Dual-purpose reaction desulfuration method and system with calcium-base absorbing agent

A calcium-based absorbent and desulfurization system technology, applied in separation methods, chemical instruments and methods, and dispersed particle separation, can solve the problems of unfavorable desulfurization reactions, low desulfurization efficiency, and high cost, and achieve improved desulfurization efficiency and utilization. , cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

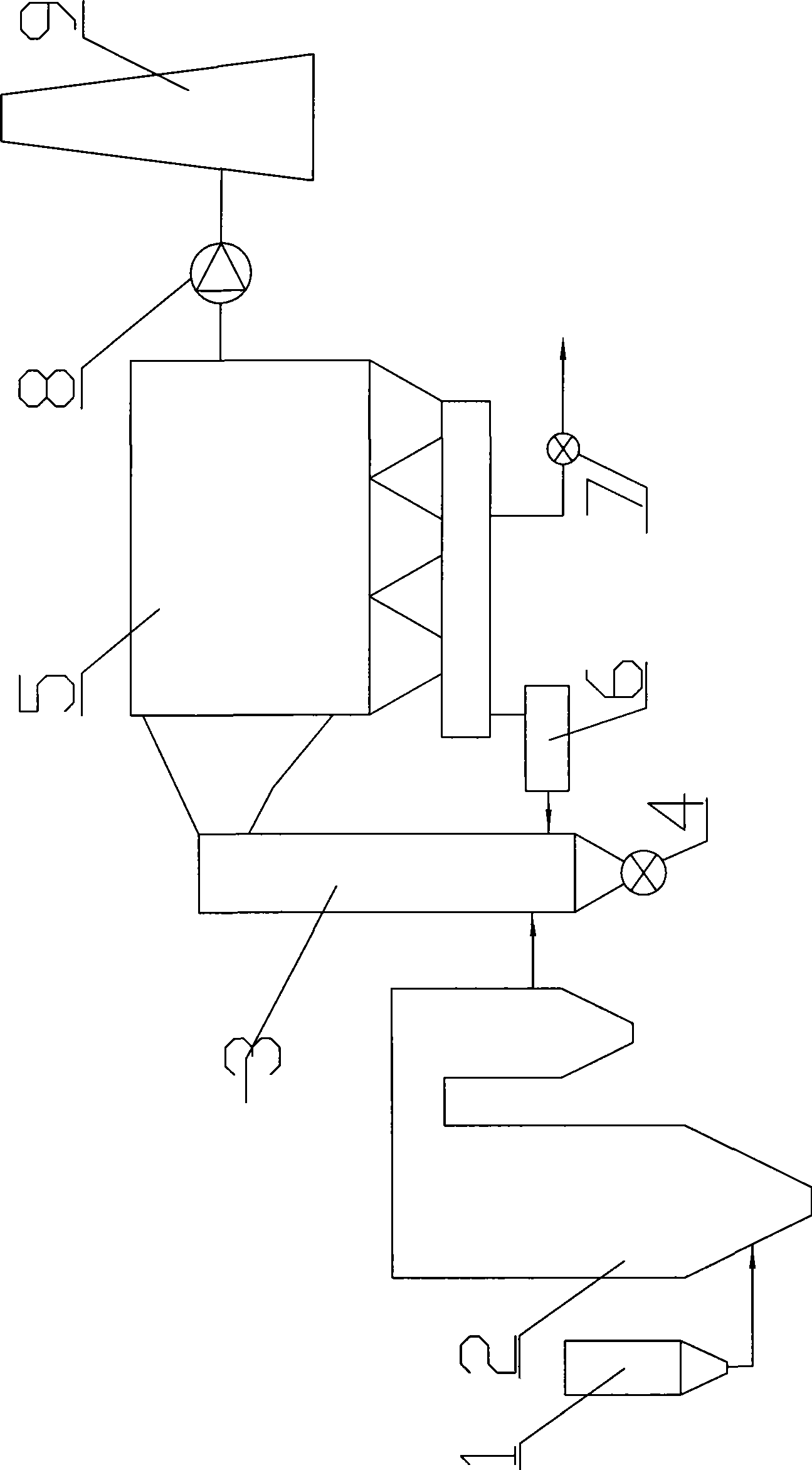

[0018] refer to figure 1 , a calcium-based absorbent double-effect reaction desulfurization system, including a boiler 2, a reactor 3, a dust collector 5, an induced draft fan 8 and a chimney 9 connected in sequence, the boiler 2 is connected with an absorbent adding device 1, and the dust collector 5 is connected with a conditioner 6, the outlet of the conditioner 6 is connected to the reactor 3, the lower part of the reactor 3 is provided with an abnormal ash discharge mechanism 4, and the bottom of the dust collector 5 is also provided with an ash discharge system 7 , A dust discharge valve with metering function is set between the dust collector 5 and the conditioner 6 .

[0019] Calcium-based absorbent double-effect reaction desulfurization method, adding calcium-based absorbent to the boiler through the absorbent adding device, the calcium-based absorbent decomposes into CaO at a high temperature of 800-1000°C and realizes gas-solid desulfurization reaction to generate C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com