Process for dyeing the hair using a composition comprising a hydrophobic film-forming polymer, a pigment and a volatile solvent

A film-forming polymer, volatile solvent technology, used in medical preparations containing active ingredients, hair care, pharmaceutical formulations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

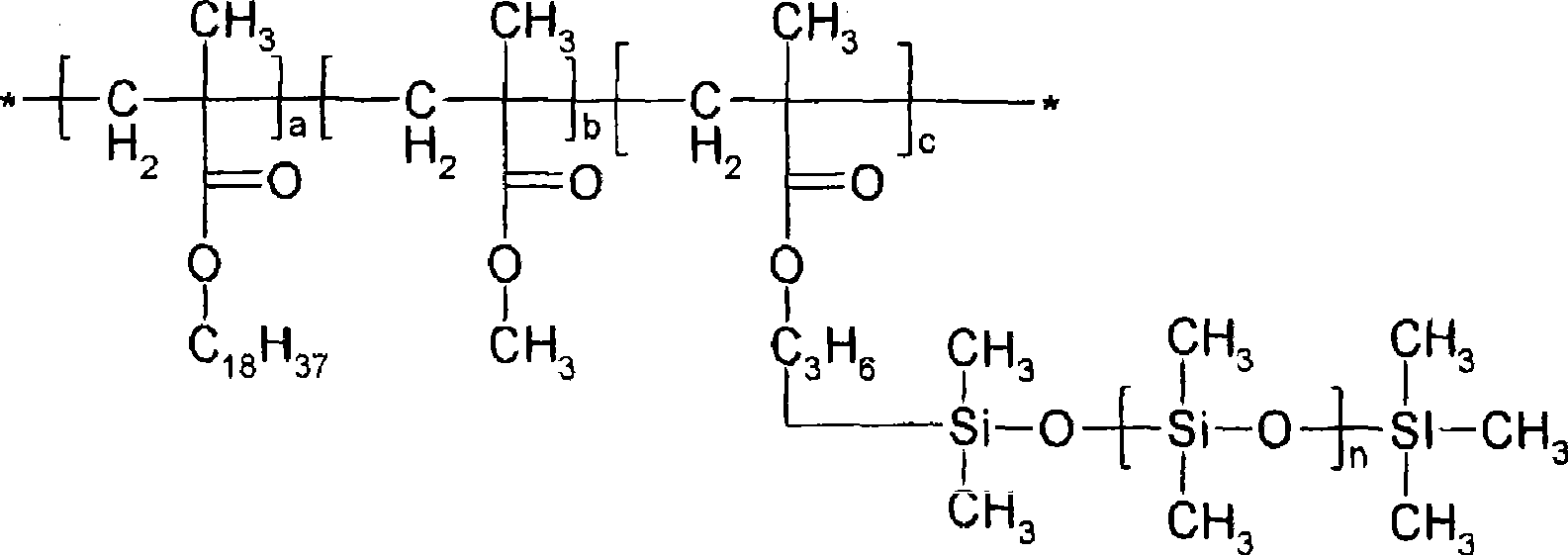

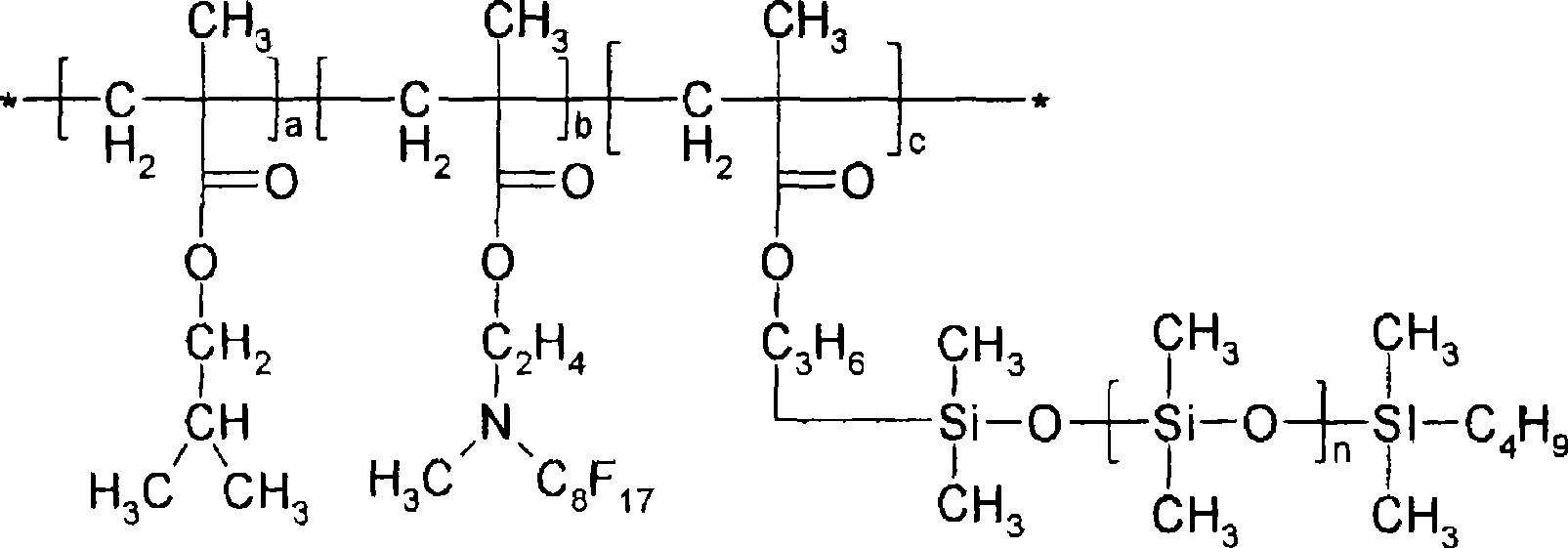

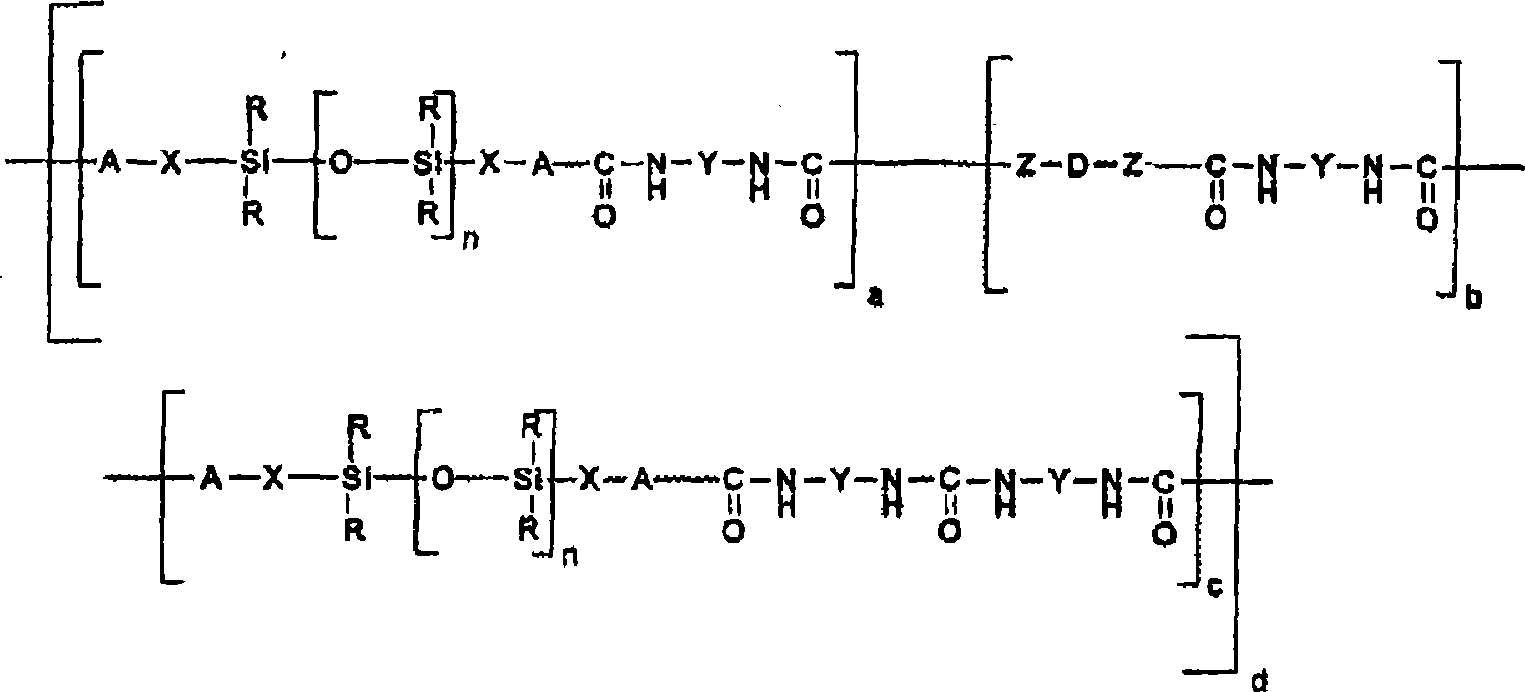

Method used

Image

Examples

Embodiment 1

[0428] Prepare the following compositions:

[0429] Cellulose levulinate sold under the tradename CAB-381-0.5 by Eastman Chemical 10 g

[0430] Mica-iron oxide mother-of-pearl sold under the trade name Prestige Soft Bronze by Eckart

[0431] 10g

[0432] Ethyl acetate 80g

[0433] 0.5 g of the composition is applied to 1 g of clean, dry hair tresses. The tress was immediately dried with a hair dryer at a temperature of 80° C. for 1 minute while combing continuously throughout the drying period. Colored tresses are obtained in which the hairs are separated and the color is shampoo-firm.

Embodiment 2

[0435] Prepare the following compositions:

[0436] 40% isobutyl methacrylate / bis-hydroxypropyl dimethicone acrylate copolymer in isododecane sold under the name Granacrysil BMAS by Grant Industries 25g

[0437] Mica-iron oxide mother-of-pearl sold under the trade name Prestige SoftBronze by Eckart

[0438] 10g

[0439] α,ω-Dihydroxylated Dimethicone / Cyclopentasiloxane (14.7 / 85.3) sold under the name DC1501 Fluid by Dow Corning 50g

[0440] Isododecane 15g

[0441] 0.5 g of the composition is applied to 1 g of clean, dry hair tresses. After a dwell time of 2 minutes, the tress is dried with a hair dryer at a temperature of 80° C. for 2 minutes. Colored tresses are obtained in which the hairs are separated and the color is shampoo-firm.

Embodiment 3

[0443] Prepare the following compositions:

[0444] by the National Starch company under the trade name Dermacryl Acrylic acid / isobutyl methacrylate / ethyl methacrylate / n-tert-octyl acrylamide copolymer sold by LT

[0445] 10g

[0446] Mica-iron oxide mother-of-pearl sold under the trade name Prestige Soft Bronze by Eckart

[0447] 10g

[0448] α,ω-Dihydroxylated Dimethicone / Cyclopentasiloxane (14.7 / 85.3) sold by Dow Corning under the name DC1501 Fluid 40g

[0449] Ethanol 40g

[0450] 0.5 g of the composition is applied to 1 g of clean, dry hair tresses. After a dwell time of 2 minutes, the lock was dried with a hair dryer at a temperature of 80° C. for 2 minutes while brushing the lock during drying. Colored tresses are obtained in which the hairs are separated and the color is shampoo-firm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com