Power supply method and apparatus for large-sized multifunctional overhead travelling crane

The technology of a power supply method and power supply device is applied in the direction of transportation and packaging, load suspension components, etc., which can solve the problems of affecting production efficiency, increasing the workload of cable maintenance and overhaul, and fast aging of cable insulation, so as to achieve simple structure and high efficiency. Good power supply capacity and anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiment of the present invention: the power supply of the crane in the prior art adopts the mode of suspension cable power supply, such as Figure 4 shown. Pull up traction steel wire 15 at the two ends of workshop, hang slidable dolly 16 on traction steel wire 15, power supply cable 17 is suspended on dolly 16. Because one end of the cable 17 is connected with the power supply 18 on one side of the factory building, the other end is connected with the distribution box 2 on the crane. The main problems in the prior art are that the amount of cables used is long, the cables are often bent and easily broken, and the accumulation of cables results in a small operating range of the crane.

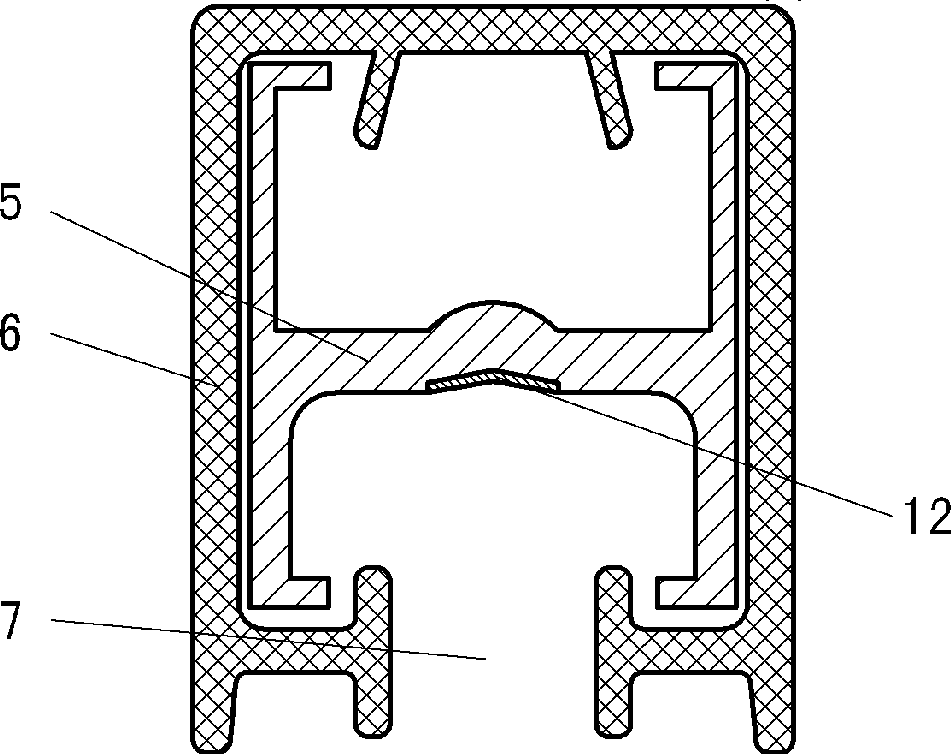

[0018] The power supply method of the large-scale multifunctional overhead crane of the present invention is as follows: figure 1 shown. The method of the present invention is to install the insulated trolley line 4 on the crossbeam 3 running on the crane, the insulated trolley lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com