Method and equipment for digitized detection of double-plain shaft parallelism of optical instrument

An optical instrument and parallelism technology, applied in the direction of instruments, optical devices, measuring devices, etc., can solve the problems of large workload, long operation time, low detection and correction accuracy, etc., to reduce workload, improve accuracy, The effect of shortening the operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

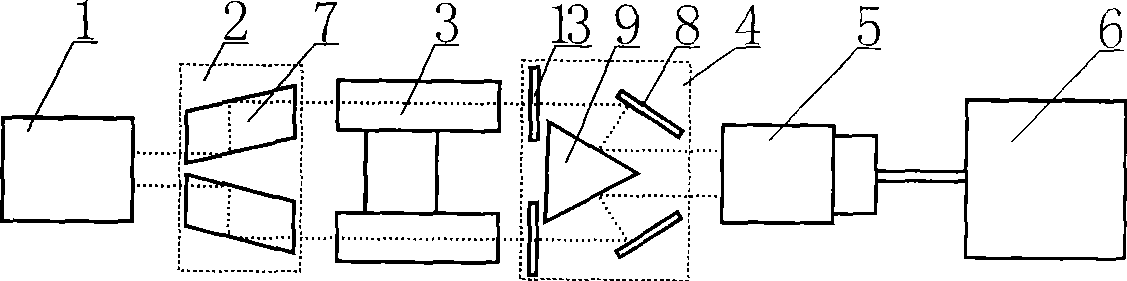

[0022] like figure 1 As shown, a method for digitally detecting the parallelism of dual optical axes in an optical instrument comprises the following steps:

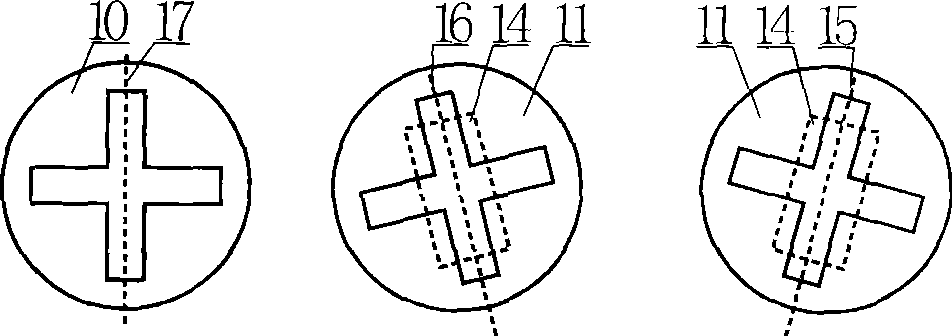

[0023] a. Divide the parallel light in the shape of a "cross" emitted by the collimator 1 into two beams of strictly parallel light through the beam splitter 2, and present two original "cross"-shaped images 10 horizontally, flat and vertically.

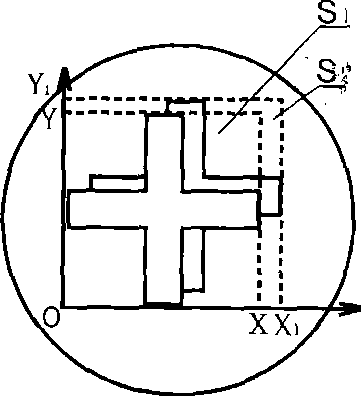

[0024] b. Two beams of strictly parallel light presenting two horizontal, flat and vertical original "cross"-shaped images 10 are injected into the objective lenses in the two light tubes of the optical instrument 3 under test, and projected from the eyepiece to present a "cross"-shaped image 11 After the emitted light, the two beams of light present a "cross"-shaped image 11 containing information about the parallelism of the two optical axes of the instrument under test.

[0025] c. Combining the light of the "cross"-shaped image 11 of the two optical axis parallelism inform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com