Perforating device for automatic cloth cutter

The technology of a punching device and a cutting machine is applied in the cutting of textile materials, textiles and papermaking, metal processing, etc. It can solve the problems of inconvenient disassembly, inconvenient disassembly, and low punching accuracy, so as to improve life, reduce wear, Positioning precise effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

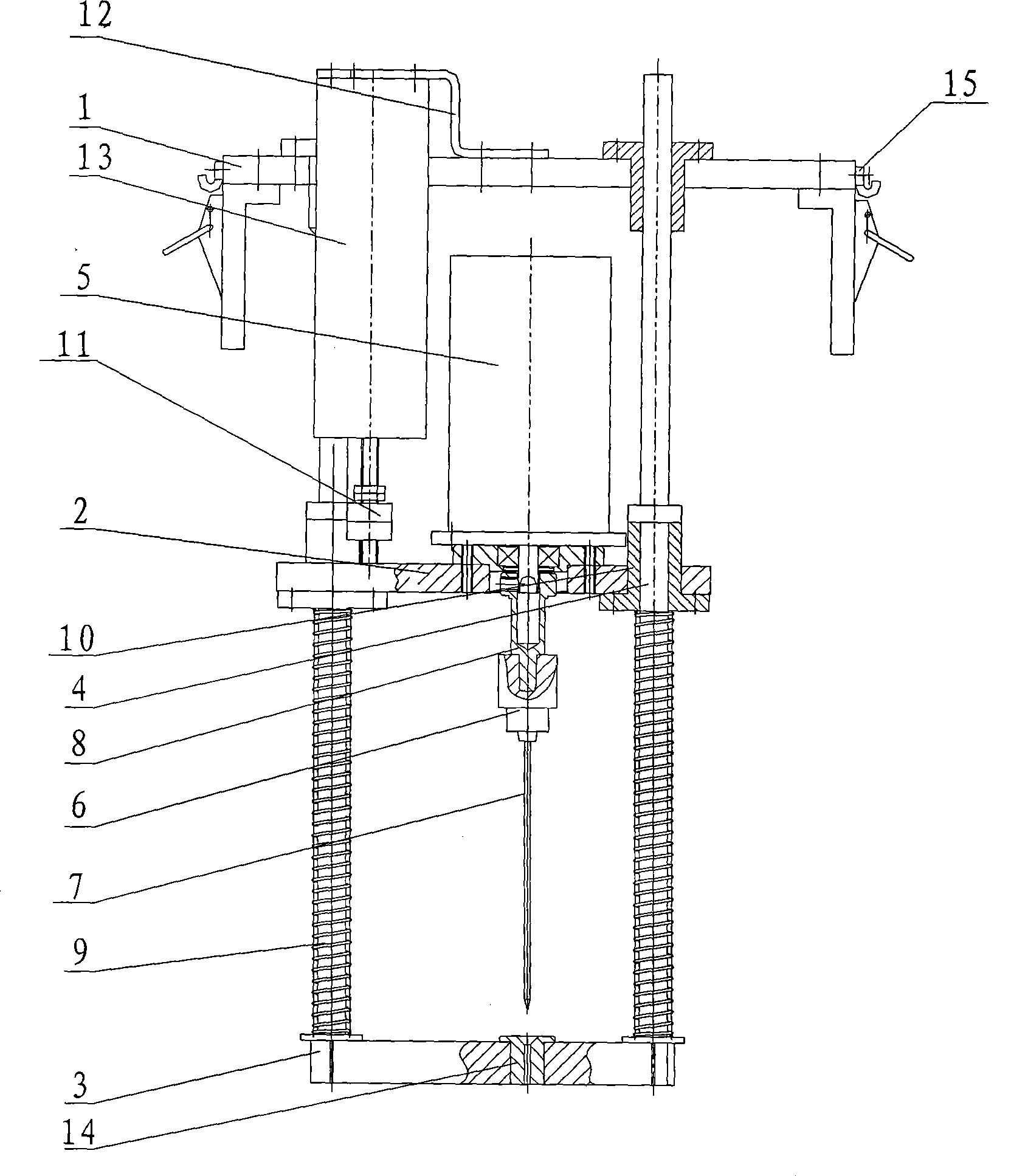

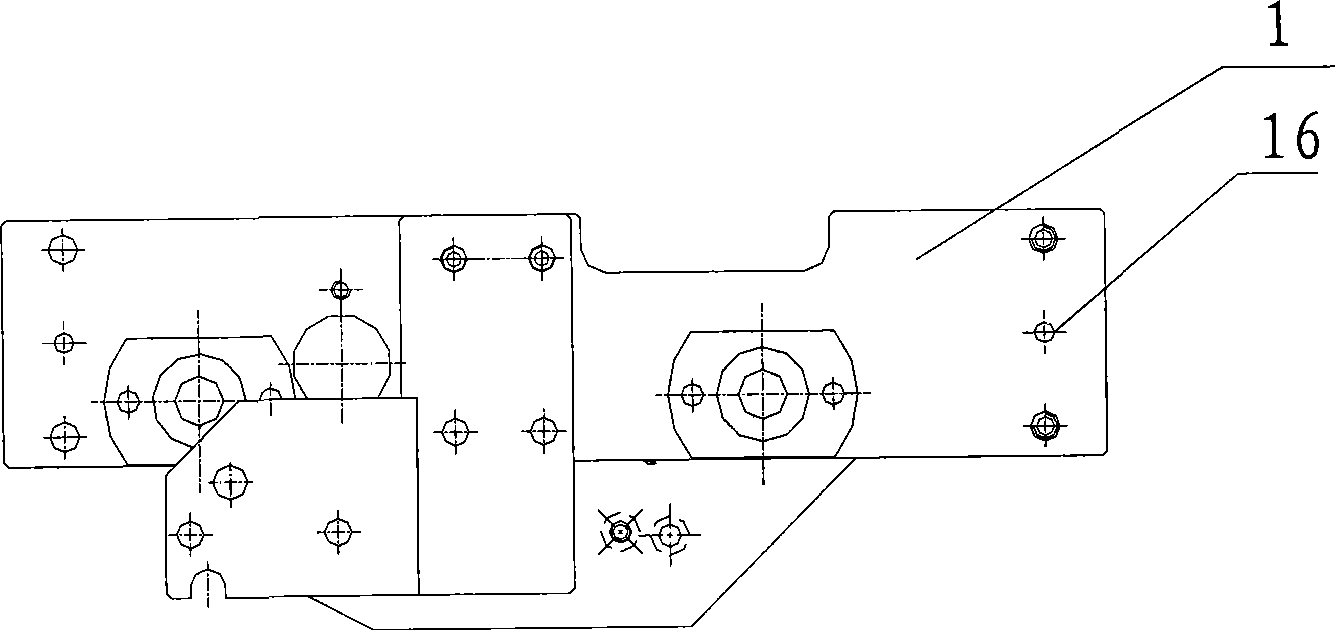

[0020] Such as figure 1 , figure 2 As shown, the present invention is used for the punching device of the automatic cutting machine, comprises the upper plate 1, the middle plate 2 and the lower plate 3 that are horizontally arranged in parallel, and there are two longitudinally running through between the upper plate 1, the middle plate 2 and the lower plate 3. The slide rail shaft 4 arranged in parallel, the motor 5 is arranged on the middle plate 2, the drill chuck 6 and the punching needle 7 are arranged vertically downward, the drill chuck 6 is connected with the motor 5 through the bearing shaft 8, and the middle plate 2 is arranged along the The slide rail shaft 4 slides up and down, and a spring 9 is sleeved on the slide rail shaft 4 between the middle plate 2 and the lower plate 3 .

[0021] There are two linear slide rail seats 10 on the middle plate 2, and the two slide rail shafts 4 respectively pass through the linear slide rail seats 10, and a retaining ring 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com