Flexible wiring board, method of producing the same and imaging device

A technology of wiring boards and flexible substrates, applied in the field of flexible wiring boards, which can solve the problems of maintaining folded parts and the difficulty of flexible wiring boards, etc., and achieve the effect of suppressing reaction force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Hereinafter, a flexible wiring board and an imaging device according to a first embodiment of the present invention will be described with reference to the drawings.

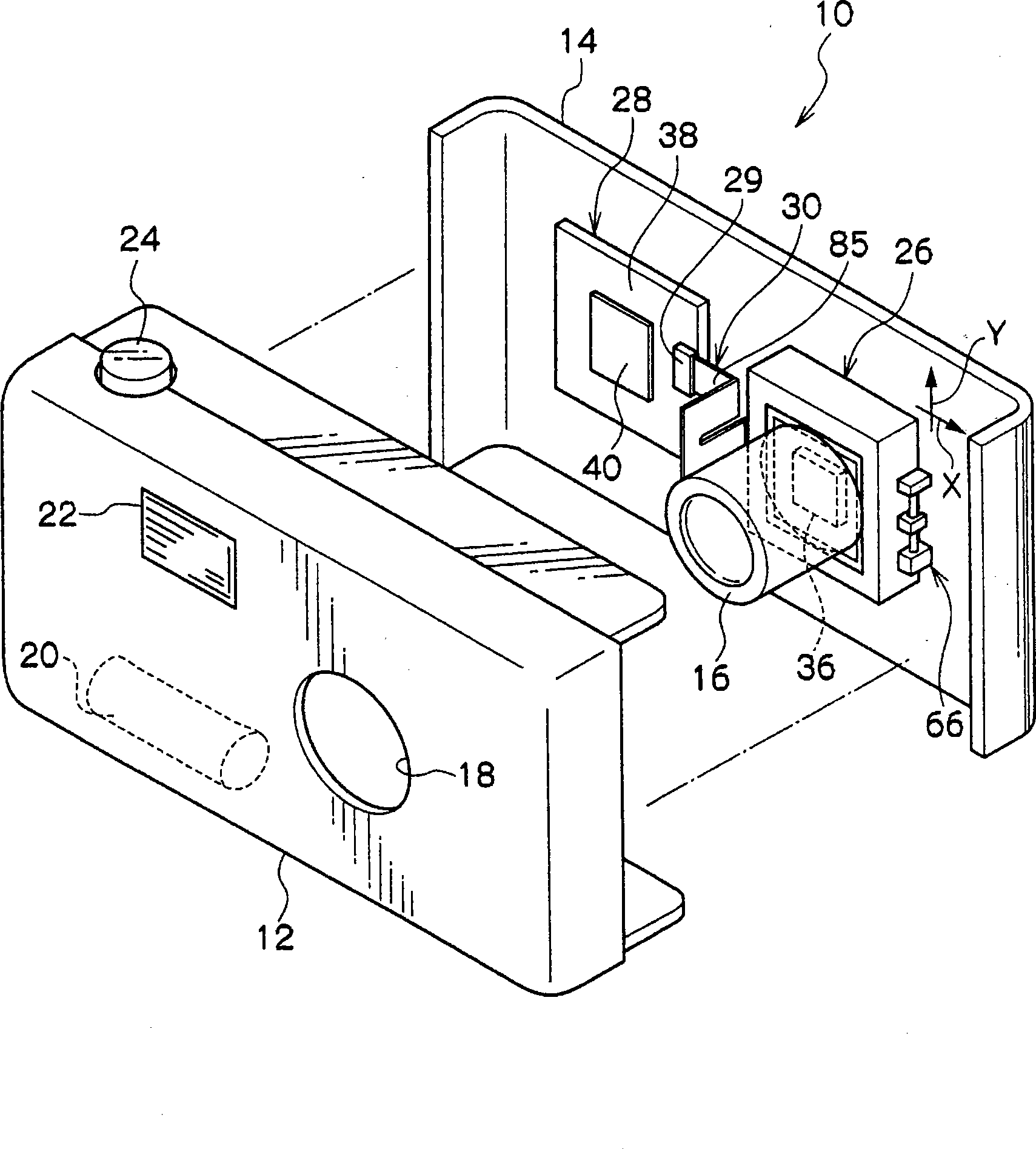

[0035] figure 1 A digital video camera 10 as an imaging device is shown. The digital video camera 10 has a front cover 12 and a rear cover 14 that constitute the main body of the digital video camera 10.

[0036] The front cover 12 has an opening into which the lens 16 is inserted for forming an image of a subject. The inside of the front cover 12 is provided with: a power supply unit 20, which is used to provide power to various parts of the digital video camera 10; a flash device 22, which emits light as needed during shooting; and a switch button 24, which is used to start the imaging operation .

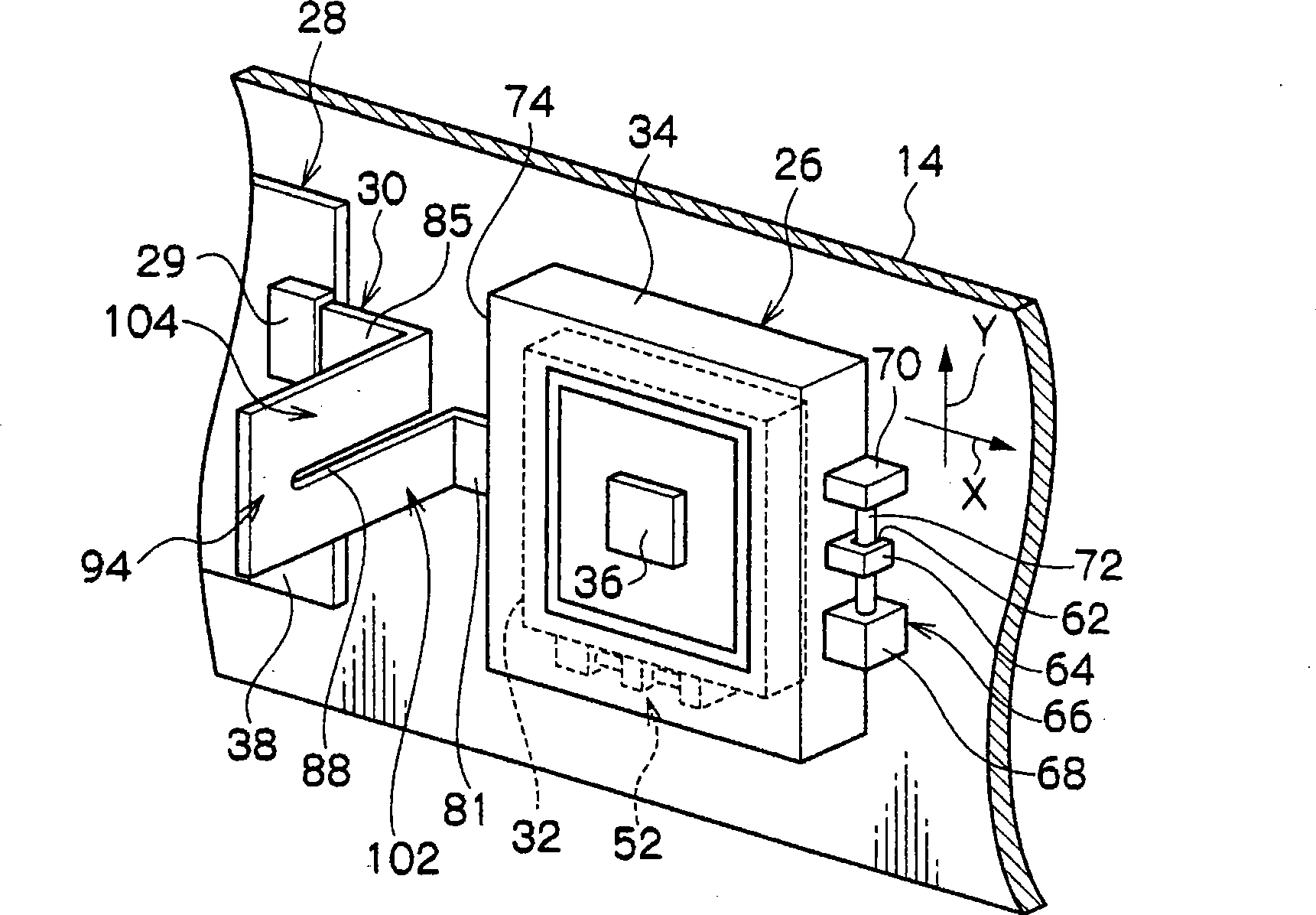

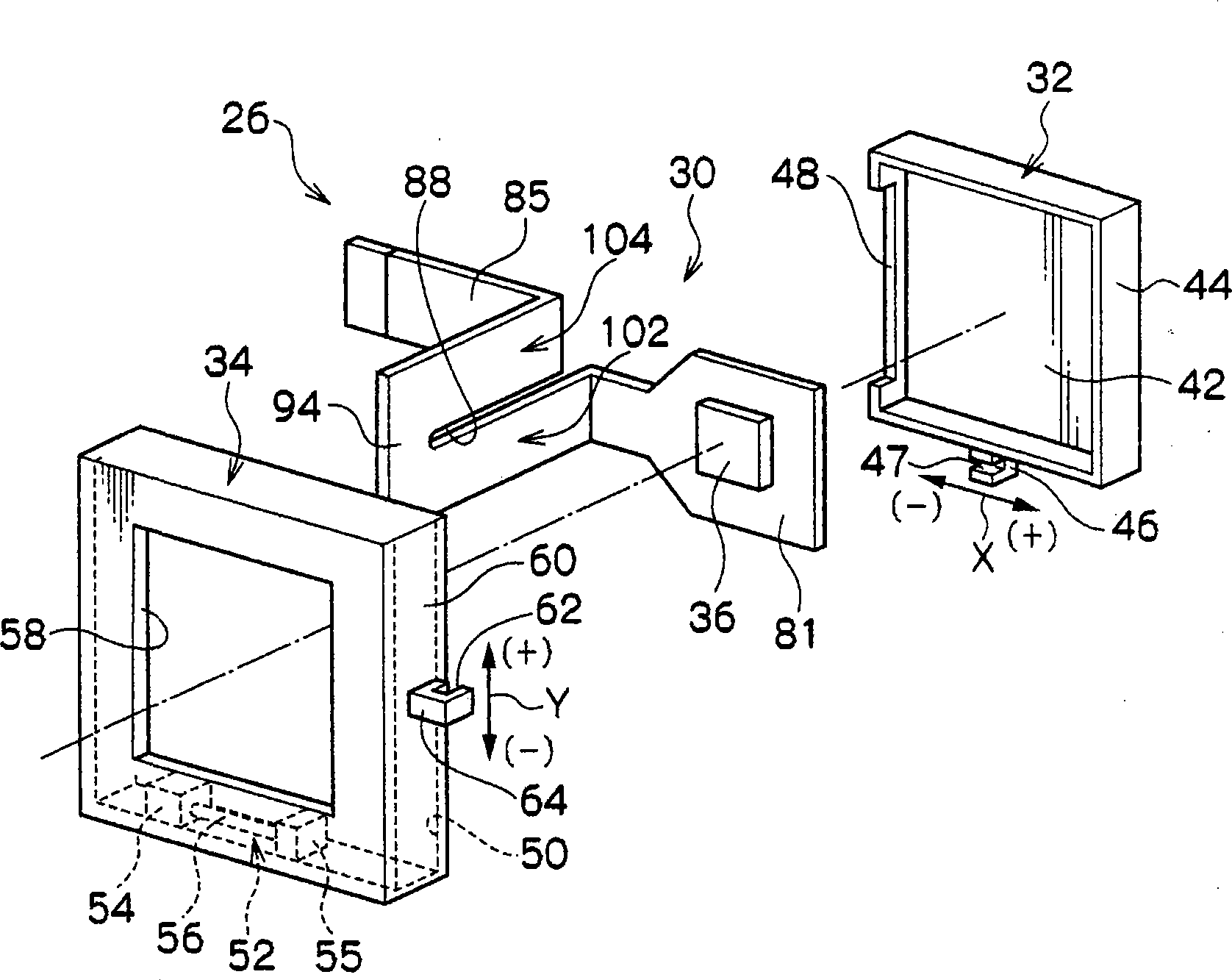

[0037] On the other hand, an imaging unit 26 having a CCD (Charge Coupled Device) 36 is provided on the inner side of the back cover 14 which receives light incident from the lens 16 and converts the light int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com