Assemblies in the printing unit of a rotary press

A combined device, printing machine technology, applied in the direction of rotary printing machine, lithographic rotary printing machine, printing machine roll coat, etc., to achieve good ink absorption, high wear resistance and aging resistance, good ink release effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

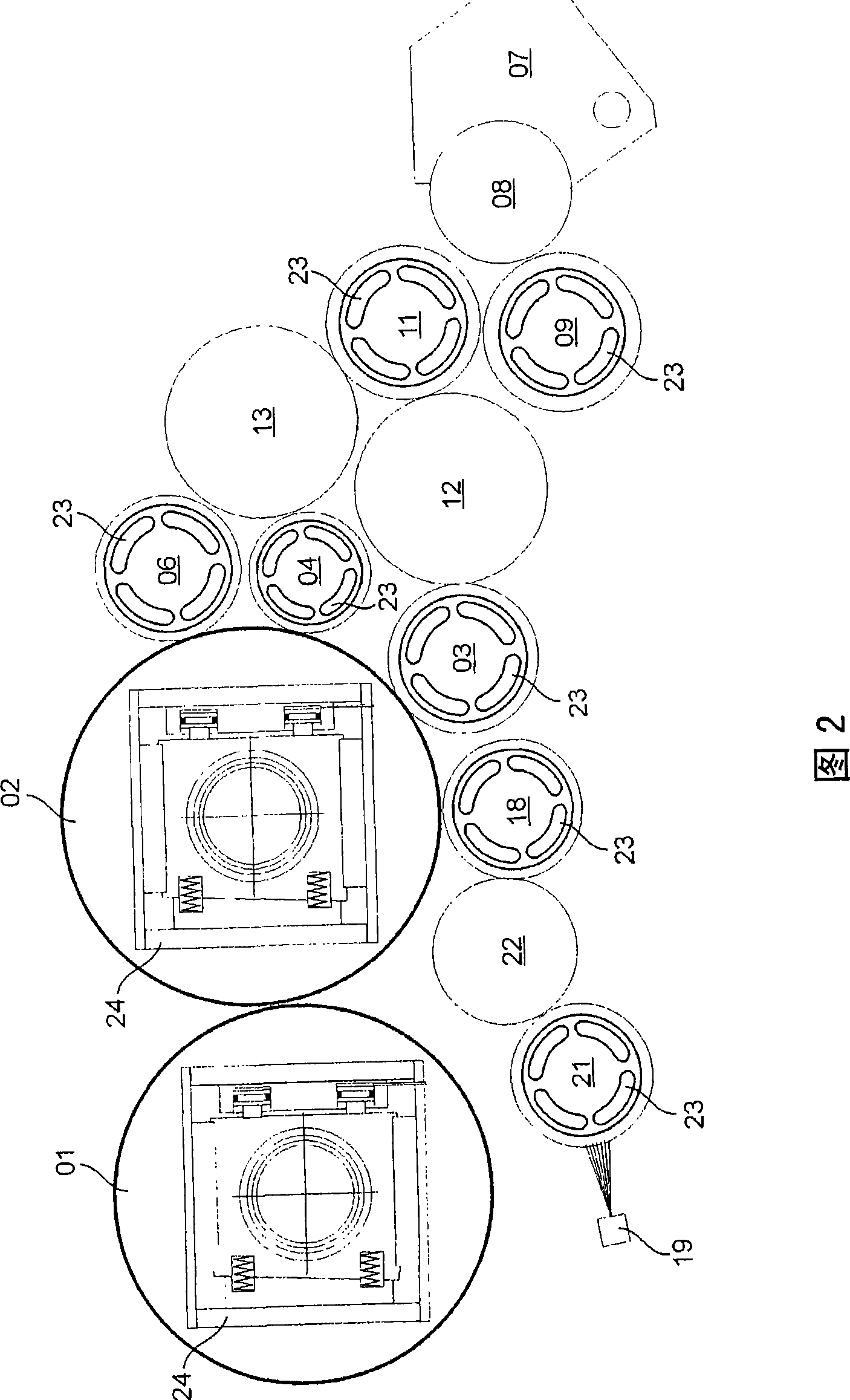

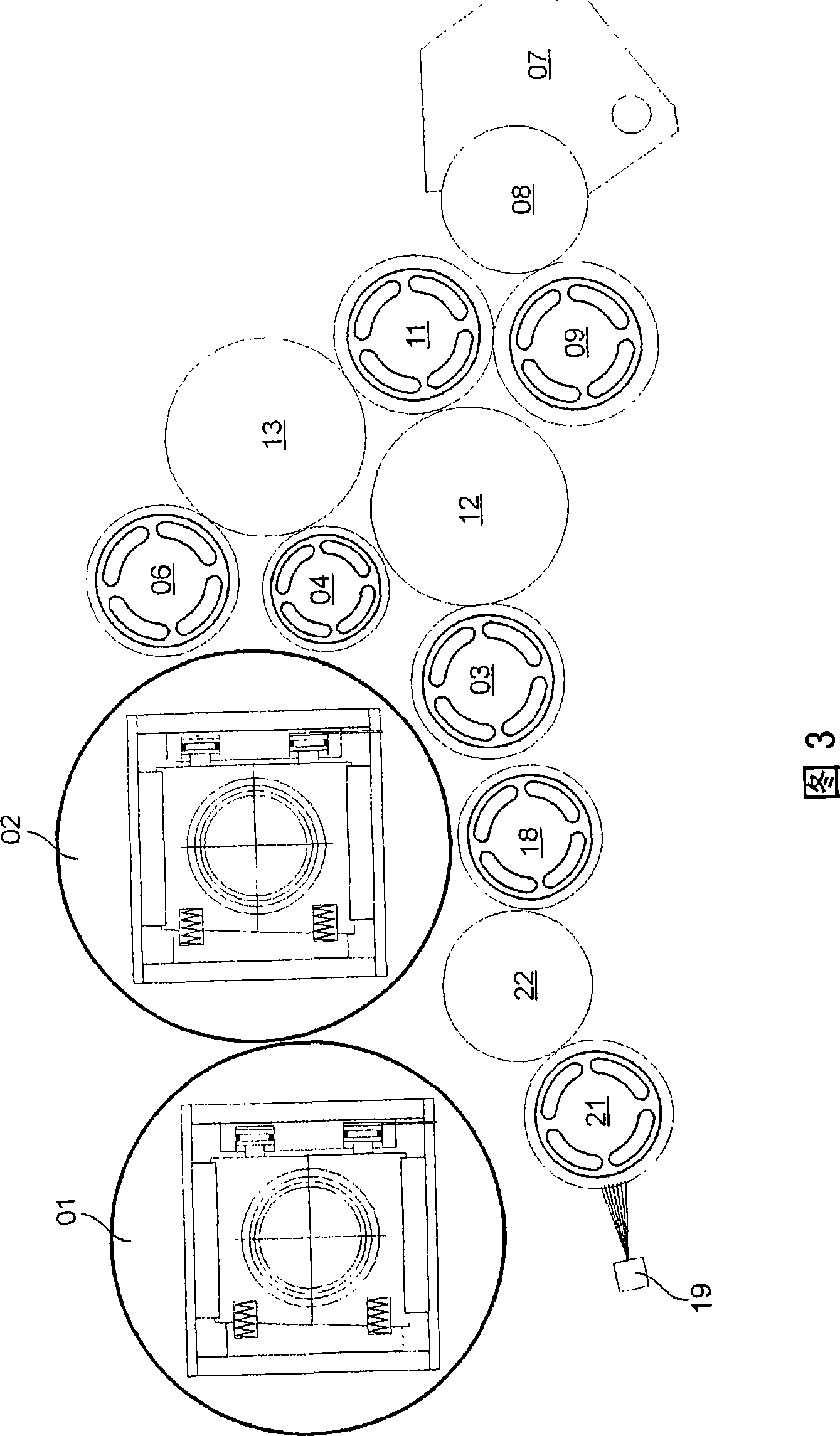

[0032] FIG. 1 shows an example of a part of a printing unit of a rotary printing press. In the example shown, the rotary printing press operates in a wet offset process. Its application is especially envisioned in newspaper printing. The printing unit has at least one transfer cylinder 01 as printing unit cylinder 01 ; 02 and a forme cylinder 02 cooperating with the transfer cylinder 01 . With each rotation of the transfer cylinder 01 , at least one printed image is produced on a printing material (not shown), preferably on a material web, in particular a paper web. In the operating situation of the printing unit as shown in FIG. 1 , at least one inking unit and one dampening unit are located close to the plate cylinder 02 .

[0033] The inking unit has a plurality, preferably at least three, inking rollers 03 ; 04 ; 06 , which abut against the plate cylinder 02 during the production process of the operation of the rotary printing press. A plurality of rollers 09 ; 11 ; 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com