Method for producing soya-bean milk and rice paste using full automatic soybean milk machine

A soymilk machine, fully automatic technology, applied in applications, dairy products, household appliances, etc., can solve problems such as the phenomenon of paste electric heating tubes, and achieve the effect of preventing paste electric heating tubes and better taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

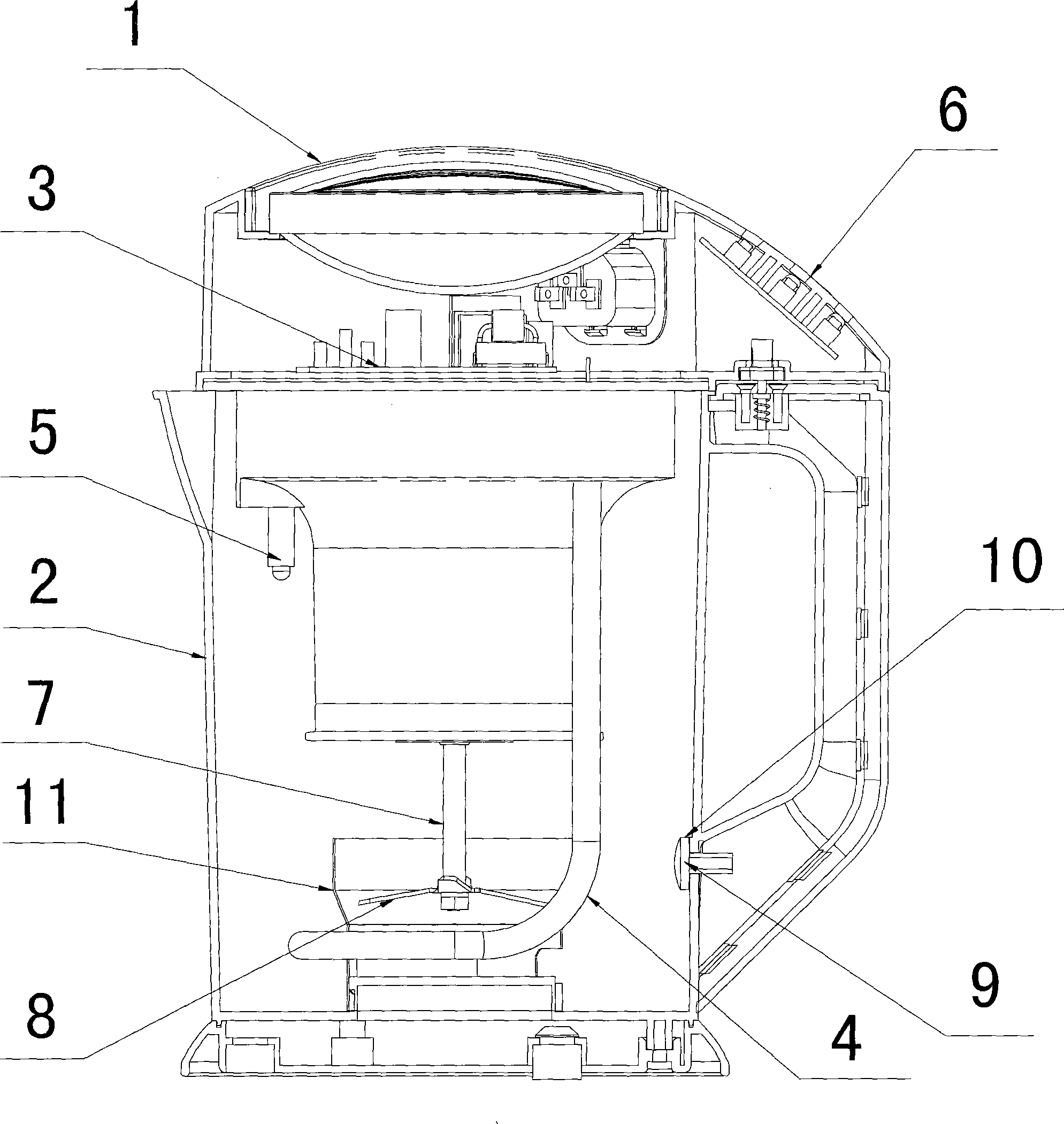

[0019] Embodiment: the present invention uses the method for making soya-bean milk and rice paste with full-automatic soya-bean milk machine, is attached to existing full-automatic soya-bean milk machine and realizes, and the structure of this full-automatic soya-bean milk machine is as follows figure 1 As shown, it mainly includes a machine head 1 and a cup body 2 interlocked with each other. The machine head 1 is provided with a control circuit board 3 and a motor electrically connected to the control circuit board 3, an electric heating tube 4, an anti-overflow electrode 5, and a button. Panel 6 and sounding alarm; fixed rotary blade 8 on the motor spindle 7, signal indicator light is provided on the button panel 6 simultaneously; A firing electrode 10; and a spoiler cup 11 is usually provided at the bottom of the cup body 2, and the rotating blade 8 extends into the spoiler cup 11.

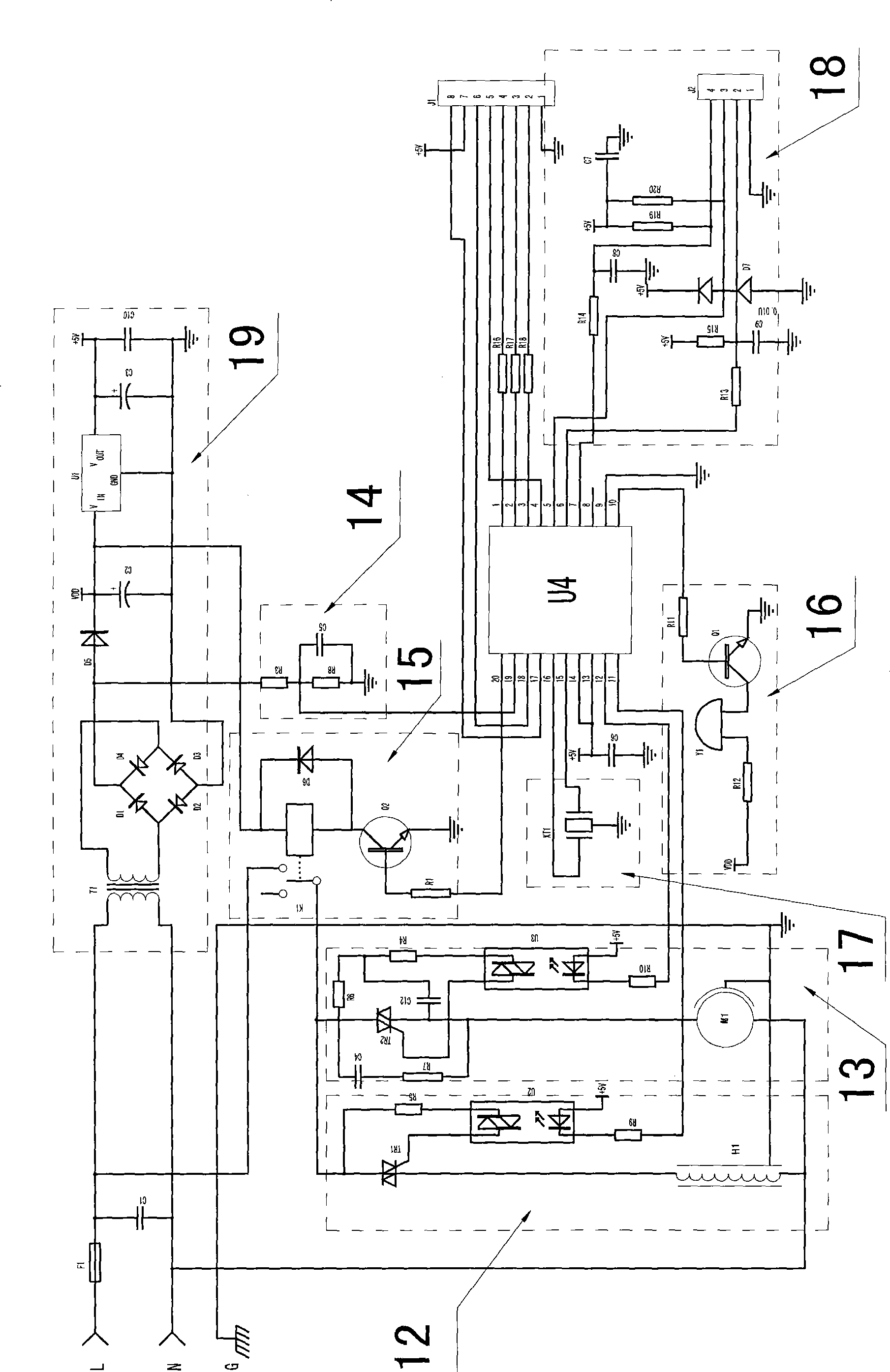

[0020] And the circuit composition of the control circuit board in this automatic soybean ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com