding positions of the bracket 1 are provided with protrusions. There are grooves corresponding to the protrusions, the hopper 2 is provided with three lugs 21, the left lug 21 is supported on the weighing b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com