Stewpot handle bending strength test machine

A bending strength, testing machine technology, applied in the direction of elasticity testing, machine/structural component testing, measuring devices, etc., can solve problems such as missed inspection accidents, personal injury, poor performance, etc., to prevent substandard products, guarantee the use of Safe and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings.

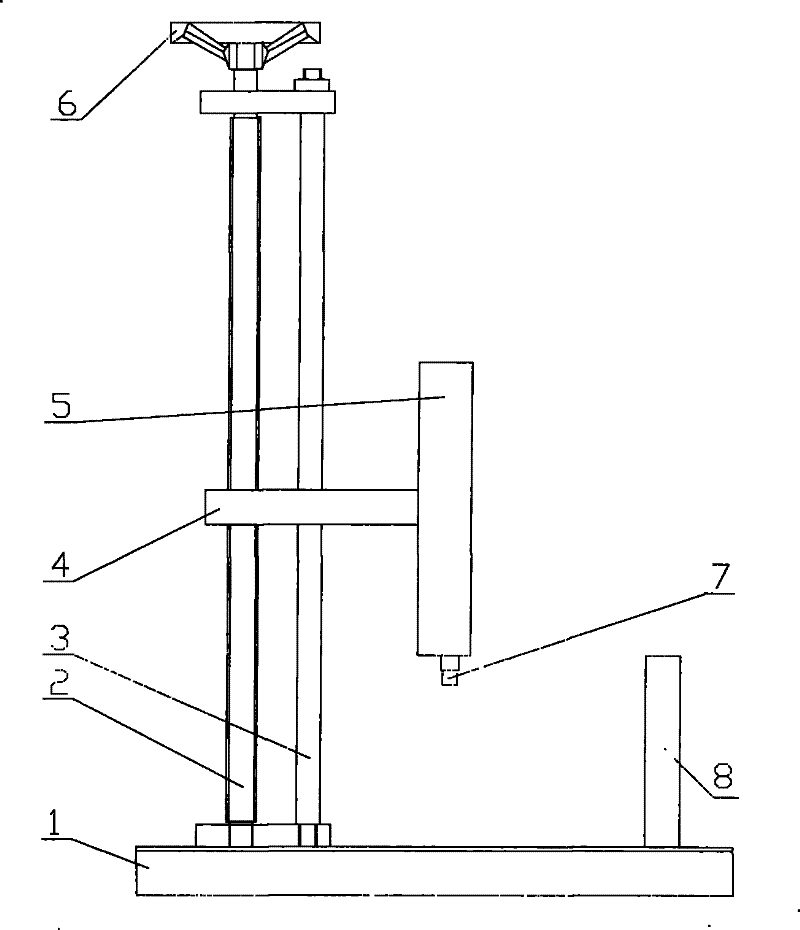

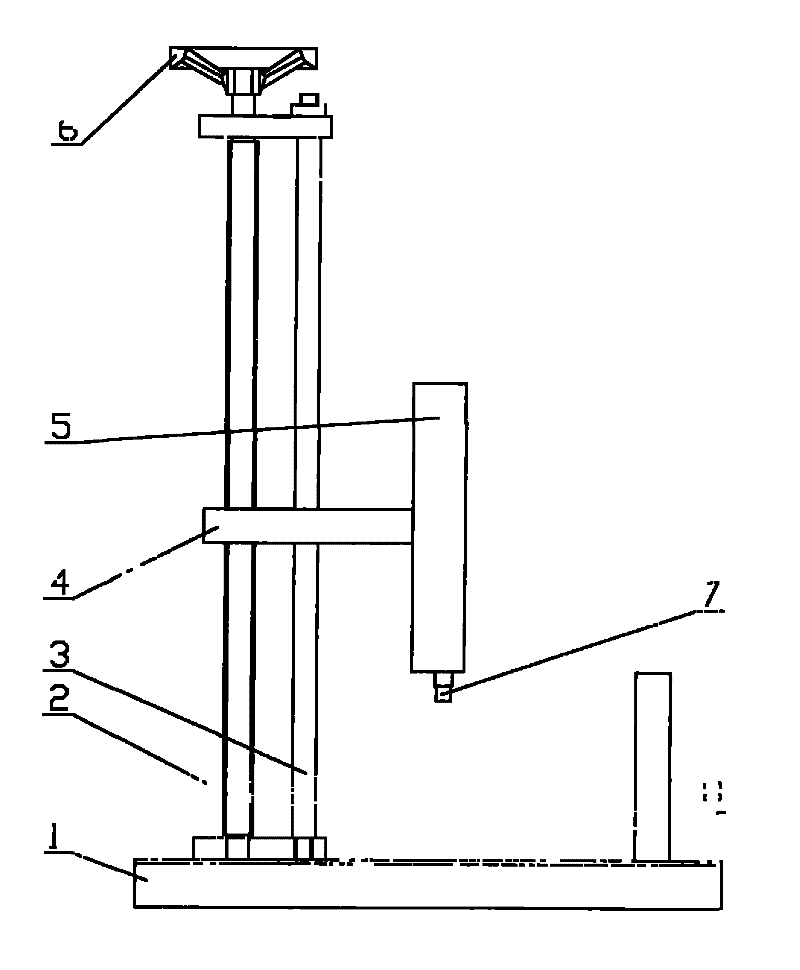

[0014] figure 1 It is a structural schematic diagram of a bending strength testing machine for a cauldron handle of the present invention. As shown in the figure, the pan handle bending strength testing machine of the present invention includes a test platform 1, a screw 2, a guide post 3, a moving plate 4, a tension meter 5, a hand wheel 6 and a fixed plate 8, etc., and the guide post 2 is installed vertically. At one end of the test platform 1, a positioning plate is fixed on the upper end of the guide post 2. The leading screw 2 is parallel to the guide post 3, the upper end passes through the positioning plate, and is movably connected with the positioning plate, and the lower end is supported by the test platform 1, and is movably installed on the test platform 1 and can rotate. A hand wheel 6 is fixedly installed on the uppermost end of the leading screw 2 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com