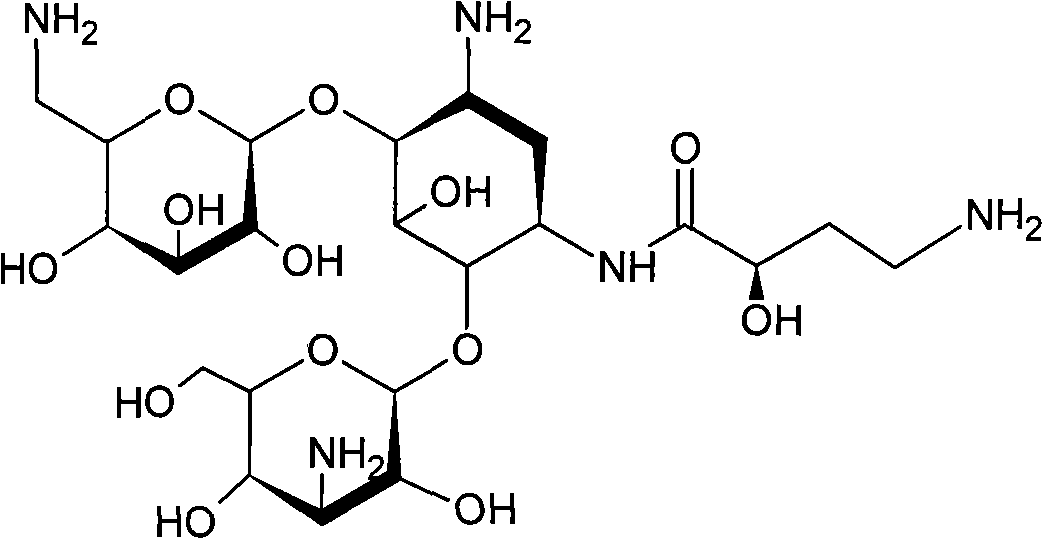

Method for concentrating amikacin desorbed solution using nano filtration technique

An amikacin and analytical solution technology, applied in the application field of amikacin analytical solution concentration, can solve problems such as low retention rate of monovalent inorganic salts, reduce energy consumption, improve product yield and quality, shorten the The effect of reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

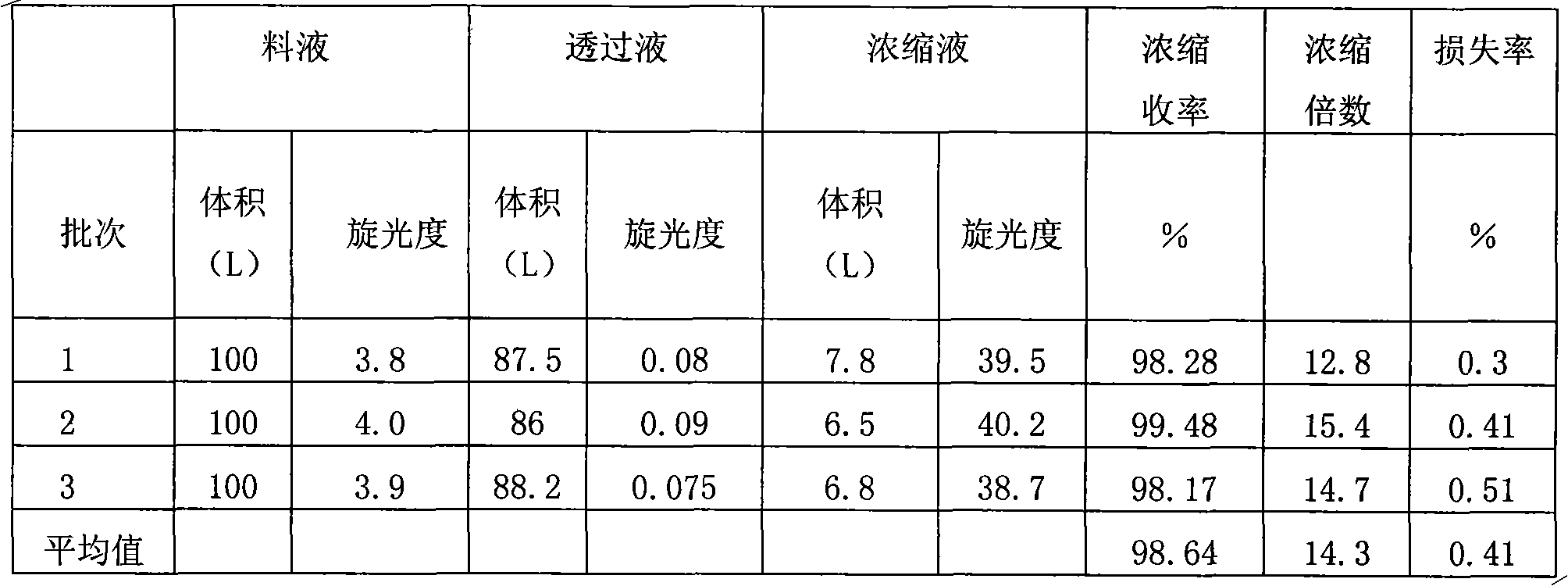

Examples

Embodiment 1

[0035] The feed liquid used in this example is amikacin analysis solution, pH 11.5-12.

[0036] A method for concentrating amikacin analysis solution, the steps are as follows:

[0037] 1. Pre-filtration and purification

[0038] At room temperature, the inlet pressure of the pre-filter system is controlled at 1MPa, and the outlet pressure is 0.8MPa. The material liquid (amikacin analysis solution) is transported into the pre-filter system through the material transfer pump, and the filtered amikacin enters the cleaning system. The liquid storage tank, while the suspended particles are intercepted, and then proceed to the next step of nanofiltration concentration.

[0039] 2. Nano-membrane concentration

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com