Dual-rotated counterweight type automatic horizontal regulation sling system

A technology of level adjustment and automatic adjustment, applied in the direction of load hanging components, transportation and packaging, can solve the problems of drastic changes in the included angle, difficult to achieve accuracy, difficult to guarantee accuracy, etc., achieve simple mechanical structure, improve installation efficiency, simplify The effect of the installation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] The present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that the described embodiments are only intended to facilitate the understanding of the present invention, rather than limiting it in any way.

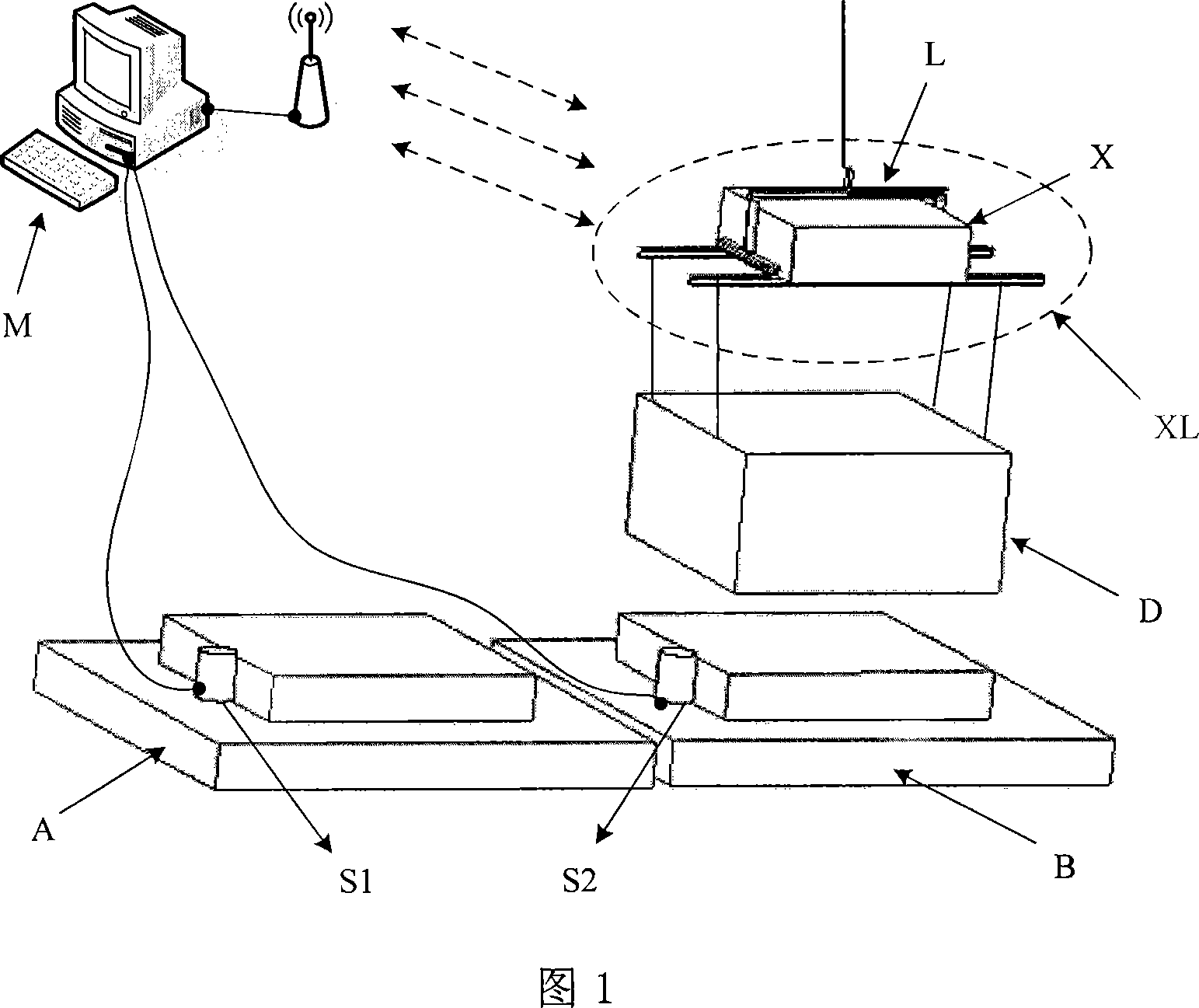

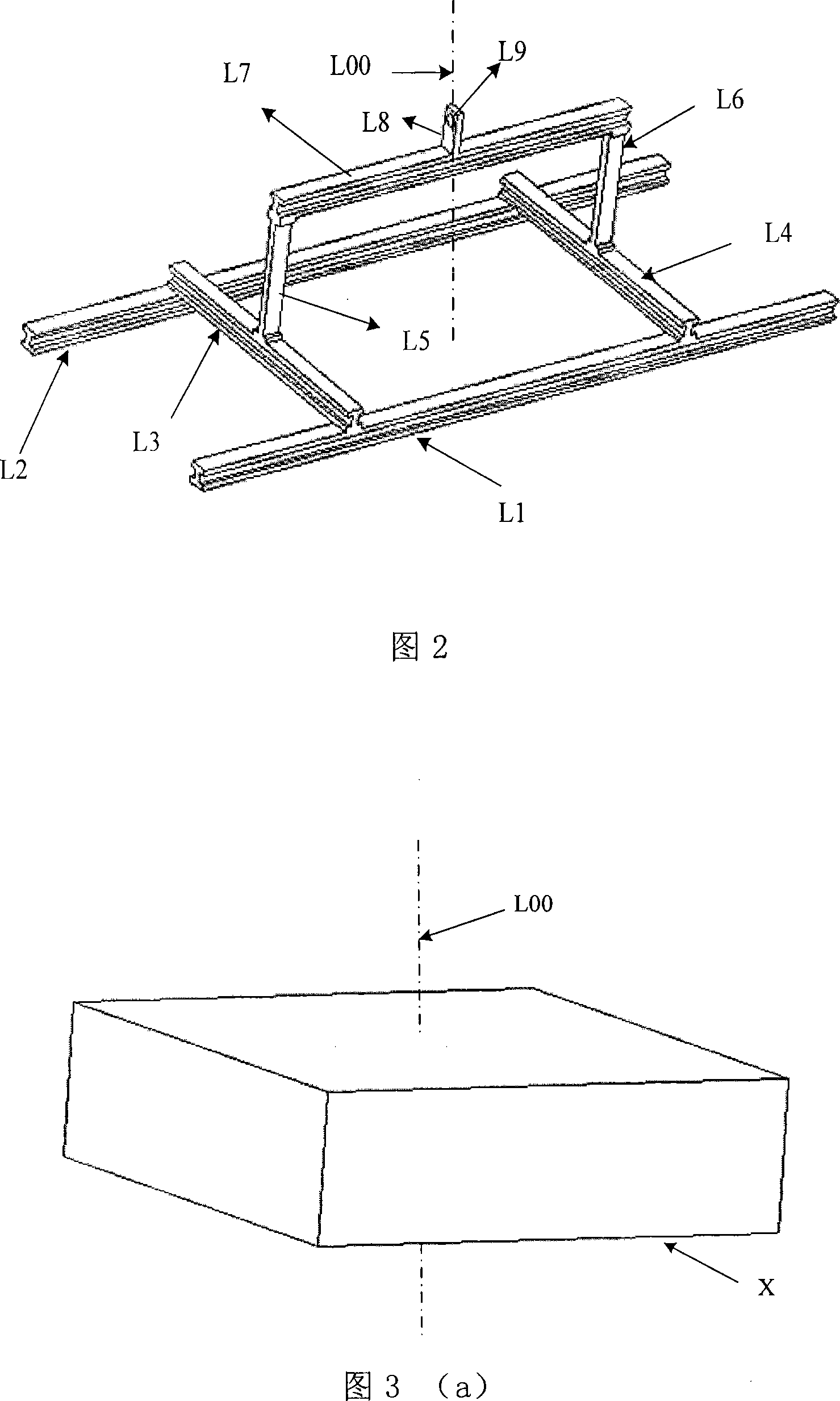

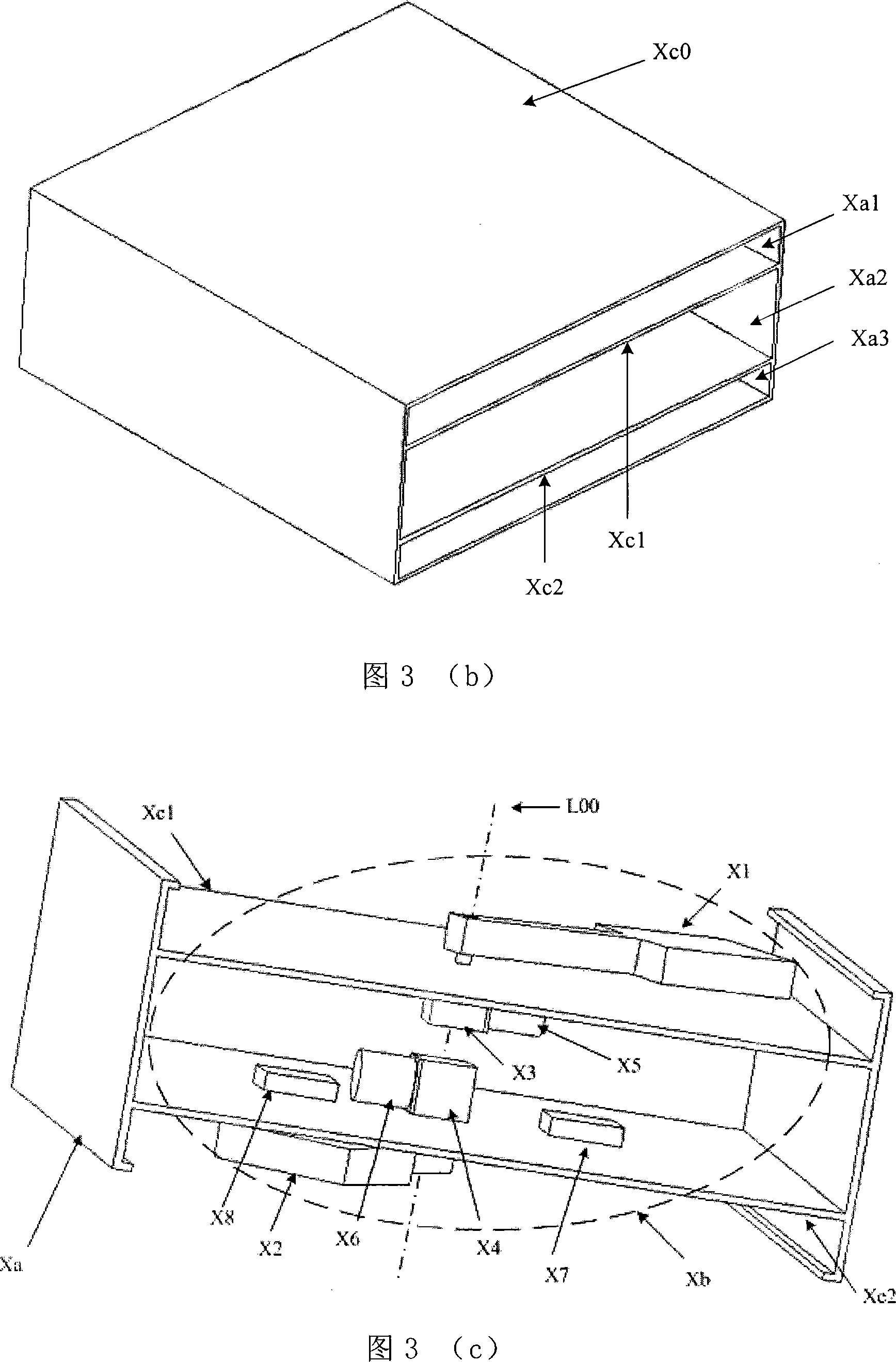

[0074] The implementation example of the present invention is aimed at the high-precision hoisting of precious and vulnerable loads. The overall structure of the spreader system of the present invention can be divided into four major parts: as shown in the schematic diagram of the overall mechanism of the system in Figure 1: computer M, load-bearing spreader L, Automatic level adjustment of the box X, and the first bottom surface angle sensor S1 and the second bottom surface angle sensor S2. The hoisting task is to hoist the load D to be hoisted from the first platform A to the second platform B, while keeping the bottom surface of the load D level. The spreader system realizes the function of adjusting and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com