Articulated probe

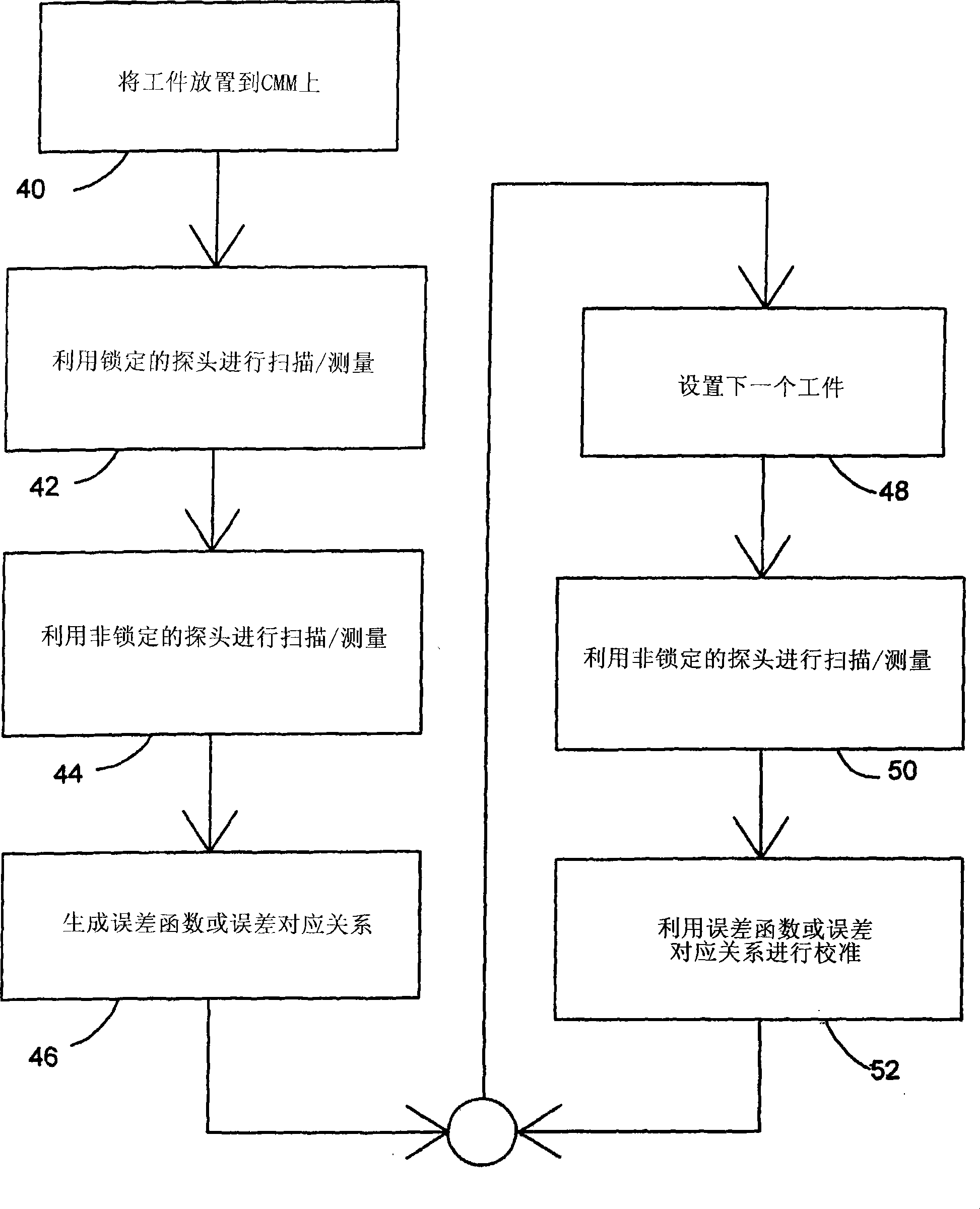

一种铰接式、接触点的技术,应用在点坐标测量、测量装置、仪器等方向,能够解决校准耗时、校准复杂等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

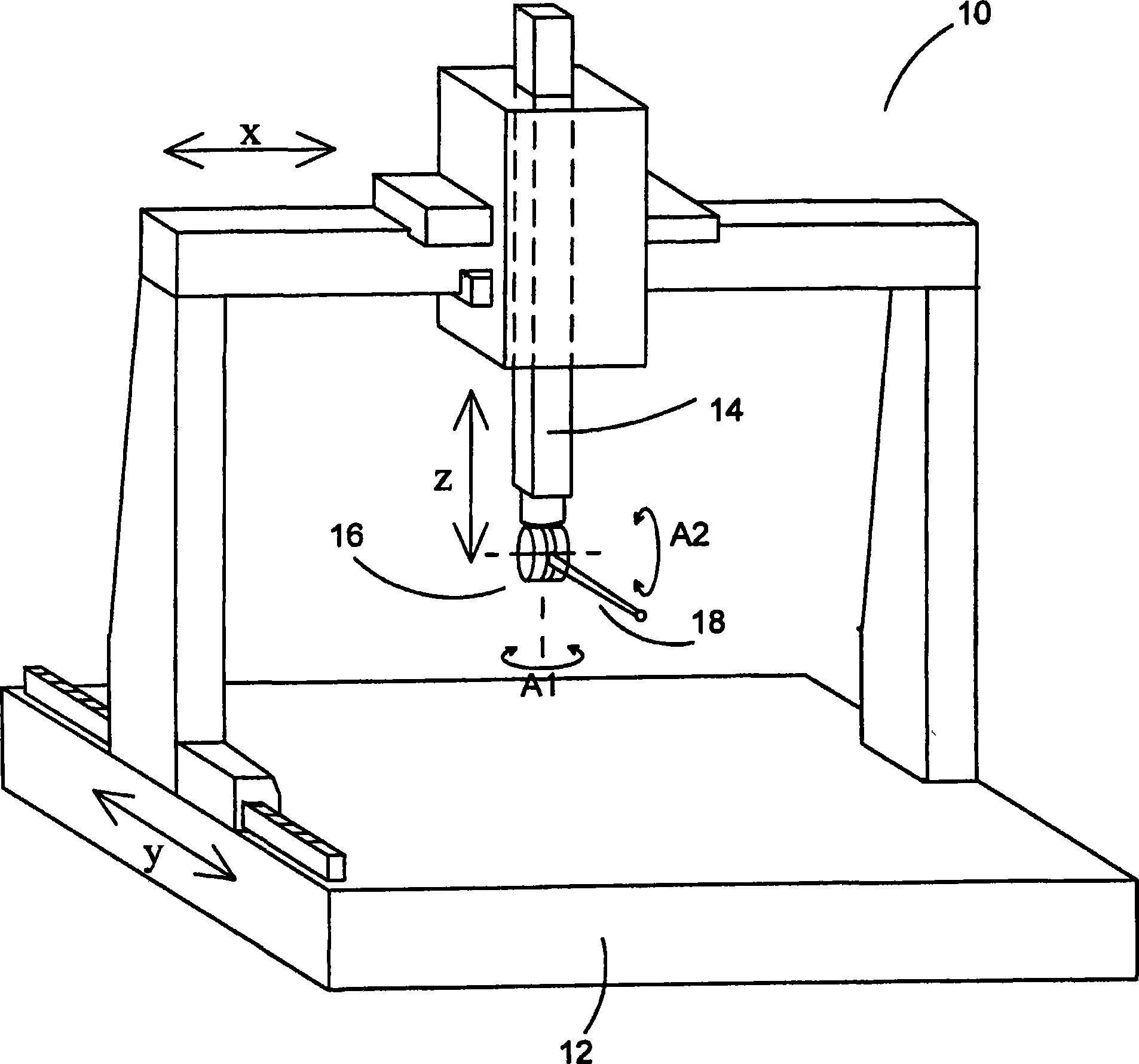

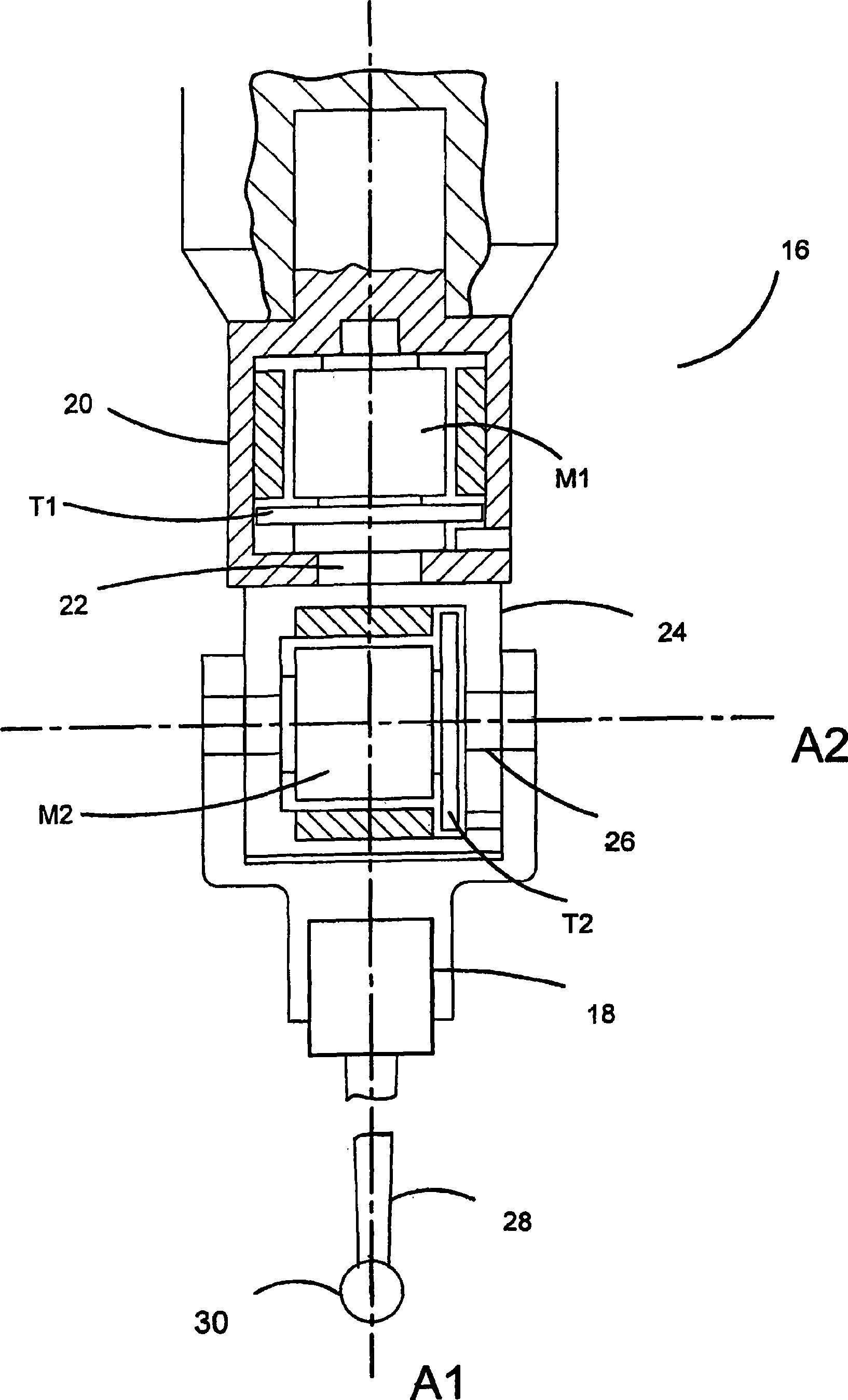

[0045] figure 1 Shown is the articulated probe mounted on the coordinate measuring machine. The coordinate measuring instrument 10 includes a platform 12 on which a workpiece can be placed and an arm 14 movable in X, Y, and Z directions relative to the platform 12. The articulated probe 16 is mounted on the arm 14 of the coordinate measuring machine (CMM). The articulated probe 16 allows the workpiece measuring probe 18 mounted thereon to rotate about two substantially vertical axes A1 and A2.

[0046]Therefore, the robot arm 14 can move in the X, Y, and Z directions under the action of the X, Y, and Z driving devices (not shown) of the coordinate measuring instrument. The scale devices (not shown) on X, Y and Z display the real-time coordinates of the position of the arm 14. A rotation drive device (not shown) located in the articulated probe can make the probe move around the two rotation axes A1 and A2. This movement is measured by a rotating scale device (not shown) located ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com