Roping method and apparatus

A cable and collection container technology, applied in the field of cable collection devices, can solve the problems of easy maintenance, dust and grease easily dirty the room, size change, etc., and achieve the effect of ergonomics, simple and cheap implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

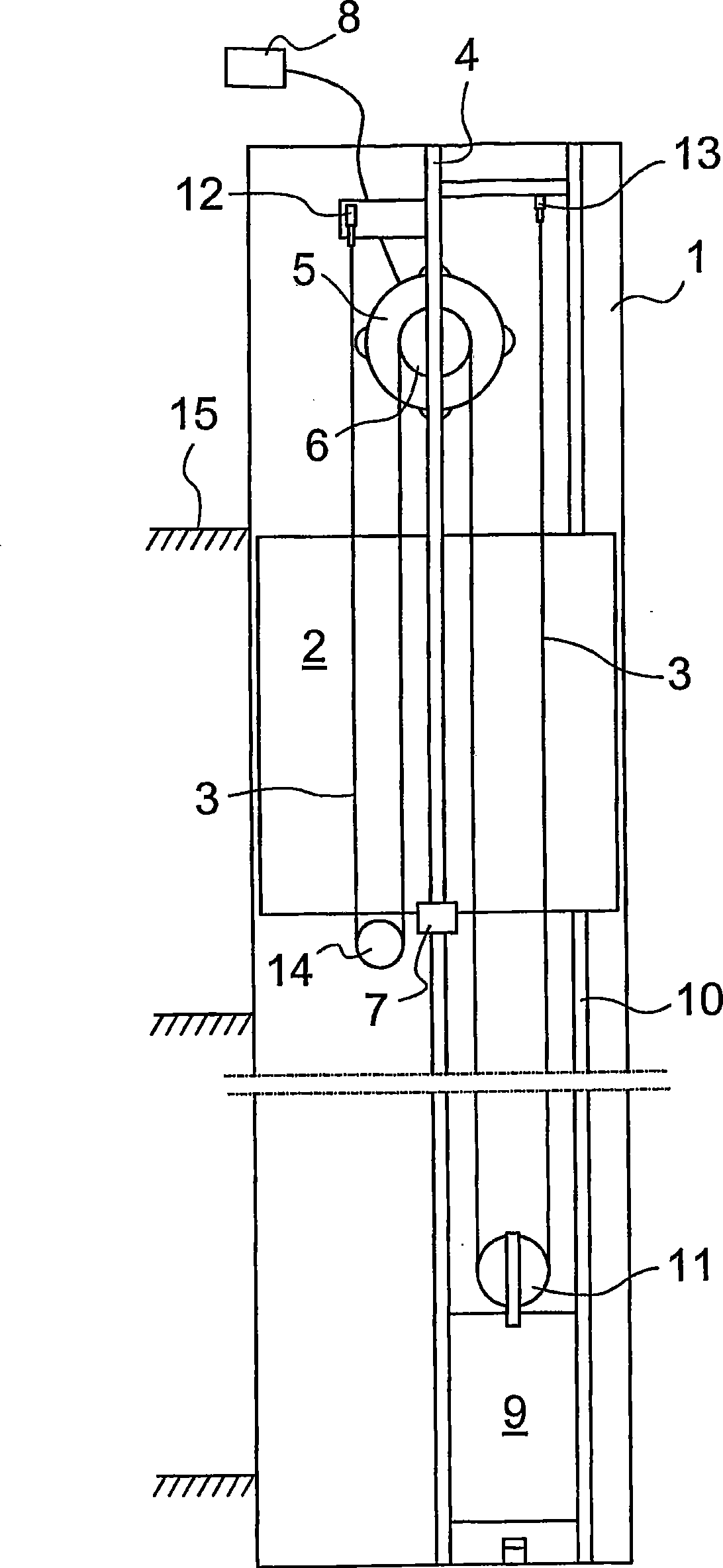

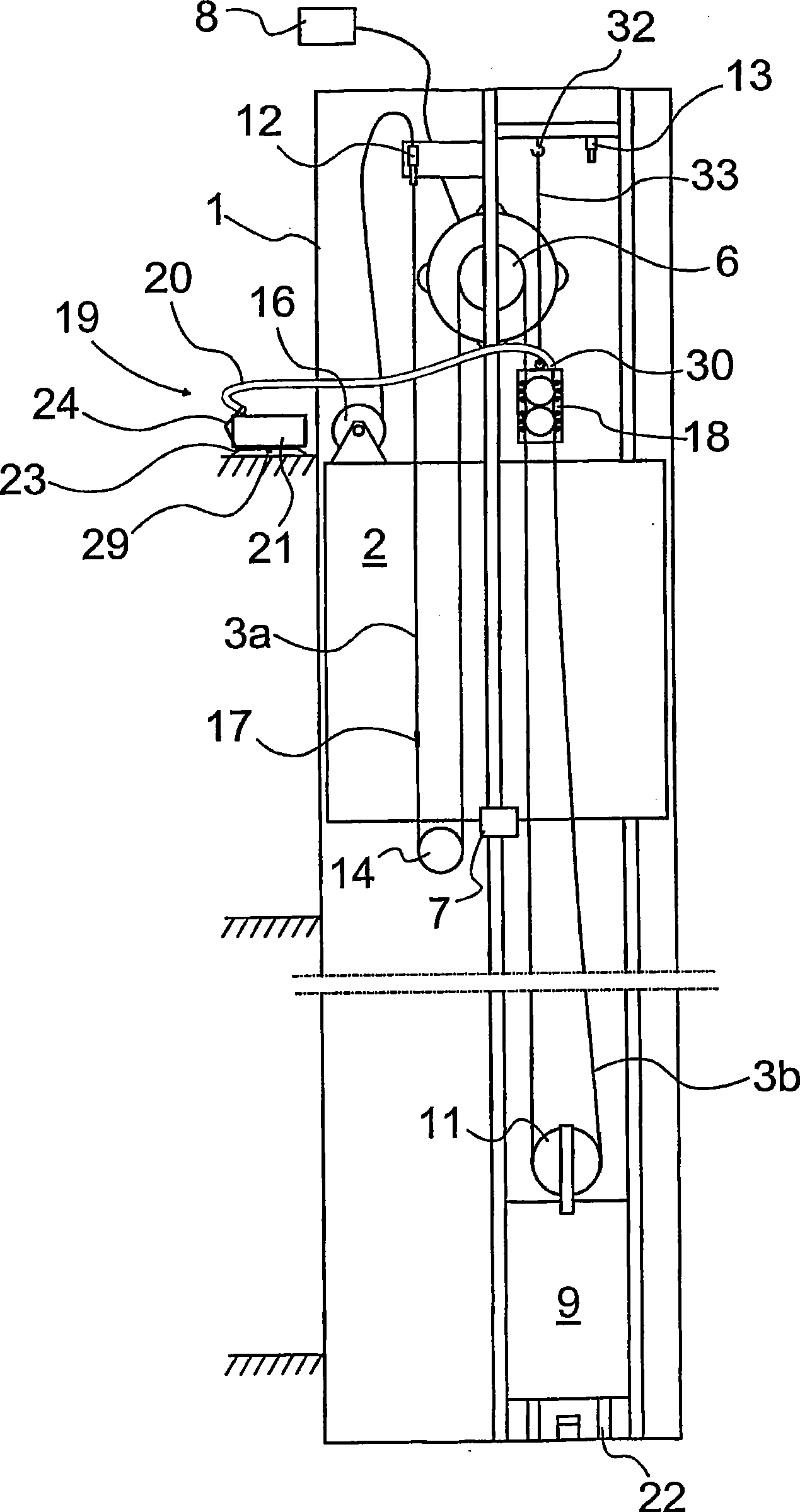

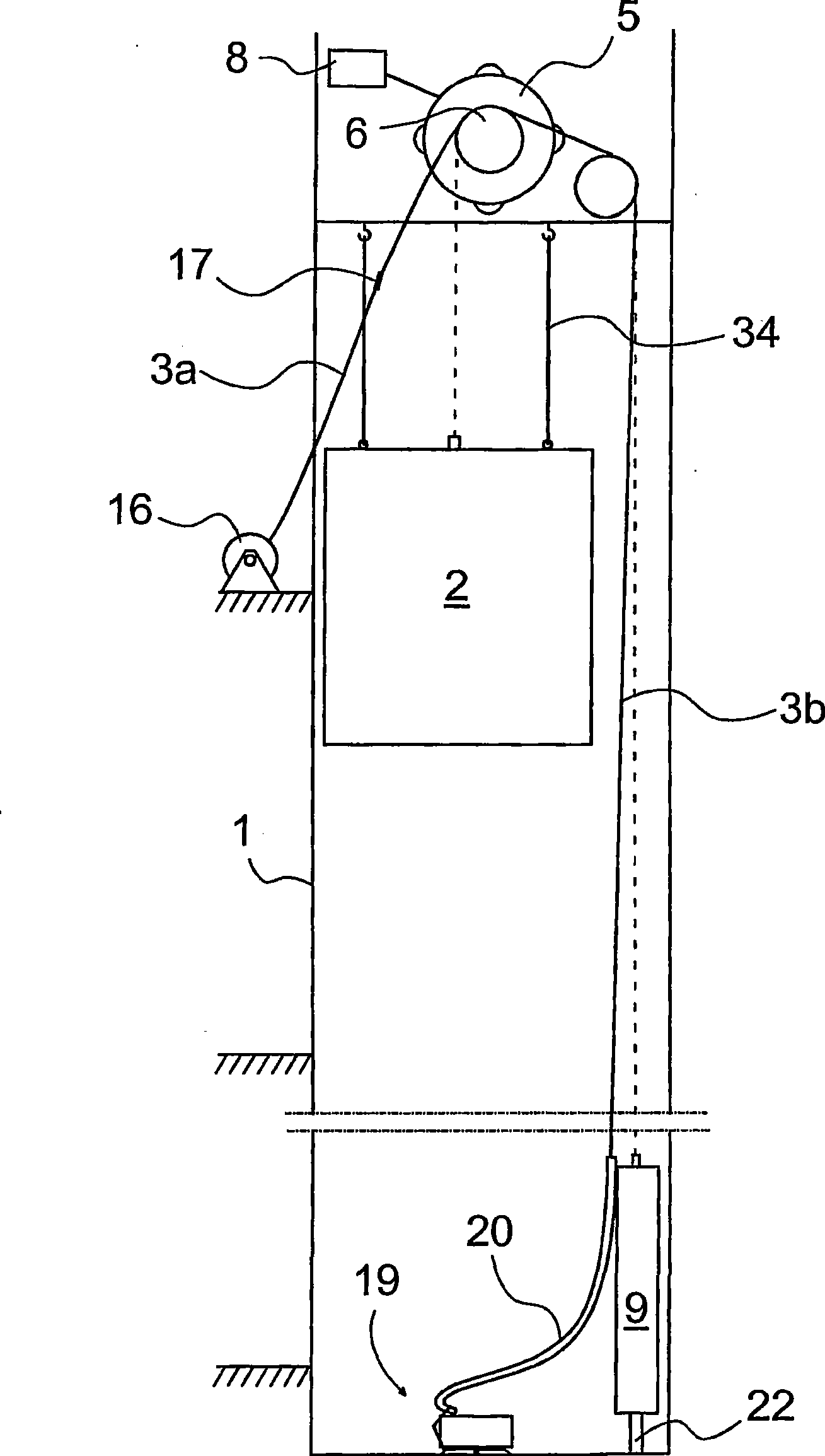

Method used

Image

Examples

Embodiment approach

[0046] According to one embodiment, instead of using a tubular guide element, the guide element can at least partially have a shape other than tubular. In this case, the guide element can be groove-shaped, for example, so as to be guided with the cable along the bottom and side walls of the groove of the guide element into the collecting container. The collection container can also be a basket or the like, or a temporary container constructed in a frame, for example a container with a detachable bottom or frame edge parts that can be bent inwards.

[0047] Figure 5 A schematic diagram is shown of the cable pulling device 18 of the present invention. The cable pulling device of the cable collecting device according to the invention is based on frictional pulling and is realized by pressing one or more two-part pulling disks with the desired spring force so that the disks 38, 39 are pressed against each other. The shape of the discs 38, 39 is such that the cables run as far a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com