Method for detecting sizing percentage of slashing by applying near-infrared spectrum technology

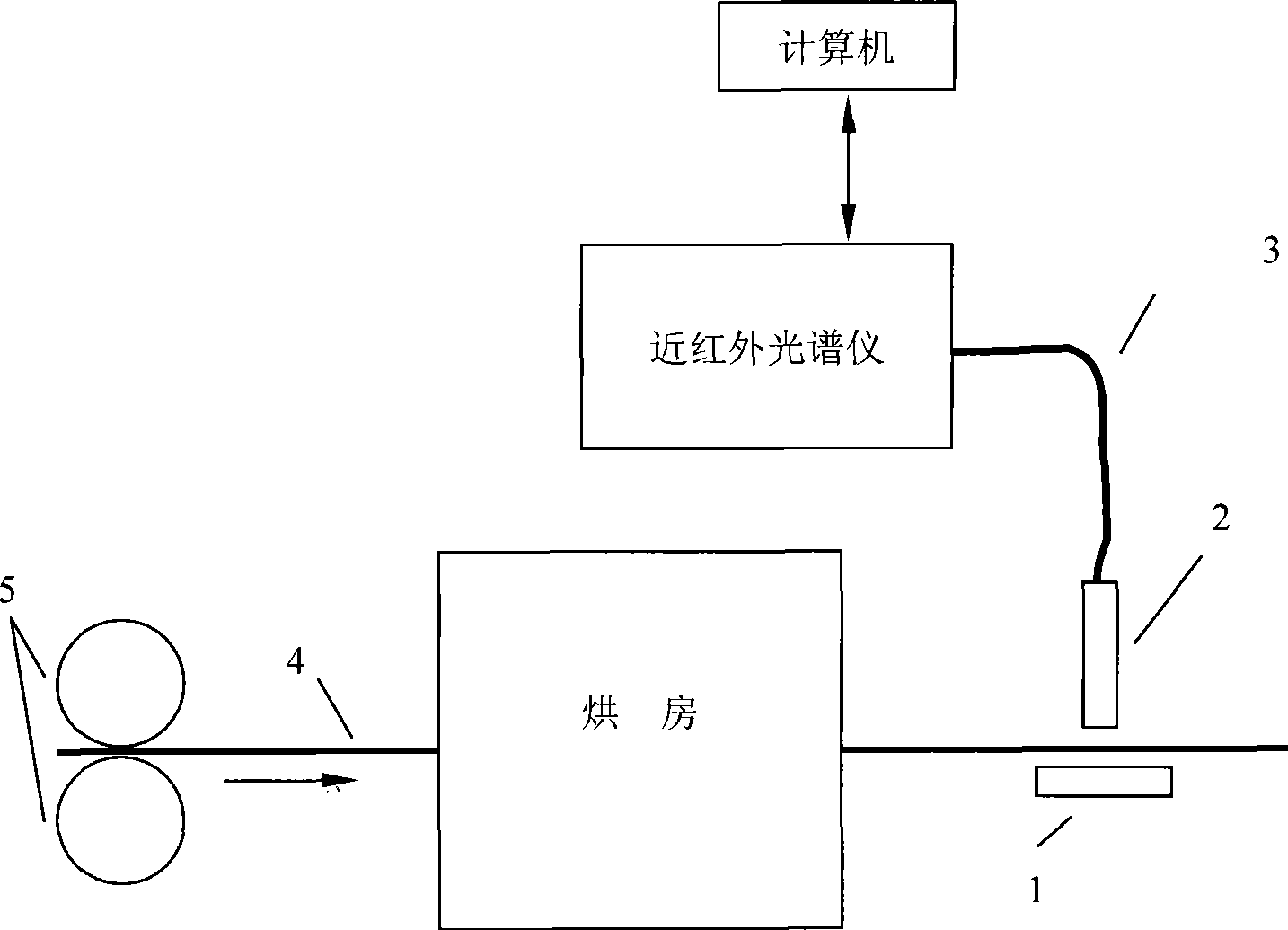

A technology of near-infrared spectroscopy and technical detection, which is applied in the field of detection of sizing rate of sizing yarn, and can solve problems such as unreported

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0030] Example: Near-infrared detection of pure cotton yarn sizing rate

[0031] 1. Warp sample collection:

[0032] In order to establish the near-infrared calibration model of warp sizing rate, firstly, pure cotton warp yarn samples of different specifications were collected. The sample set includes five kinds of pure cotton single yarns with a fineness of 9.7tex, 14tex, 23tex, 28tex, and 32tex. The yarns are package yarns processed on automatic winding machines, and they come from different batches of products from three different cotton spinning enterprises. .

[0033] 2. Sizing selection and mixing:

[0034] Choose the mixed size with grafted starch and PVA as the main size, the mixing ratio is 100:50, 100:20 respectively, the former is used for warp sizing of low special (9.7tex, 14tex), the latter is used for medium high special (23tex) , 28tex, 32tex) warp sizing.

[0035] 3. Sizing:

[0036] The sizing operation is performed on the warp yarns on the digital autom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com