Wire pair testing drawing board, lens optical parsing and measuring system and measuring method thereof

A test line and resolution technology, applied in the lens optical resolution measurement system and its measurement field, can solve the problems of difficulty in identifying the lens to be measured, no identification, and difficulty in determining the optical axis of the lens, and achieve the measurement value of the optical resolution capability. precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In the following, the test line provided by the present invention will be further described in detail with respect to the drawing board, the lens optical analysis measurement system and the measurement method thereof in conjunction with the accompanying drawings.

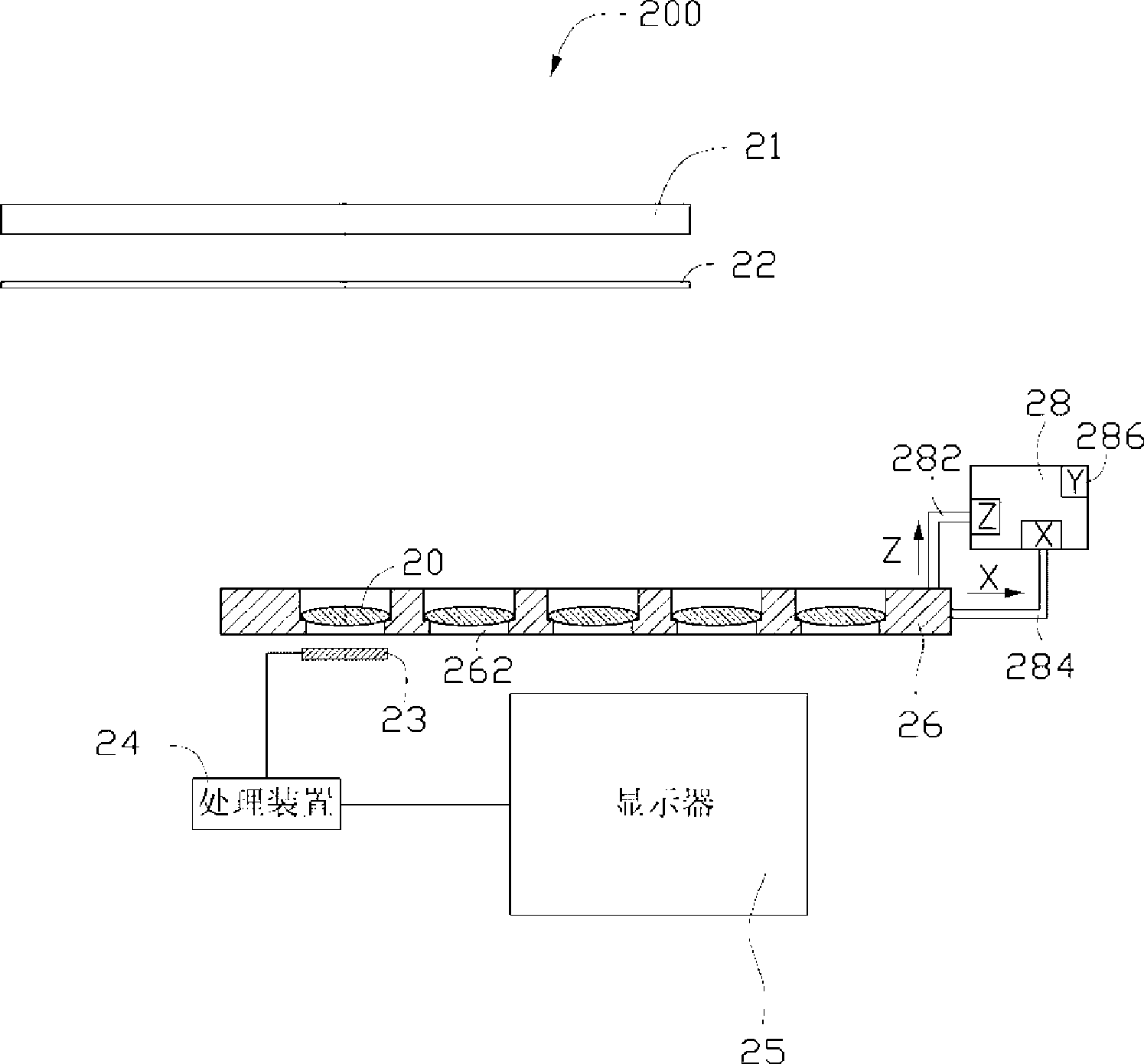

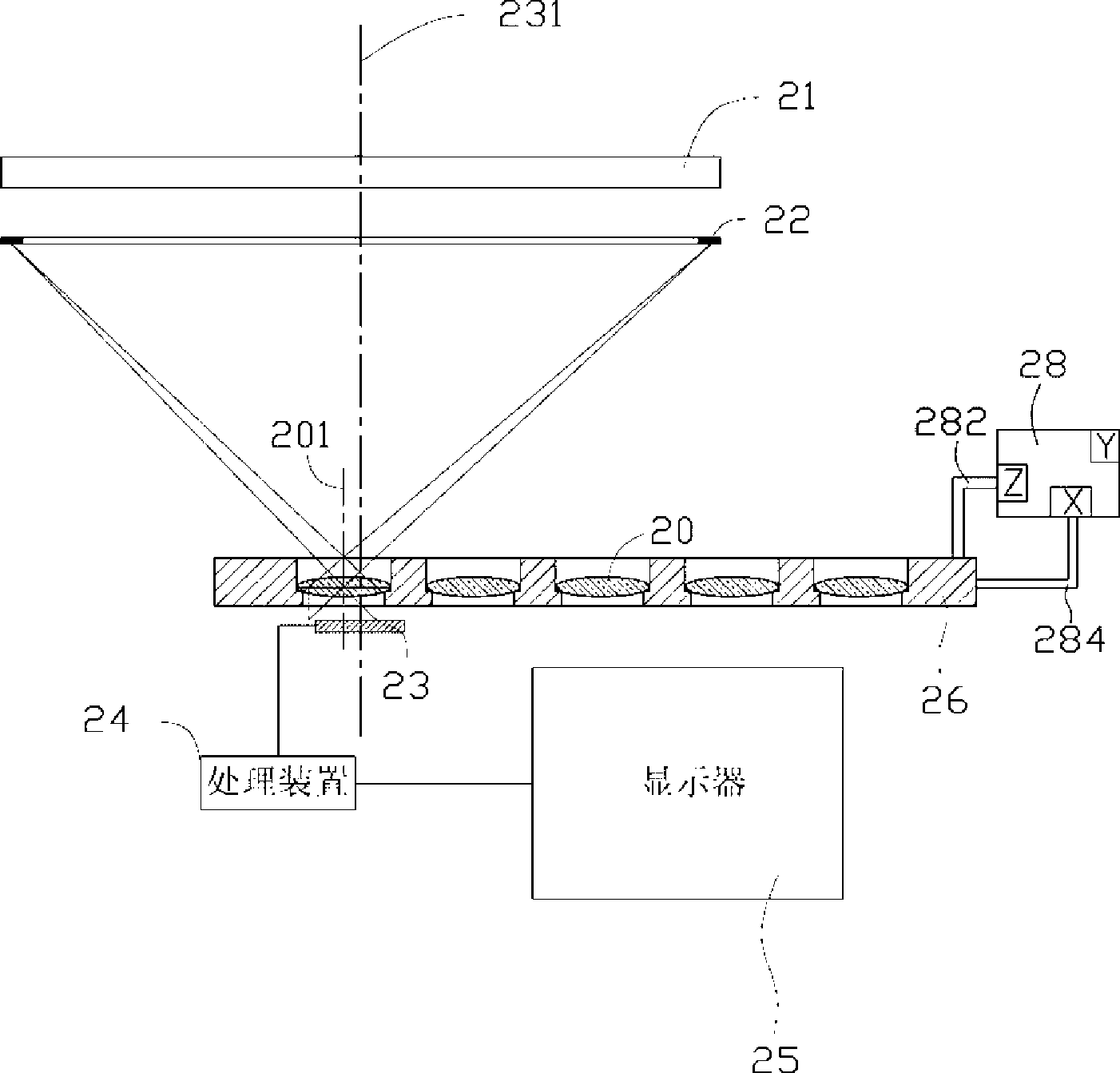

[0018] Please also refer to figure 1 and figure 2 , the lens optical analysis measurement system 200 provided by the embodiment of the present invention includes a light source device 21, a test line pair chart 22, an image sensor 23, a processing device 24, a display 25, a hollow bearing Disk 26 and a drive device 28 for driving the carrier disk 26 .

[0019] The light source device 21 can be an LED device for emitting light to illuminate the test line pattern board 22 .

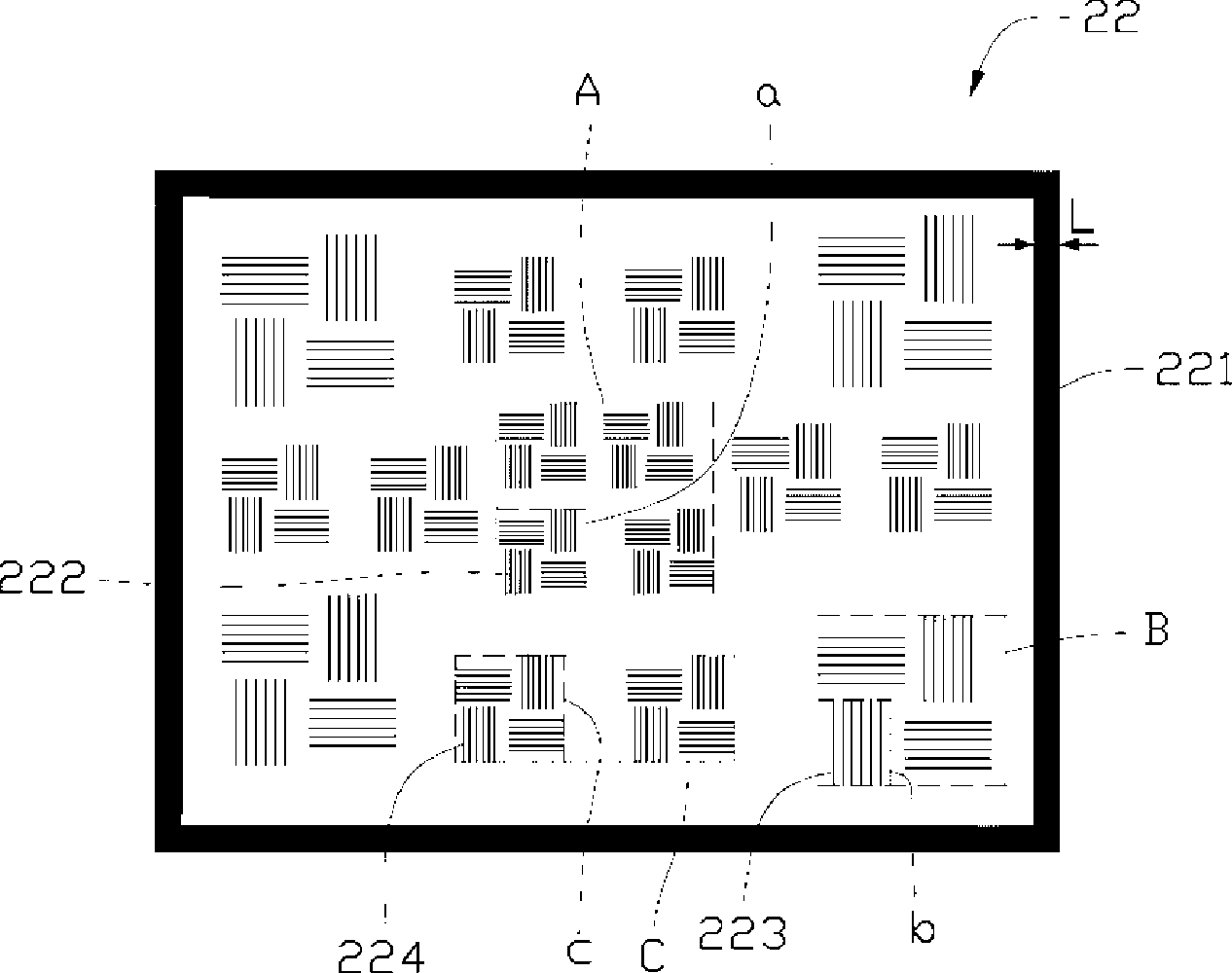

[0020] The test line pair chart 22 has a thickened frame pattern 221 , which is located on the edge of the entire test line pair chart 22 , has a rectangular shape, and is symmetrical about the center of the entire test line pair chart...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com